A kind of high foaming reinforced film

A technology of reinforcing film and high foaming, applied in the direction of adhesives, epoxy resin glue, rubber-derived glue, etc., can solve the problems of fixed thickness and unsatisfactory reinforcement effect, etc., to improve the bonding force, damping and shock absorption effect. , good random effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

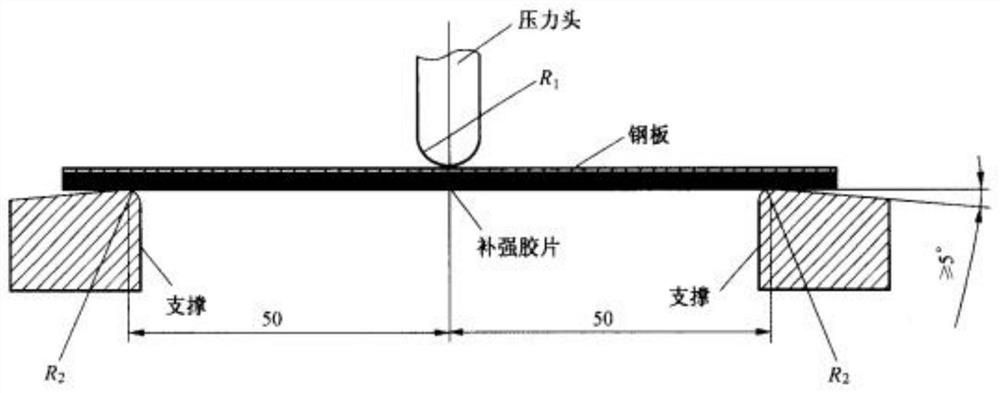

Image

Examples

Embodiment 1

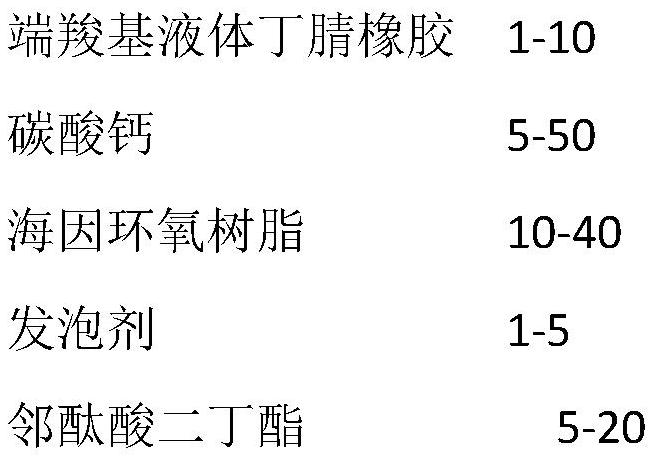

[0019] A kind of high-foaming reinforcing film, is made up of each material of following mass parts:

[0020]

[0021] In this embodiment, the epoxy value of hydantoin epoxy resin is 0.2602mol / 100g, and the average molecular weight is 769; the content of acrylonitrile in the carboxyl-terminated liquid nitrile rubber is 15%.

Embodiment 2

[0023] A kind of high-foaming reinforcing film, is made up of each material of following mass parts:

[0024]

[0025] In this embodiment, the epoxy value of hydantoin epoxy resin is 0.2602mol / 100g, and the average molecular weight is 769; the content of acrylonitrile in the carboxyl-terminated liquid nitrile rubber is 15%.

Embodiment 3

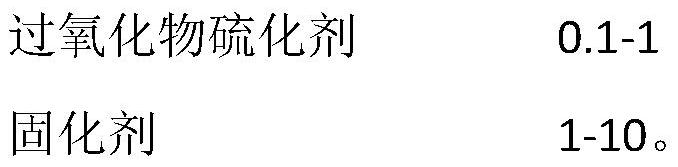

[0027] A kind of high-foaming reinforcing film, is made up of each material of following mass parts:

[0028]

[0029]

[0030] In this embodiment, the epoxy value of hydantoin epoxy resin is 0.2602mol / 100g, and the average molecular weight is 769; the content of acrylonitrile in the carboxyl-terminated liquid nitrile rubber is 15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com