High-hardness electromagnetic shielding aluminum alloy

An electromagnetic shielding and aluminum alloy technology, applied in the fields of magnetic field/electric field shielding, electrical components, metal material coating technology, etc., can solve the problems of poor hardness and electromagnetic shielding, and achieve the goal of ensuring toughness, improving performance, and improving alloy hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

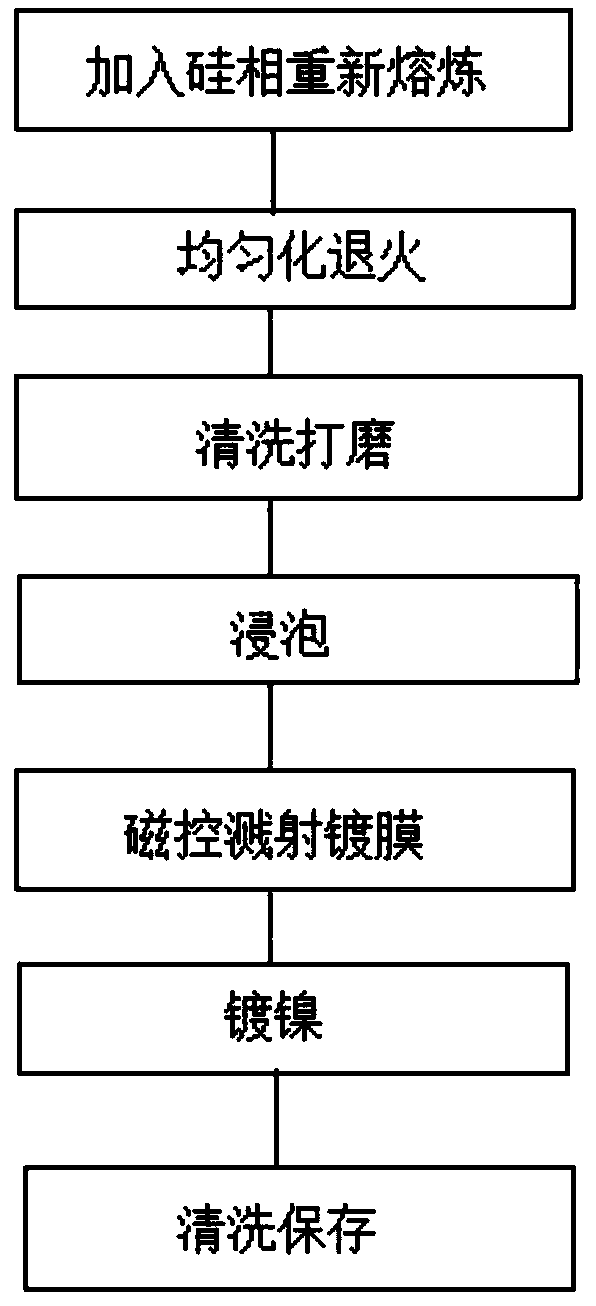

[0027] Please see figure 1 , is a flow diagram of a preferred embodiment of a high-hardness electromagnetic shielding aluminum alloy of the present invention, a high-hardness electromagnetic shielding aluminum alloy, and the preparation steps of the high-hardness electromagnetic shielding aluminum alloy are as follows:

[0028] Step 1: add the silicon phase and remelt, first prepare the Al-xCu-yMg-zZn alloy melt, and then mix the Al-xCu-yMg-zZn alloy melt with the Al-12.6Si master alloy evenly at the melting temperature, After mixing, it is poured into a metal mold at room temperature to prepare Mg-11Al-1.0Cu-0.05Zn-mSi aluminum alloy;

[0029] Step 2, homogenizing annealing, performing homo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com