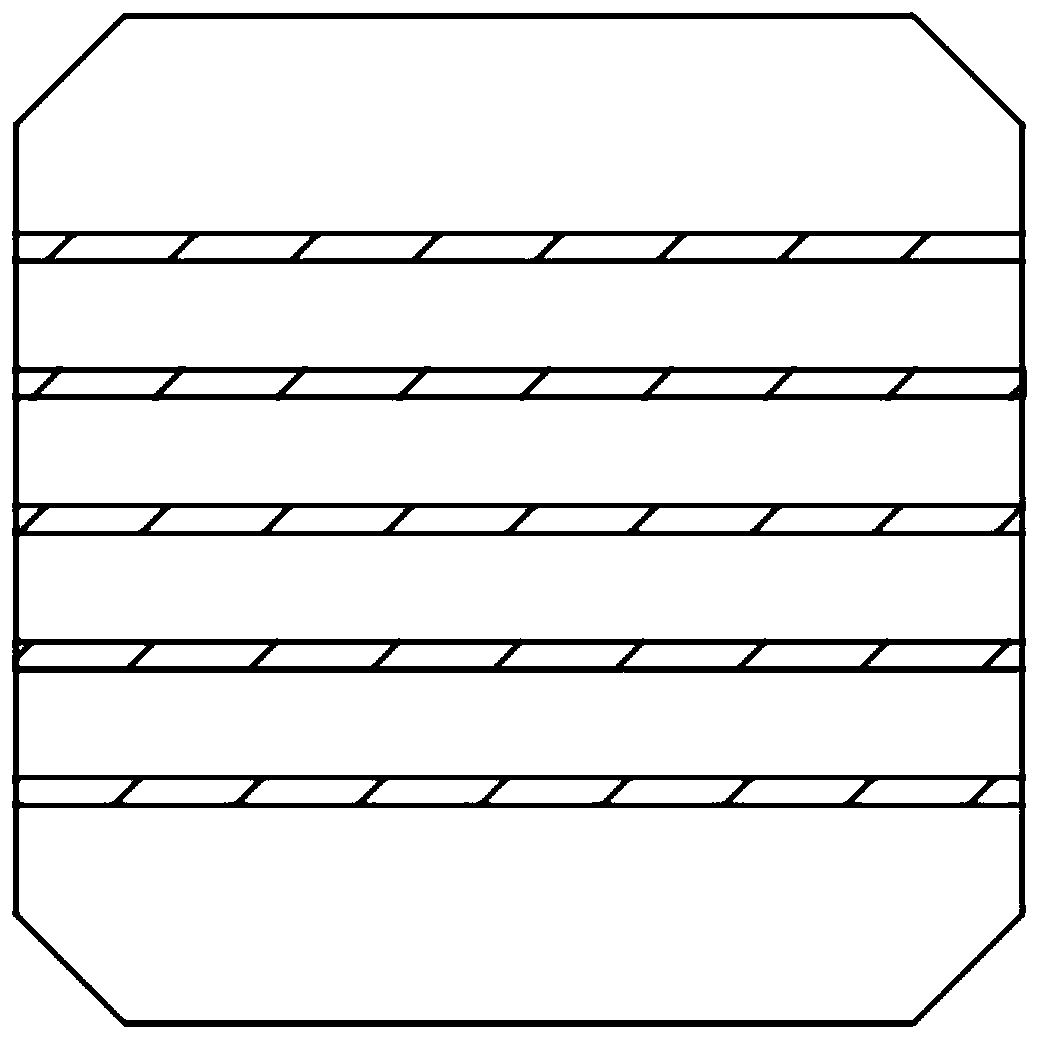

UV curing adhesive glue, solar reflective strip and solar reflective strip seamless film connecting production process

A production process and solar energy technology, applied in the field of solar cells, can solve problems such as low production yield, high repair rate, and appearance differences, and achieve good weather resistance, strong mechanical strength, and yield improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

