Method and system for reducing disturbance of start and stop of double-inlet and double-outlet coal mill to denitration system

A double-in, double-out, coal mill technology, applied in the combustion method, regulating fuel supply, block/powder supply/distribution, etc., can solve the disturbance of nitrogen oxide concentration, the fluctuation of nitrogen oxide in flue gas, Measurement data lag and other problems, to achieve the effect of reducing large fluctuations, reducing disturbance intensity, and facilitating stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

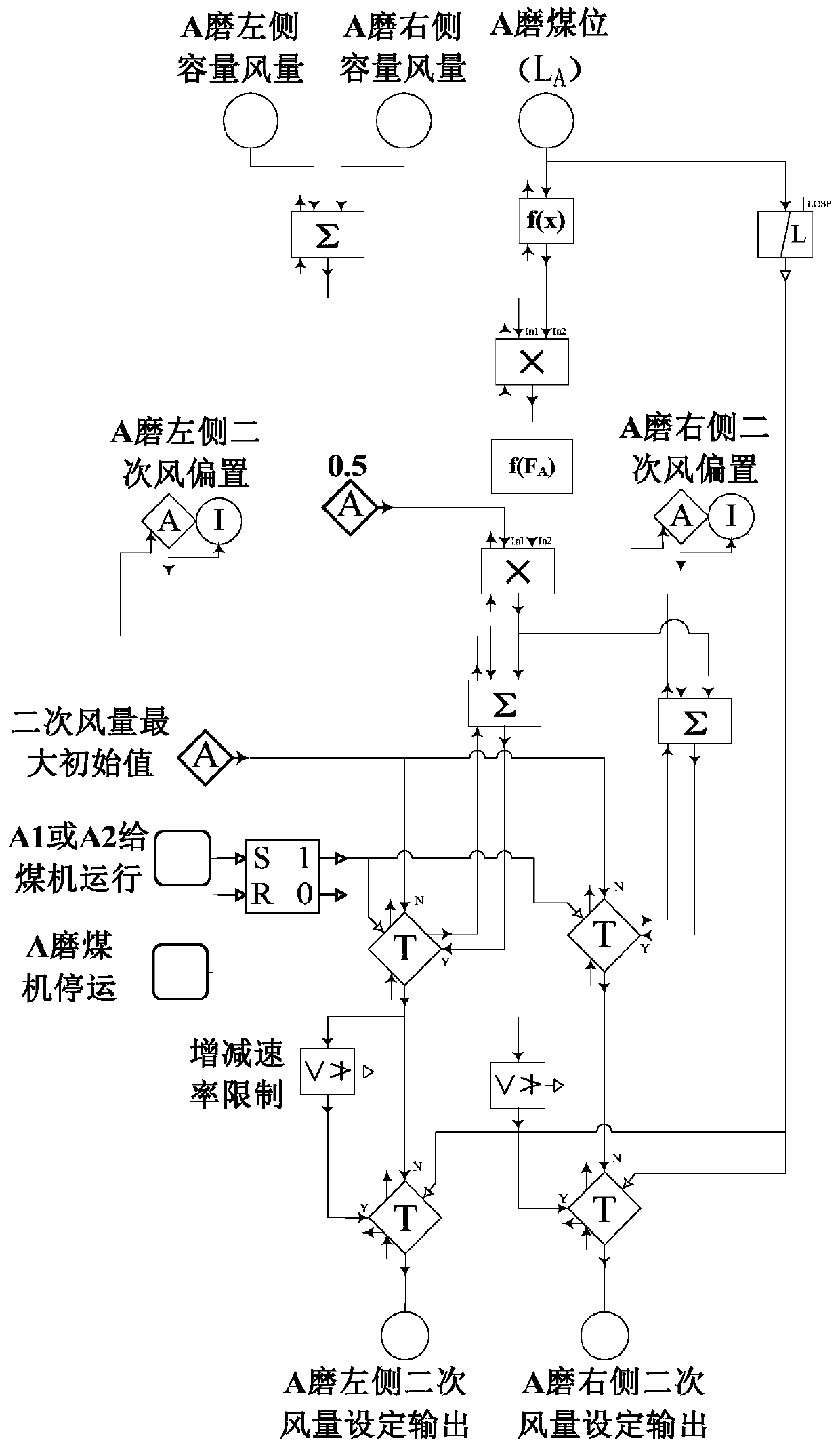

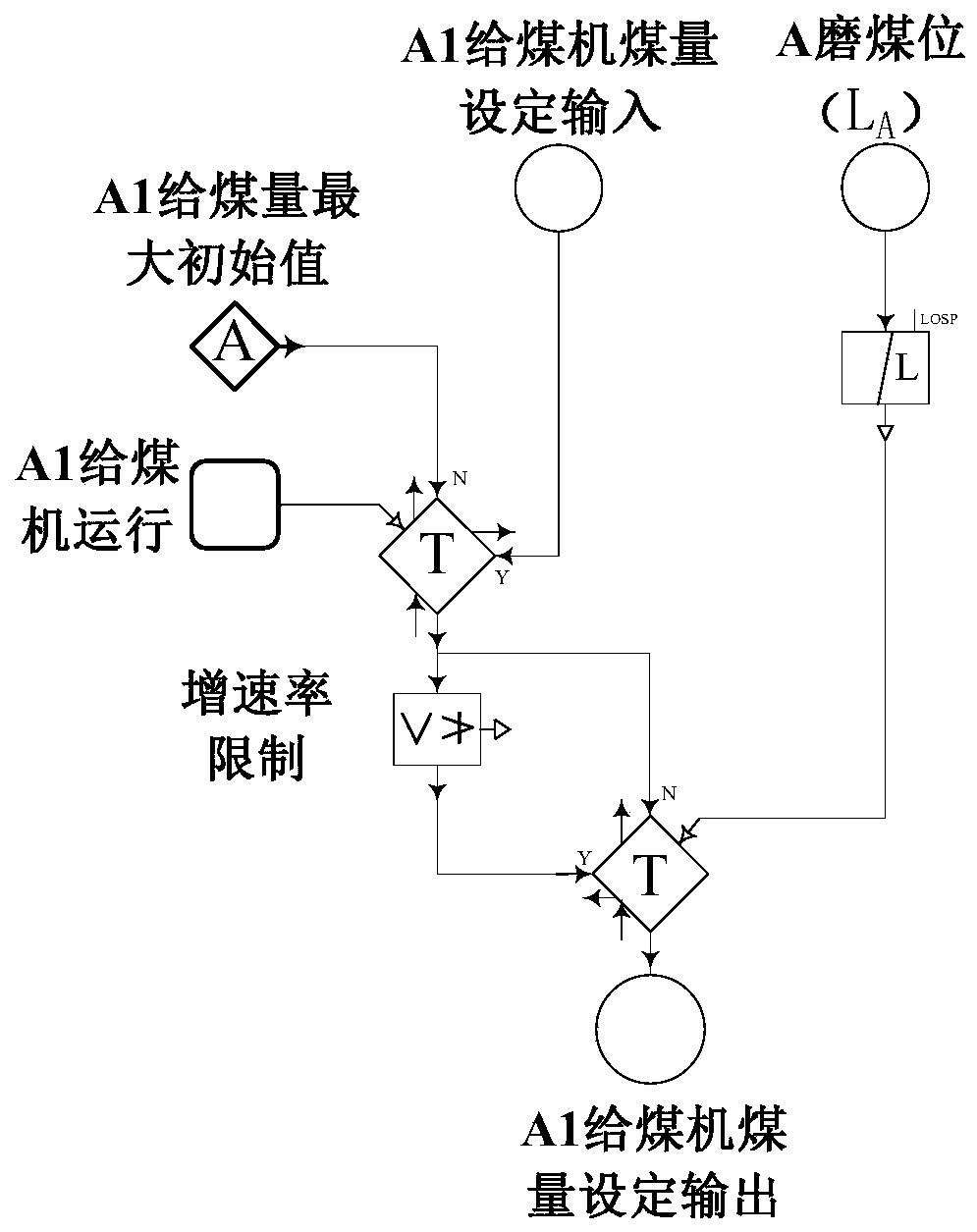

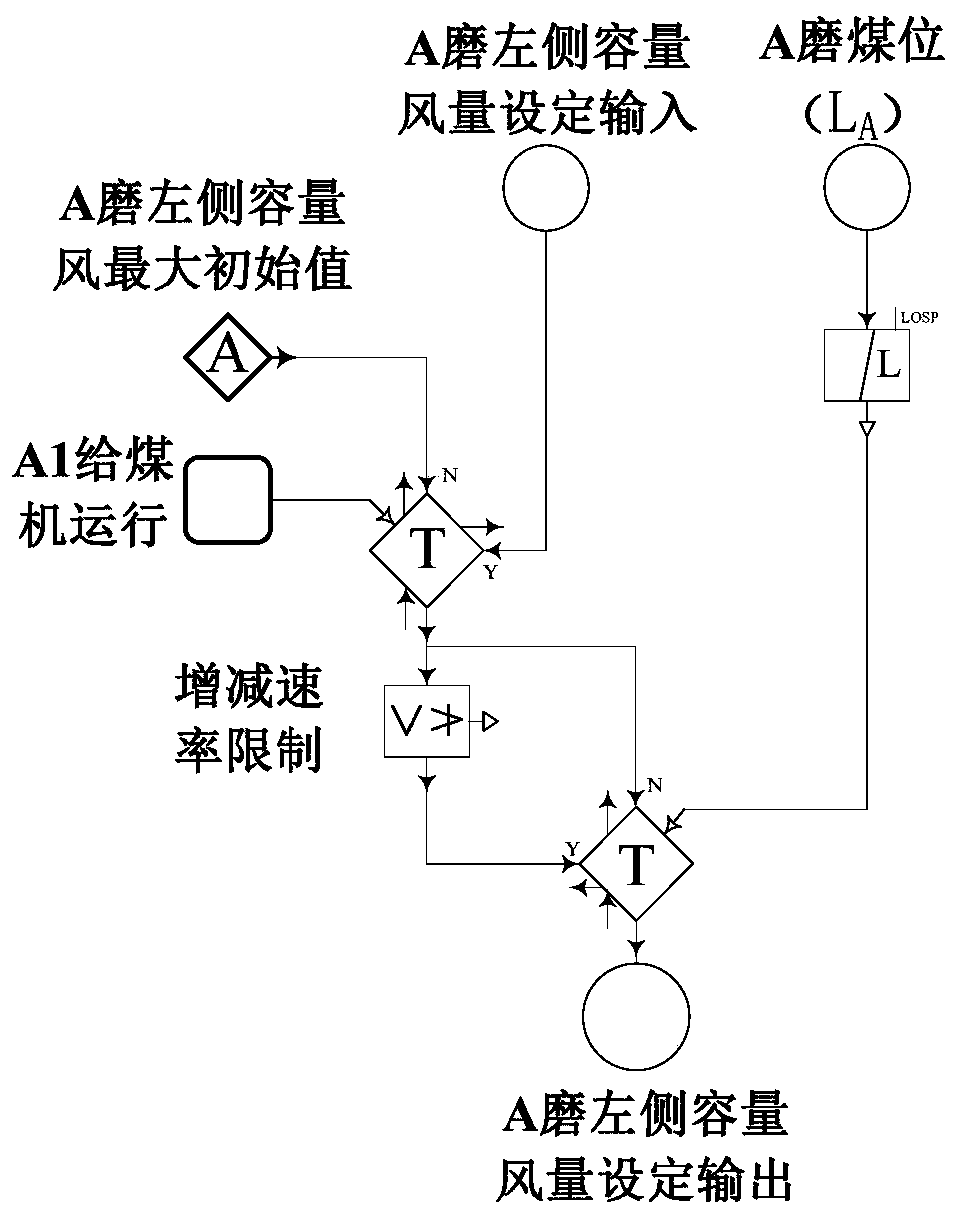

[0033] Embodiment 1 of the present disclosure provides a control method for reducing the disturbance to the denitrification system caused by the start and stop of double-inlet and double-outlet coal mills. ), the pulverizer on both sides of the pulverizer is mixed for the control of the left and right burners and the left and right secondary air baffles as an example, including the following steps:

