Treatment system for high-salinity and high-COD industrial wastewater

A technology for industrial wastewater and high salinity, applied in aerobic and anaerobic process treatment, water/sewage treatment, biological water/sewage treatment, etc., can solve high risk, large amount of chemical input, and large amount of sludge generation and other issues, to achieve the effect of eliminating hazardous waste and realizing zero discharge of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

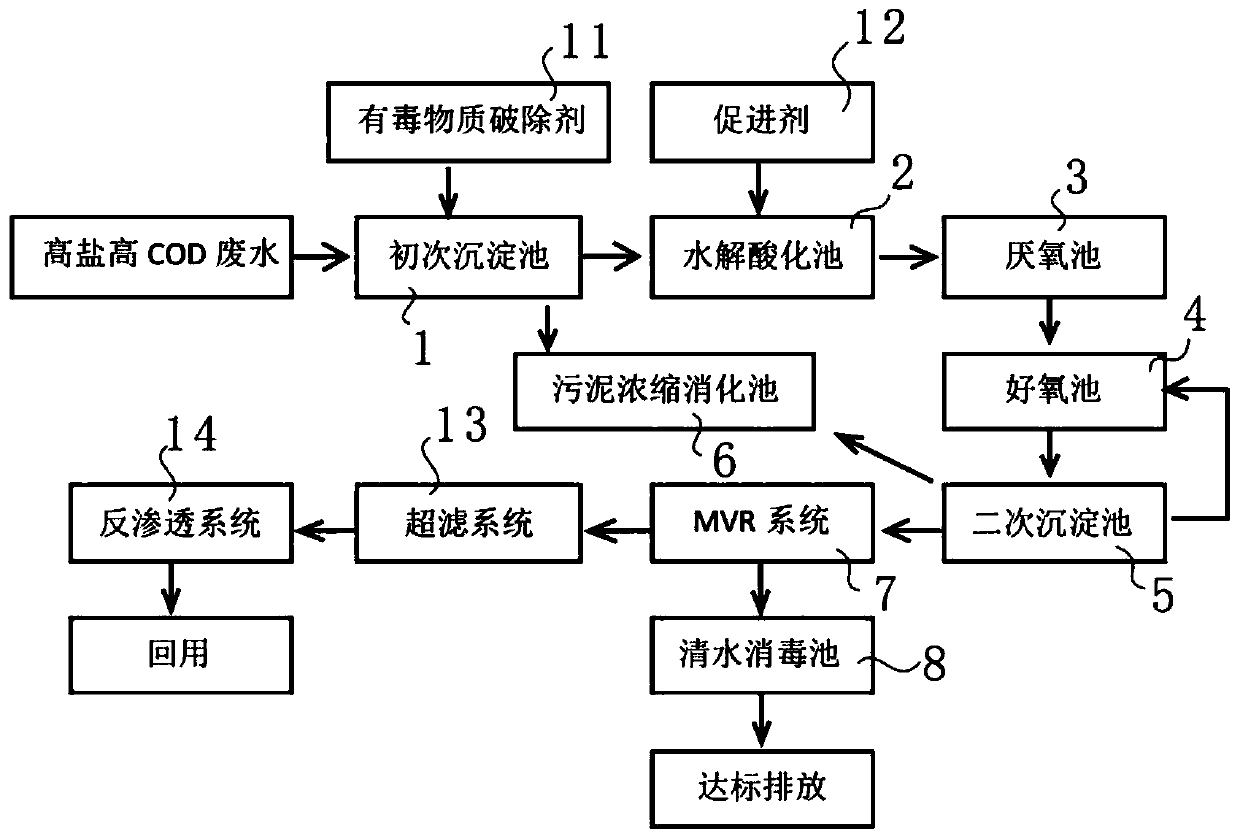

[0021] As shown in the figure, the present invention provides a treatment system for high-salinity and high-COD industrial wastewater, which adopts a combined treatment process of physical and chemical pretreatment, biochemical treatment and physical treatment, and includes the initial precipitation in sequence according to the flow direction of the wastewater Pool 1, hydrolytic acidification pool 2, anaerobic pool 3, aerobic pool 4, secondary sedimentation pool 5, sludge concentration digestion pool 6, MVR system 7 and water disinfection pool 8, among which,

[0022] The primary sedimentation tank 1 is equipped with a dosing device for adding toxic substance removal agent 11. The toxic substance removal agent 11 has the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt tolerance | aaaaa | aaaaa |

| salt tolerance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com