Low-consumption catalytic separation wastewater treatment method

A technology for wastewater treatment and low consumption, which is applied in water/sewage treatment, natural water treatment, water treatment parameter control, etc. The effect of improving dissolved gas characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) will contain COD cr 1200mg / L, BOD 5 50mg / L, 350mg / L SS, 100mg / L oil content, 150mg / L volatile phenol, 50mg / L total phosphorus, and 100mg / L total nitrogen pass through the grid well, and then the wastewater Discharge into the grease trap, separate the suspended solids in the wastewater and discharge the suspended solids.

[0035] (2) The active energy generating device is activated by an electric field to generate OH - Active gas such as free radicals, the active gas containing free radicals is dissolved in water at 0.25MPa through the dissolved air system to produce active dissolved air water.

[0036] (3) Add 0.5mg / L AP demulsifier to the wastewater for demulsification treatment, and add 0.2mg / L diatomite flocculant for sedimentation treatment.

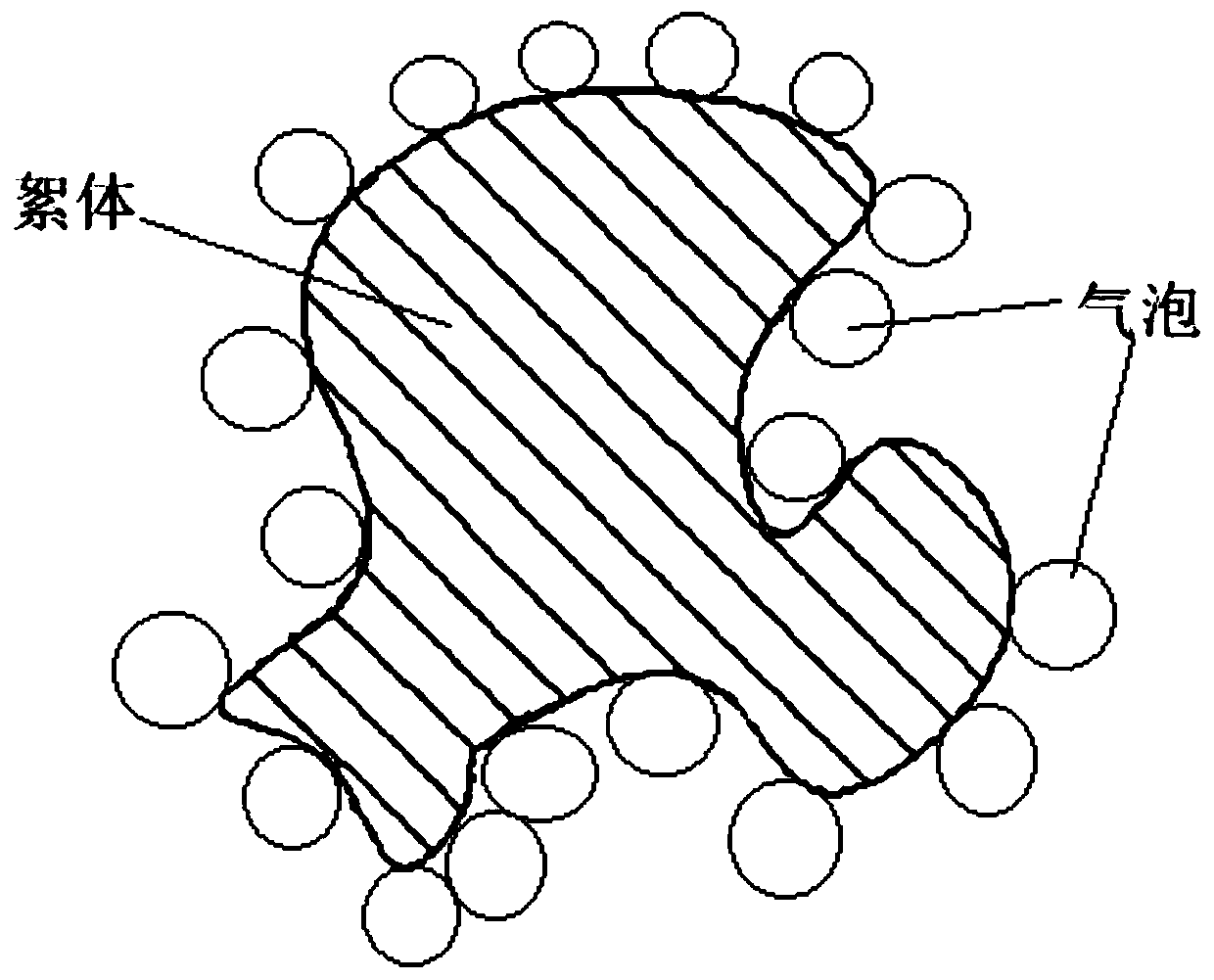

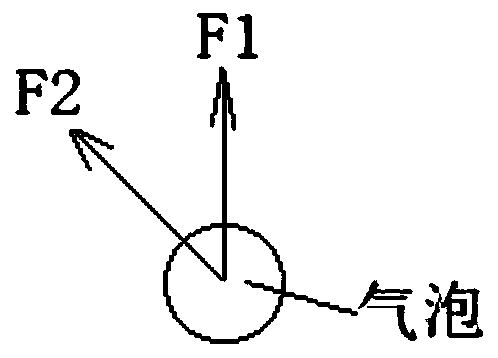

[0037] (4) Send the wastewater separated from the suspended matter into the air flotation tank, and the dissolved air water (accounting for 20% of the volume of the wastewater) is evenly released into the air flotation ...

Embodiment 2

[0045] (1) will contain COD cr 800mg / L, BOD 5 Wastewater with a concentration of 100mg / L, SS of 300mg / L, oil content of 20mg / L, total phosphorus of 4mg / L, and total nitrogen of 300mg / L passes through the grid well, and then discharges the waste water into the grease trap to separate the waste water suspended matter and discharge the suspended matter.

[0046] (2) The active energy generating device is activated by an electric field to generate OH - Active gas such as free radicals, the active gas containing free radicals is dissolved in water through the dissolved air system at 0.3MPa to produce active dissolved air water.

[0047] (3) Send the wastewater separated from the suspended matter into the air flotation tank, and the dissolved air water (accounting for 20% of the volume of the wastewater) is evenly released into the air flotation tank through the dissolved air releaser evenly arranged at the bottom of the air flotation tank, and the release pressure is 0.3MPa , th...

Embodiment 3

[0054] (1) will contain COD cr 2500mg / L, BOD 5 The wastewater is 450mg / L, SS is 50mg / L, oil content is 20mg / L, total phosphorus is 15mg / L, and total nitrogen is 100mg / L. The wastewater passes through the grid well, and then the wastewater is discharged into the grease trap to separate the wastewater Suspended matter in and discharged.

[0055] (2) The active energy generating device is activated by an electric field to generate OH - The active gas containing free radicals is dissolved in water through the dissolved air system at 0.33MPa to produce active dissolved air water.

[0056] (3) Add 2 mg / LAP type demulsifier to the wastewater for demulsification treatment, and add 3 mg / L polyaluminum chloride flocculant for sedimentation treatment.

[0057] (4) Send the wastewater separated from the suspended matter into the air flotation tank, and the dissolved air water (accounting for 15% of the volume of the wastewater) is evenly released into the air flotation tank through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com