[0034] (1) Determine the formula for calculating the capacity and air volume after the correction of the coal level

[0035] Take mill A as an example:

[0036] f A =f(L A ) f A

[0037] Among them, F A - The air volume of mill A after correction of coal level, that is figure 1 The product of the sum of the left and right volumes of the middle A mill multiplied by the function f(x);

[0038] L A —A coal grinding position;

[0039] f(L A )—the capacity air volume correction function with the coal grinding position of A as the variable, that is figure 1 In the function f(...

Embodiment 2

[0076] Embodiment 2 of the present disclosure provides a system for reducing the disturbance to the denitrification system caused by the start and stop of double-inlet and double-outlet coal mills, including:

[0077] The volume air volume acquisition module after coal level correction is configured to: obtain the volume air volume after coal level correction according to the corrected coal level of the double-inlet and double-outlet coal mill;

[0078] The proportioning function acquisition module is configured to: obtain the proportioning function of the combustion-supporting air volume and the coal level-corrected volumetric air volume according to the volumetric air volume after coal level correction;

[0079] The control module is configured to: when the double-inlet and double-outlet coal pulverizer and the corresponding coal feeder are started, the coal volume of the coal feeder is controlled according to the preset maximum initial coal feed volume and the increase rate ...

Embodiment 3

[0092] Embodiment 3 of the present disclosure provides a medium on which a program is stored. When the program is executed by a processor, the method for reducing the disturbance to the denitrification system by the start and stop of the double-inlet and double-outlet coal mill as described in Embodiment 1 of the present disclosure is implemented. in the steps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com