Acrylic special-shaped panel and manufacturing method thereof

A manufacturing method and acrylic technology, applied in the field of acrylic special-shaped panel and its manufacturing, can solve the problems of installation failure, glue line, hard cannot be modified or bent, etc., to achieve good workability, eliminate glue line, and eliminate the effect of color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The acrylic special-shaped panel is made of the following raw materials by weight percentage: A material 95%, B material 4%, C material 1%; among them, A material is made of the following components by weight percentage: MMA 25%, PMMA 15%, 20% of monofunctional acrylic ester monomer with atmospheric boiling point greater than 115°C, 35% of aluminum hydroxide with a mesh number of 70-3000 mesh, 3% of color paste, 1% of organometallic salt accelerator, and 2% of defoamer; B Material is peroxide curing agent; material C is EGDMA.

[0036] The manufacturing method of embodiment 1 comprises the following steps:

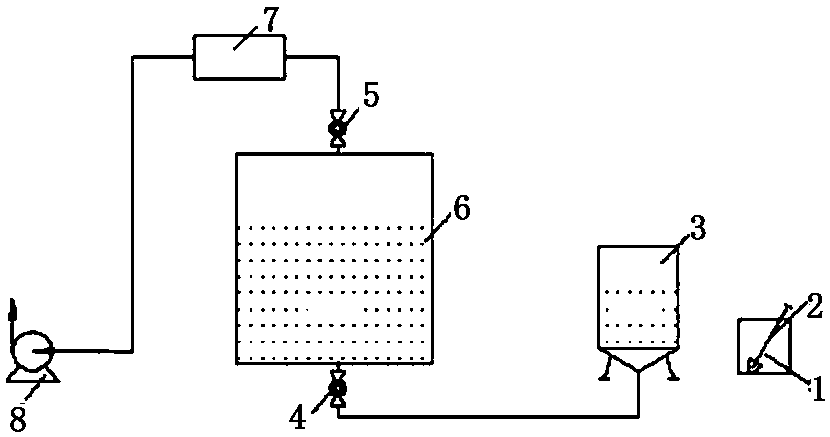

[0037] S1. Complete the closed mold cavity 6 on site according to the design requirements, set a vacuum exhaust pipe at the top of the mold cavity 6, and set a feed pipe at the bottom of the mold cavity 6;

[0038] S2. Connect the vacuum pumping pipe to the vacuum pump 8 through the plastic barrel 7, connect the feeding pipe to the feeding barrel 3, install a detac...

Embodiment 2

[0046] The acrylic special-shaped panel is made of the following raw materials by weight percentage: A material 93%, B material 5%, C material 2%; among them, A material is made of the following components by weight percentage: PMMA 30%, normal pressure boiling point greater than 37% bifunctional acrylate monomer at 115°C, 25% aluminum hydroxide with a mesh number of 70-3000 mesh, 5% color paste, 2% metal oxide accelerator, and 1% coupling agent; material B is peroxide Material curing agent; C material is benzyl triethyl ammonium chloride.

[0047] The manufacturing method of embodiment 2 comprises the following steps:

[0048] S1. Make a closed mold cavity on site according to the design requirements, set a vacuum exhaust pipe at the top of the mold cavity, and set a feed pipe at the bottom of the mold cavity;

[0049] S2. Connect the vacuum suction pipe to the vacuum pump through the plastic barrel, connect the feed pipe to the feeding barrel, install a detachable outlet va...

Embodiment 3

[0057] The acrylic special-shaped panel is made of the following raw materials by weight percentage: A material 99.9%, B material 0.1%; among them, A material is made of the following components by weight percentage: MMA 60%, PMMA 5%, and the boiling point at normal pressure is greater than 115 1% polyfunctional acrylate monomer at ℃, 33.8% aluminum hydroxide with a mesh number of 70-3000 mesh, 0.1% hydroxide accelerator, and 0.1% wetting and dispersing agent; material B is a peroxide curing agent.

[0058] The manufacturing method of embodiment 3 comprises the following steps:

[0059] S1. Make a closed mold cavity on site according to the design requirements, set a vacuum exhaust pipe at the top of the mold cavity, and set a feed pipe at the bottom of the mold cavity;

[0060] S2. Connect the vacuum suction pipe to the vacuum pump through the plastic barrel, connect the feed pipe to the feeding barrel, install a detachable outlet valve on the vacuum suction pipe, and install...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com