A low flow resistance chip embedded array microfluidic radiator and its manufacturing method

An embedded and micro-fluidic technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problems of high flow resistance, large pressure drop, easy wear, etc., achieve high heat transfer efficiency, reduce The effect of pump power consumption, low flow resistance and high efficiency heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

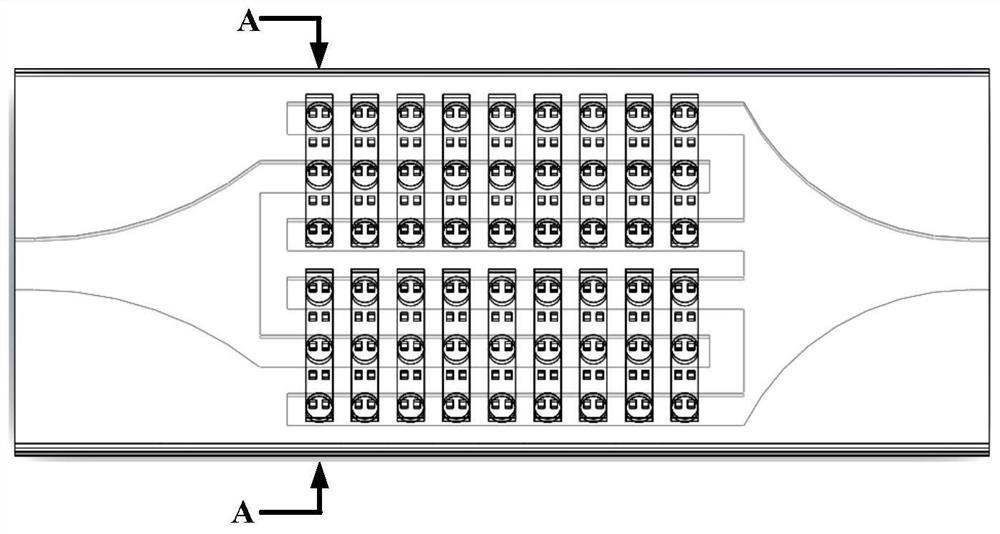

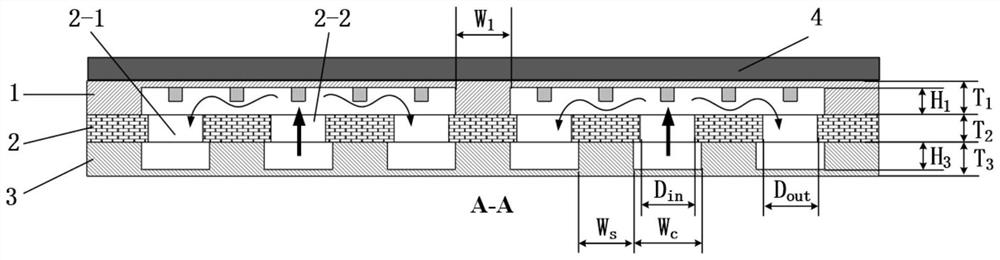

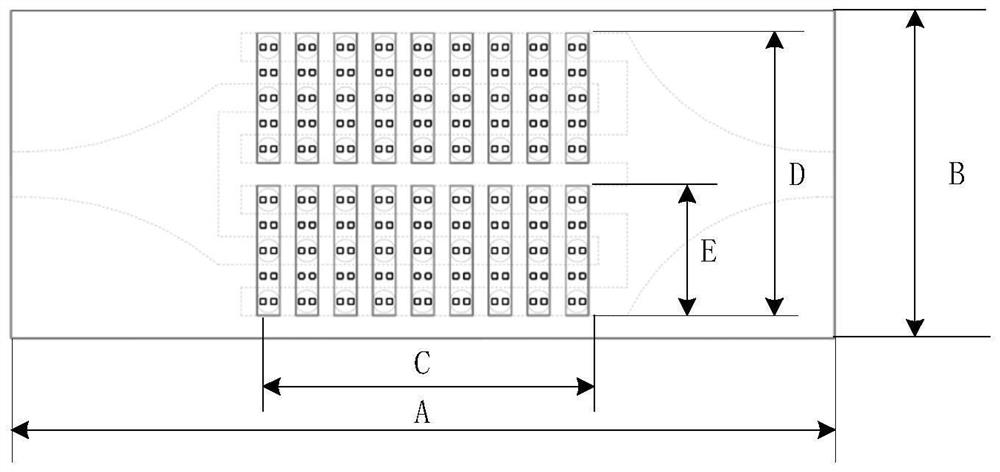

[0034] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0035] In order to reduce the flow pressure drop of the array micro-jet heat dissipation technology and improve the safety and reliability of the device, the present invention starts from two aspects: the optimization of the jet channel structure and the enhancement of the micro-jet heat transfer process. The excellent heat transfer capability of micro-fluidic technology stems from the high degree of synergy between the fluid velocity field gradient and the temperature field gradient of the wall (the included angle is close to 0 degrees). The impact of the fluid on the wall surface forms a strong disturbance in the thermal boundary layer, effectively reducing the thermal resistance. Increasing the fluid inertia (flow velocity) can enhance the disturbance effect and achieve the purpose of enhancing heat transfer, but the flow pressure drop also increases sharply. Elast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com