High-thermal-stability high-strength Re-free nickel-based single-crystal high-temperature alloy and preparation process thereof

A high thermal stability, nickel-based single crystal technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of low strength, high cost, poor stability, etc., achieve high temperature strength, good thermal corrosion resistance , the effect of high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0042] See Table 1 for the chemical composition of the nickel-based single crystal superalloy in Examples 1-6 of the present invention.

[0043] Table 1 The chemical composition list (wt.%) of the alloy of the present invention (embodiment 1-6)

[0044] alloy Cr co W Al Ti Ta Mo Re Ni Example 1 7.8 8.0 8.0 5.2 1.56 5.5 1.8 0 Remain Example 2 7.8 8.5 8.0 6.5 2.0 8.5 1.8 0 Remain Example 3 9.1 10.0 9.2 5.5 1.45 5.5 2.5 0 Remain Example 4 9.2 10.2 9.0 6.3 2.3 8.5 2.5 0 Remain Example 5 8 10.5 8.5 6 2.0 8.5 2.2 0 Remain Example 6 8.5 11 8.5 5 1.5 8.0 2 0 Remain Rene N5 7.0 7.5 5.0 6.2 0 6.5 1.5 3 Remain

[0045] Performance test is carried out to alloy in above embodiment, and result is as follows:

[0046] 1. The measured density of the alloy in Example 6 is 8.57g / cm 3 .

Embodiment 5

[0048] Table 2 Example 5 alloy durability

[0049] temperature / degree Stress / MPa Durable life / h Elongation / % 1093 137 190 7 1038 172 280 13 1010 235 108 21 1100 190 153 14 980 250 210 14 800 750 281 15

[0050] 3. The durability performance data of the alloy of Example 6 of the present invention and the comparative alloy Rene N5 under several test conditions are shown in Table 3.

[0051] Table 3 The durability performance of embodiment 6 alloy and contrast alloy Rene N5

[0052]

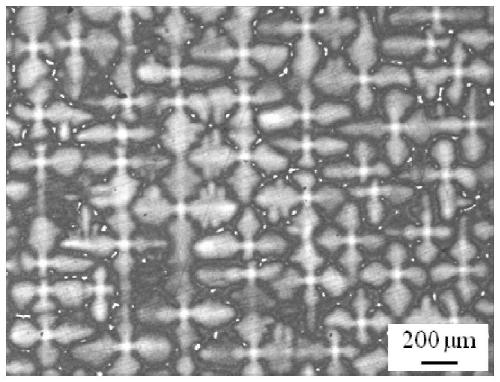

[0053] 4. The as-cast microstructure of the alloy in Example 1 of the present invention is as follows: figure 1 shown.

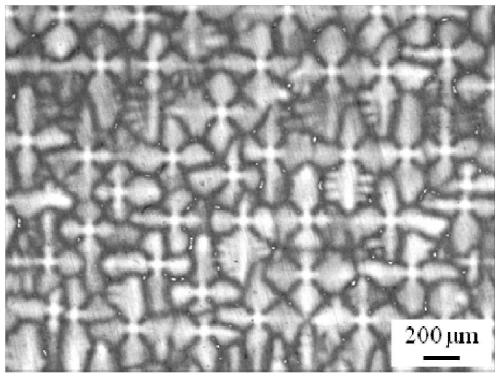

[0054] 5. The as-cast microstructure of the alloy of Example 2 of the present invention figure 2 shown.

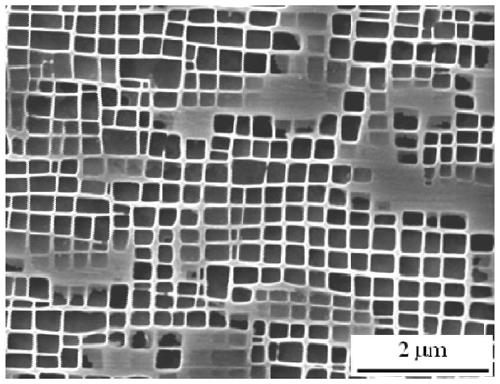

[0055] 6. The microstructure of the alloy in Example 3 of the present invention after heat treatment is as follows: image 3 shown.

[0056] 7. Microstructure of the alloy in Example 4 of the present inven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com