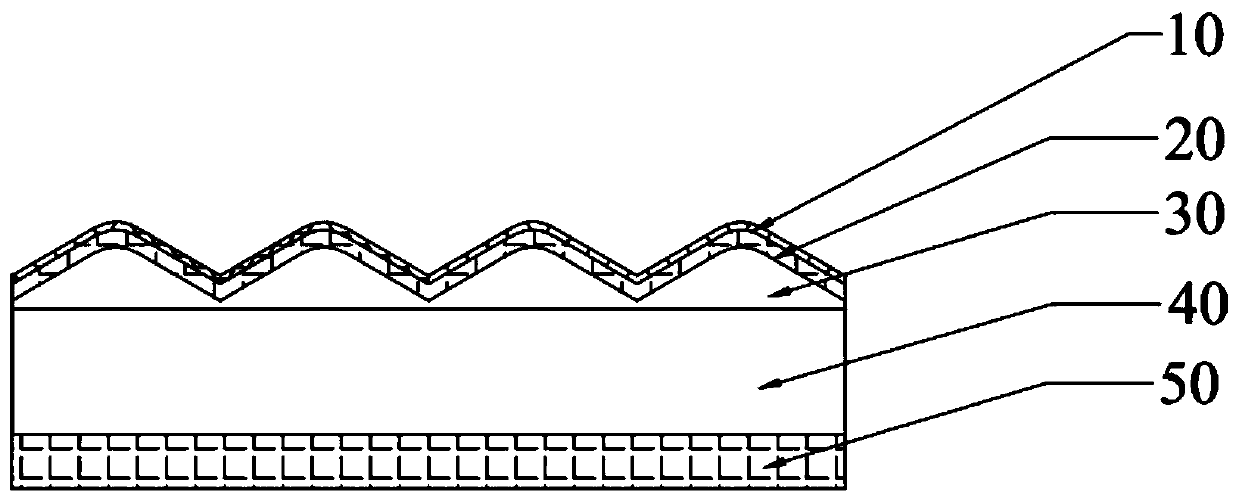

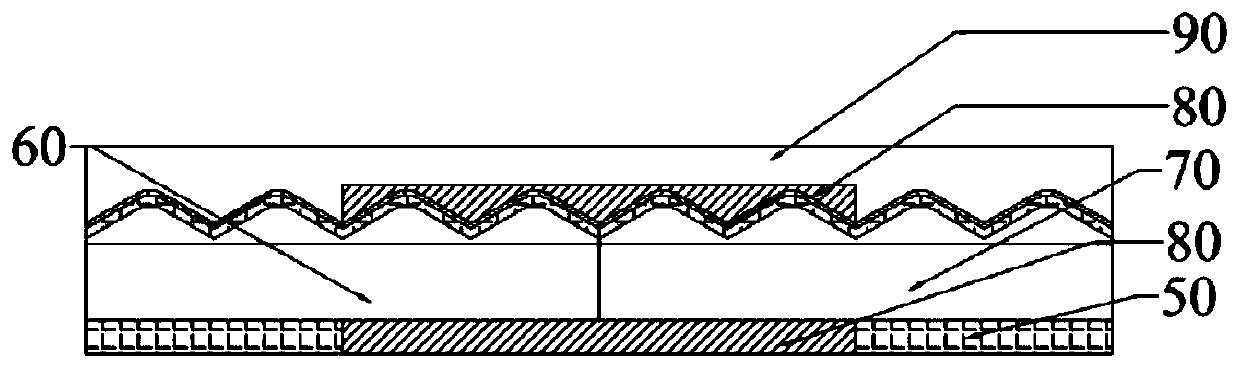

Embodiment 1

[0070] The UV curing adhesive provided by the present invention (abbreviated as UV adhesive) comprises the following components: 52 parts of carboxyl-free urethane acrylate oligomer, its molecular weight is 35000~40000, and the glass transition temperature Tg is -26 ℃, 42 parts of carboxyl-free monofunctional acrylate monomer, 1 part of acrylate leveling agent, and 5 parts of TPO photoinitiator. The components are mixed together to obtain the UV curable adhesive. Among them, the carboxyl-free urethane acrylate oligomer and the carboxyl-free monofunctional acrylate monomer were provided by Changxing Materials Industry Co., Ltd., the leveling agent was provided by BYK Company of the United States, and the photoinitiator was provided by BASF. The above-mentioned UV curing adhesive is coated on the UV-1 adhesive tape (transparent adhesive tape), and attached to the substrate layer of the joint part of the solar reflective strip (such as Figure 4 Shown), carry out ultraviolet lig...

Embodiment 2

[0073] The UV curing adhesive provided by the present invention includes the following components: 57 parts of carboxyl-free urethane acrylate oligomer with a molecular weight of 30,000 to 35,000, a glass transition temperature Tg of -24°C, and 38 parts of carboxyl-free Monofunctional acrylate monomer, 0.8 parts of acrylate leveling agent, and 4.2 parts of TPO photoinitiator are mixed together. Among them, the carboxyl-free urethane acrylate oligomer and the carboxyl-free monofunctional acrylate monomer were provided by Changxing Materials Industry Co., Ltd., the leveling agent was provided by BYK Company of the United States, and the photoinitiator was provided by BASF. Apply the above UV-curable adhesive to the UV-1 tape, attach it to the joint part of the solar reflective strip, perform ultraviolet curing, and divide into strips normally to obtain 1.2mm strips of the solar reflective strip.

[0074] Among them, the thickness of the joint part of the solar reflective strip i...

Embodiment 3

[0076]The UV curing adhesive provided by the present invention includes the following components: 55 parts of carboxyl-free urethane acrylate oligomer with a molecular weight of 30,000 to 35,000, a glass transition temperature Tg of -24°C, and 40 parts of carboxyl-free Monofunctional acrylate monomer, 0.5 parts of acrylate leveling agent, and 4.5 parts of TPO photoinitiator are mixed together. Among them, the carboxyl-free urethane acrylate oligomer and the carboxyl-free monofunctional acrylate monomer were provided by Changxing Materials Industry Co., Ltd., the leveling agent was provided by BYK Company of the United States, and the photoinitiator was provided by BASF. Apply the above UV-curable adhesive to the UV-1 tape, attach it to the joint part of the solar reflective strip, perform ultraviolet curing, and divide into strips normally to obtain 1.2mm strips of the solar reflective strip.

[0077] Among them, the thickness of the joint part of the solar reflective strip is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com