A metal roof system

A technology for metal roofs and metal houses, which is applied to roofs, roof coverings, and roofs using flat/curved panels, etc., can solve the problems of increasing the cost of raw materials for main purlins, high labor intensity for operators, and low erection efficiency. Construction costs and steps, improving construction efficiency, easy processing and deformation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

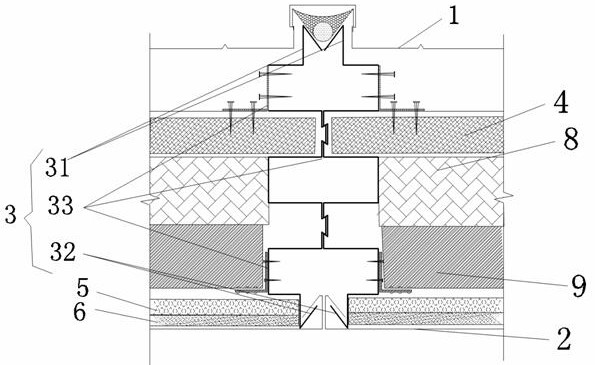

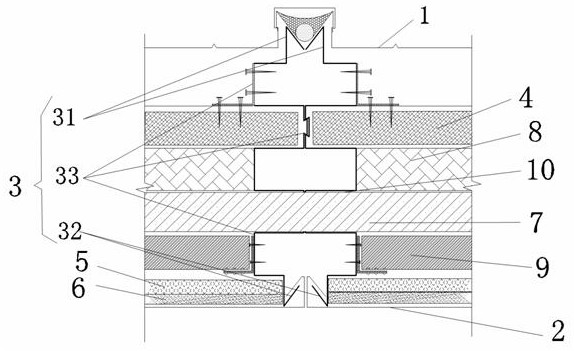

[0053] This example provides a metal roof system suitable for plane without curves, and the specific connection adopts the first connection structure; in this embodiment, please refer to figure 1 and figure 2 shown in which, figure 1 A schematic cross-sectional view showing the location of the main purlin; figure 2 It is a schematic cross-sectional view without showing the location of the main purlin. In this embodiment, the metal roof system includes a metal roof on the upper part of the main purlin and a roof bottom plate on the lower part of the main purlin. The metal roof is formed by sequentially connecting metal roof panels 1 of P blocks (P is an integer greater than or equal to 2). In the embodiment, after the adjacent metal roof panels 1 are in contact, weather-resistant adhesive is used to seal and connect the joints between the adjacent metal roof panels 1 and the following first connection structure, and finally the contact places are fastened by the aluminum-ma...

Embodiment 2

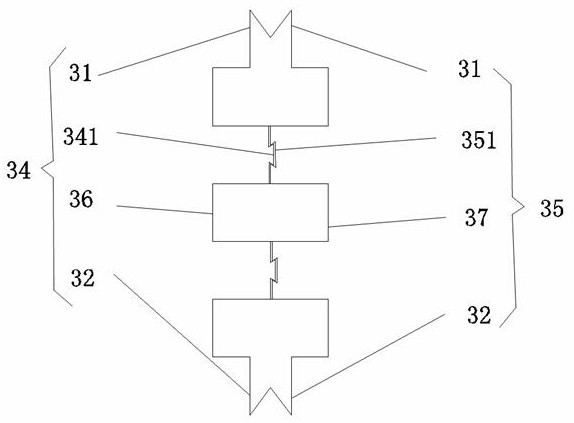

[0060] This embodiment is a further improvement on the basis of embodiment 1. The difference between this embodiment and embodiment 1 is that this embodiment is to further optimize the first connection structure in embodiment 1 to further improve the first connection structure. The supporting effect of a connection structure, the first connection structure is a plate-type or box-type structure, and the first connection structure includes an upper bite part, a lower fastening part, and a support part. In this embodiment, the first connection structure is preferably a plate structure.

[0061] The first connecting structure of the present embodiment comprises the left panel purlin 34 and the right panel purlin 35, such as Figure 3a , Figure 3b , Figure 3c , Figure 3d As shown, among them, Figure 3a and Figure 3c It is a schematic diagram of the bite connection between the left panel purlin 34 and the right panel purlin 35 in the first connection structure; Figure 3b...

Embodiment 3

[0069] This example provides a metal roof system suitable for multi-curved structures, using the second connection structure; please refer to Figure 4 As shown, in this embodiment, please refer to Figure 4 As shown, the metal roof system includes the metal roof on the upper part of the main purlin and the roof bottom plate on the lower part of the main purlin. The metal roof is formed by sequentially connecting P blocks (P is an integer greater than or equal to 2) metal roof panels 1. In this embodiment After the adjacent metal roof panels 1 are in contact, weather-resistant adhesive is used to seal and connect the joints between the adjacent metal roof panels 1 and the second connection structure described below, and finally the contact places are fastened and connected by an aluminum-magnesium-manganese alloy buckle cover. The roof bottom plate is formed by sequentially connecting Q blocks (Q is an integer greater than or equal to 2) suspended floor plates 2 .

[0070] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com