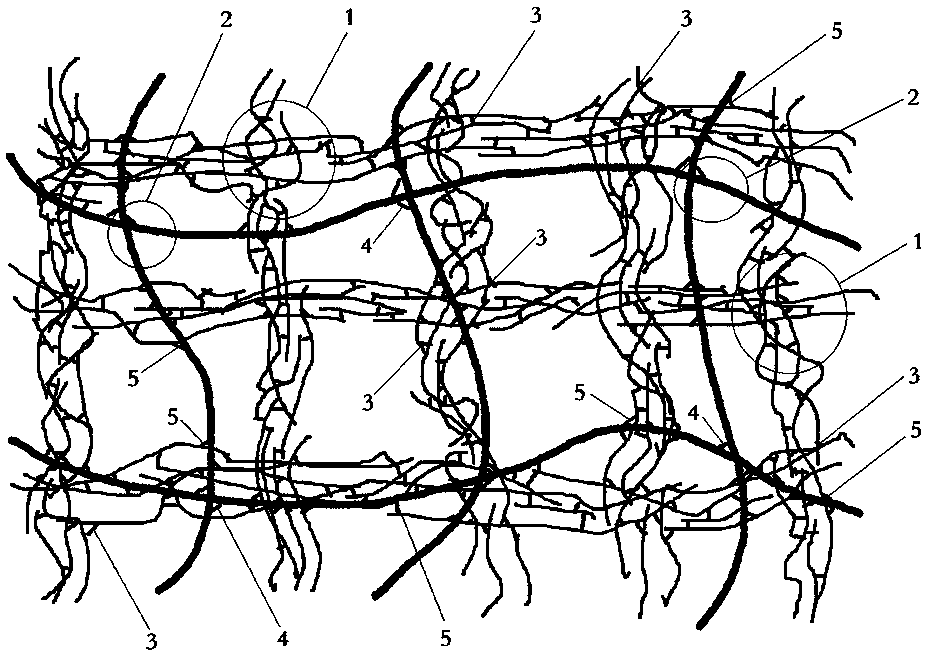

Silk fibroin-sodium hyaluronate cross-linked dual-network gel and preparation method thereof

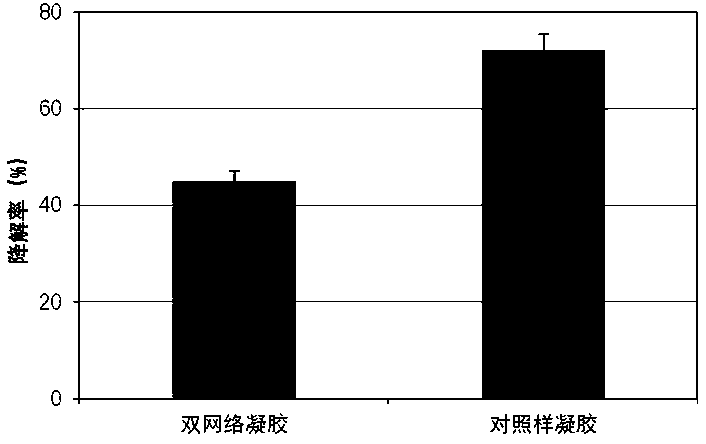

A technology of sodium hyaluronate and silk fibroin, which is applied in the field of silk fibroin-sodium hyaluronate cross-linked double network gel and its preparation, can solve the problems of ineffectiveness of the gel, collapse and disintegration of the three-dimensional network, and the like. The effect of strong adhesion, firm network structure and excellent biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

