Plasma flame catalytic activation coal powder burner for cement plant

A pulverized coal burner and catalytic activation technology, which is applied to burners, burners, plasma and other directions of burning powder fuel, can solve the problem of unsatisfactory pulverized coal burnout rate in time, stable operation of pollutant kiln system, and combustion performance. The problem of poor reaction activity, etc., can achieve the effect of strong adaptability to coal quality fluctuation, improving combustion efficiency and timely burning rate, and facilitating improvement and transformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

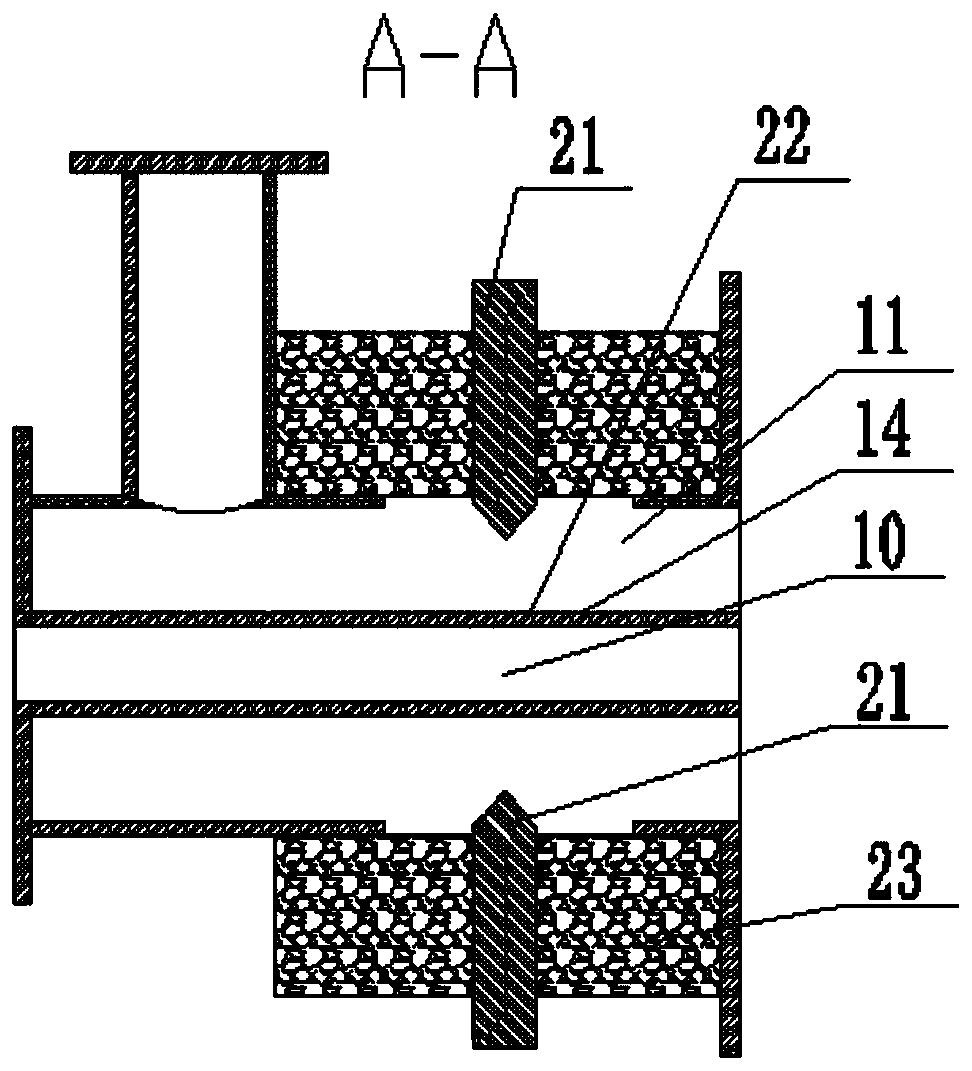

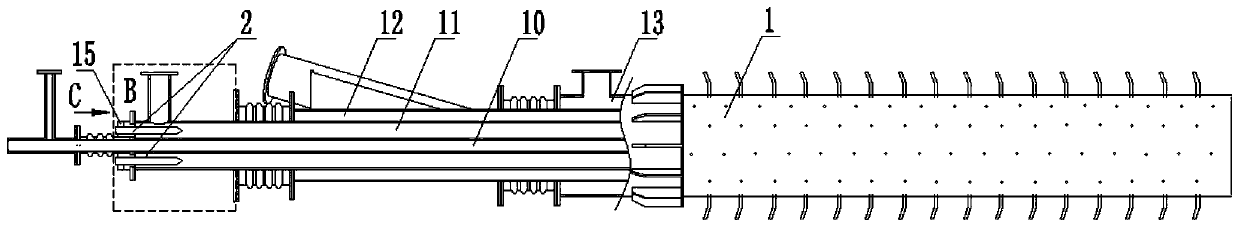

[0031] refer to Figure 3-5 , the discharge part 21 of the plasma flame catalytic device 2 described in this embodiment is fixed on the end 15 of the internal air duct of the burner through the insulating part 23; the rear end of the insulating part 23 is also provided with a magnetic control part 25, and the magnetic Control part 25 is made of electromagnetic coil, is installed in insulation part 23 rear parts.

[0032] All the other are the same as embodiment 1

Embodiment 3

[0034] refer to Figure 6-7 , the discharge part 21 of the plasma flame catalytic device 2 described in this embodiment is respectively fixed on the wall 14 of the inner air duct of the burner and the end part 15 of the inner air duct through the insulating member 23 .

[0035] All the other are the same as embodiment 1

Embodiment 4

[0037] refer to Figure 8-10 , the plasma flame catalytic device 1 of the present embodiment is arranged at the exit 16 of the internal air duct, the discharge part 21 of the plasma flame catalytic device 2 is a ring electrode, and the conductive part 22 is a ring electrode, and the discharge part 21 passes through The insulating part 23 is connected to the conductive part 22 , and the power supply device is connected to the discharge part 21 and the conductive part 22 through the cable provided in the central air duct 10 .

[0038] All the other are the same as embodiment 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com