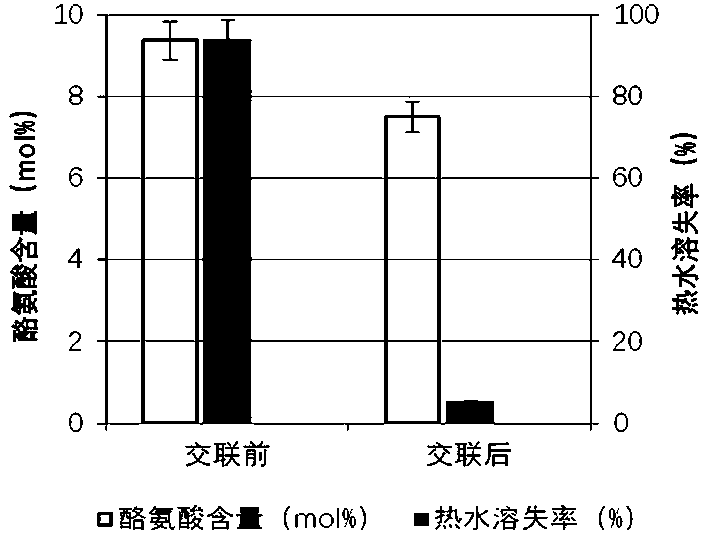

Method used

Image

Examples

Embodiment 1

[0027] After washing, degumming, dissolving and dialysis, the silkworm cocoon shells were diluted with purified water to adjust the concentration to obtain an aqueous silk fibroin protein solution with a concentration of 20 mg / mL.

[0028] Add the 500 U / mL tyrosinase solution and hydrogen peroxide slowly into the silk fibroin protein aqueous solution at 30°C respectively, and stir slowly while adding, every 100 mL of silk fibroin protein solution contains tyrosine The amount of acidase solution added was 15 mL, and that of hydrogen peroxide was 100 μL. The temperature was maintained at 30° C., and the reaction was stirred for 60 minutes to obtain the first component.

[0029] At room temperature, dissolve sodium hyaluronate with an average molecular weight of 1000 kDa in 50 mmol / L 2-morpholineethanesulfonic acid (MES) solution, and stir slowly while dissolving to make the sodium hyaluronate in the solution The concentration is 8 mg / mL, and N-hydroxysuccinimide (NHS) and 1-(3-...

Embodiment 2

[0041] After the silkworm raw silk was degummed, dissolved, and dialyzed, it was diluted with purified water to adjust the concentration to obtain an aqueous silk fibroin protein solution with a concentration of 2 mg / mL.

[0042] At room temperature, dissolve tyrosinase in purified water, stir slowly while dissolving, and prepare a tyrosinase solution with a concentration of 500 U / mL.

[0043] Add the tyrosinase solution and hydrogen peroxide dropwise to the silk fibroin protein aqueous solution at a temperature of 15°C, and stir slowly while adding the solution. The amount of the tyrosinase solution added per 100 mL silk fibroin protein solution is 25 mL, the dropwise volume of hydrogen peroxide is 450 μL. The temperature was maintained at 15°C and the reaction was stirred for 180 minutes. Get the first component.

[0044] At room temperature, dissolve sodium hyaluronate with an average molecular weight of 2000 kDa in 50 mmol / L MES solution, stir slowly while dissolving, so...

Embodiment 3

[0048] After the silkworm raw silk was degummed, dissolved, and dialyzed, it was diluted with purified water to adjust the concentration to obtain an aqueous silk fibroin protein solution with a concentration of 38 mg / mL.

[0049] Add the 500 U / mL tyrosinase solution and hydrogen peroxide slowly into the silk fibroin protein aqueous solution at a temperature of 50 °C respectively, and stir slowly while adding, every 100 mL of silk fibroin protein solution contains The dropping volume of acidase solution was 2 mL, and the dropping volume of hydrogen peroxide was 15 μL. The temperature was maintained at 50°C and the reaction was stirred for 120 minutes. Get the first component.

[0050] At room temperature, dissolve sodium hyaluronate with an average molecular weight of 400 kDa in 50 mmol / L MES solution, stir slowly while dissolving, so that the concentration of sodium hyaluronate in the solution is 20 mg / mL, and then NHS and EDC solutions were added dropwise into the solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com