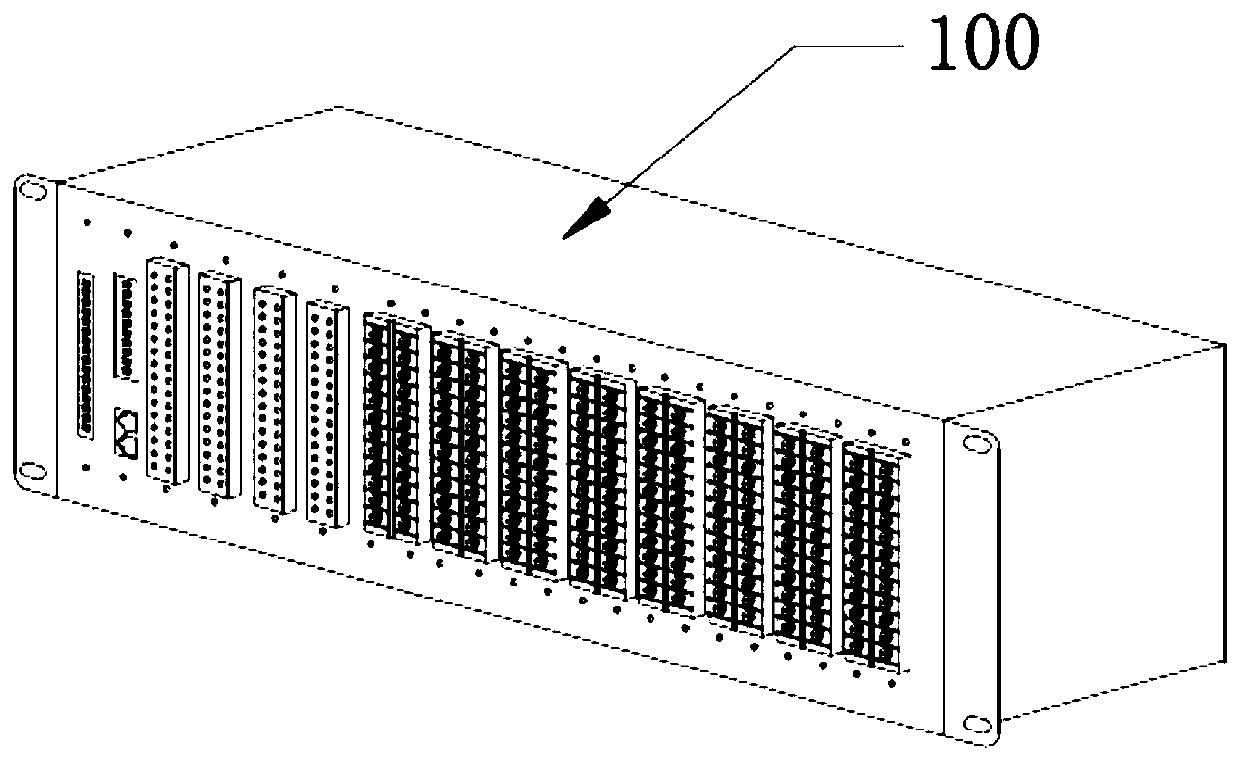

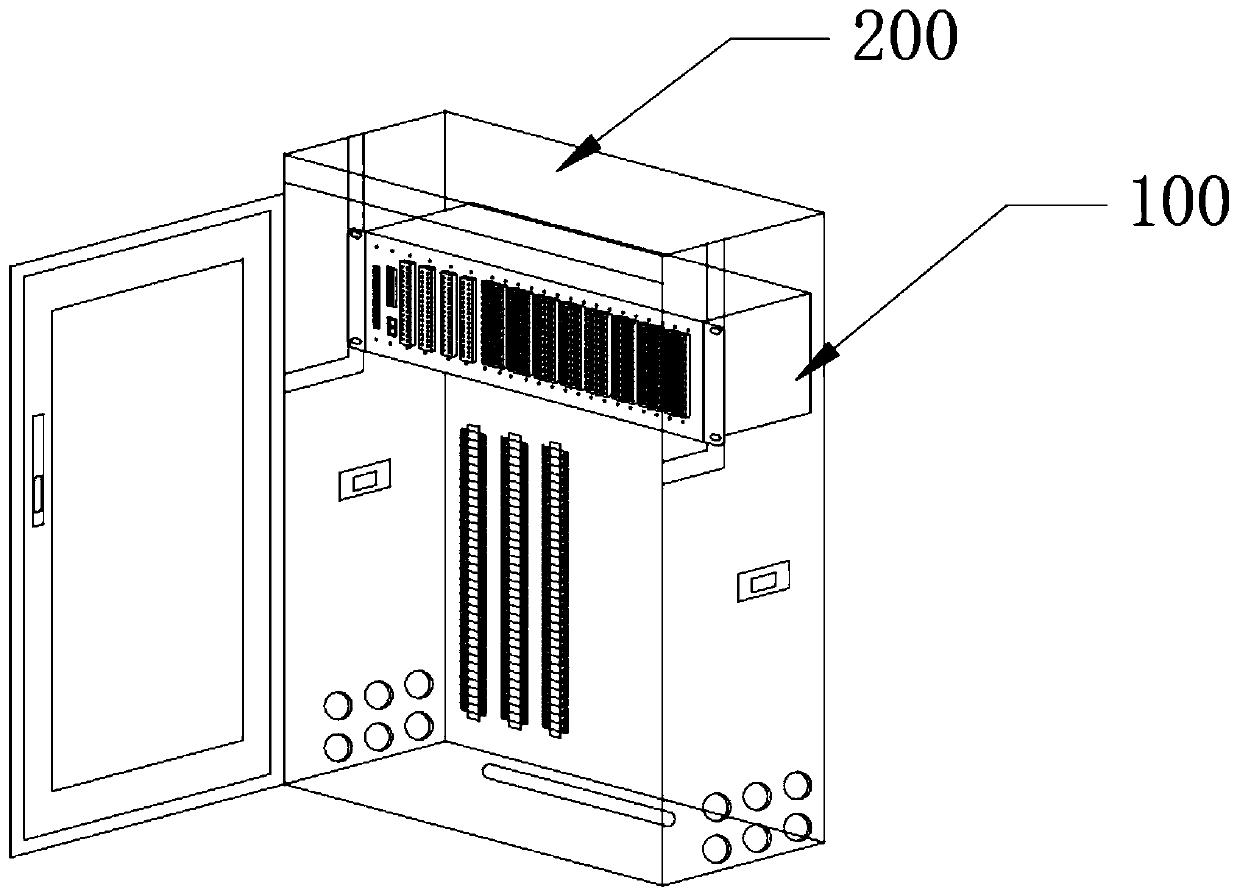

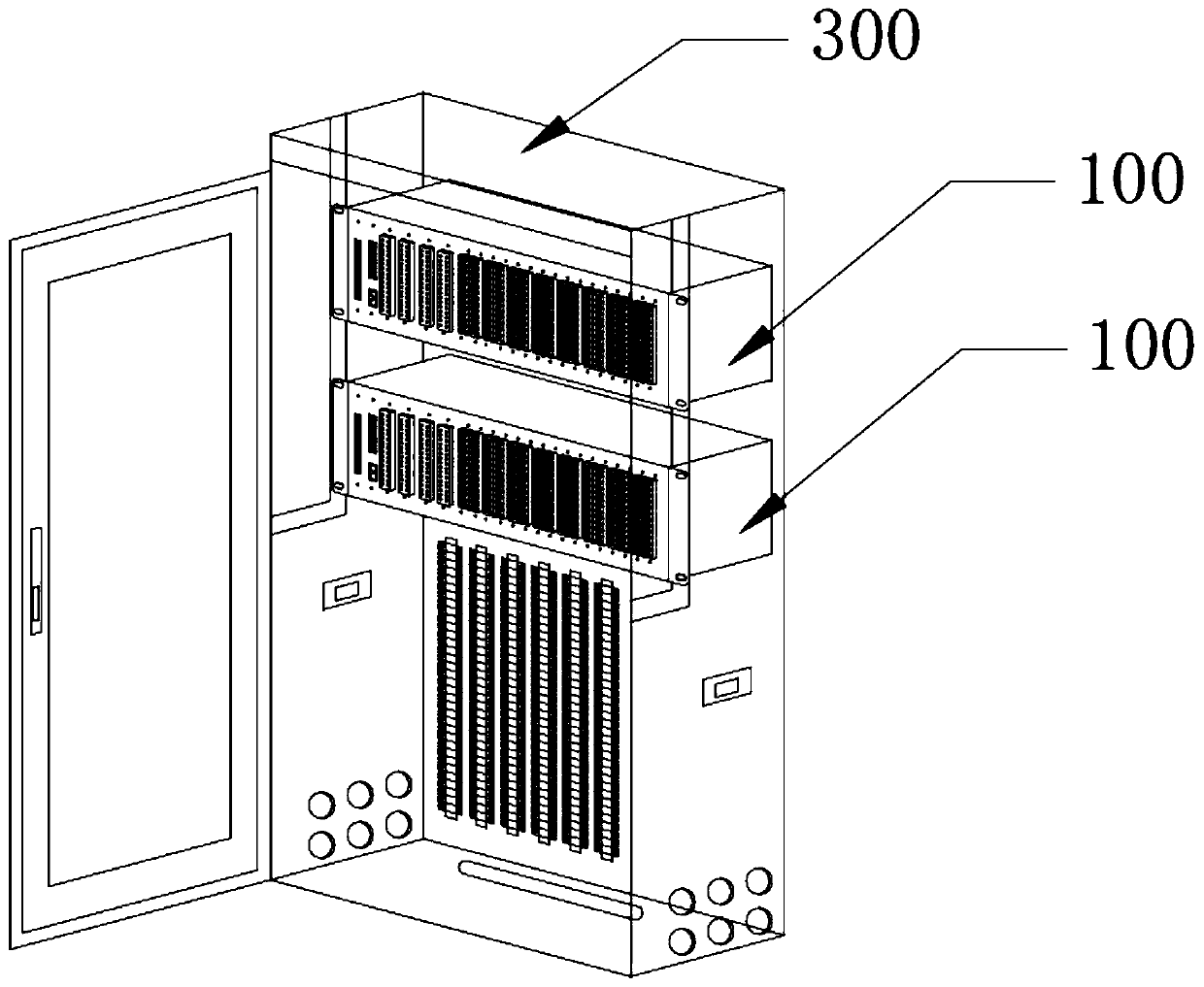

Wiring-free centralized control type distribution automation terminal and system thereof

A power distribution automation and centralized control technology, applied in information technology support systems, electrical components, circuit devices, etc., can solve the problem of inability to remotely modify or upgrade the system online, increase the labor intensity of operation and maintenance personnel, and increase the probability of wrong wiring and other problems, to achieve the effect of simple structure, fast fault diagnosis and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] An embodiment of a wiring-free centralized control distribution automation terminal:

[0036] see Figure 4 to Figure 10 , the wiring-free centralized control type power distribution automation terminal of the present invention is installed in the power distribution equipment, including a first power supply module, a first anti-surge protection module 15, a first EMC filter module 16, and a first central processing unit 17 , a terminal central processing unit 60 composed of the first Ethernet module 18 and a WIFI module 23, and a plurality of power distribution terminal subunits 50, the plurality of power distribution terminal subunits 50 are used to collect electrical signals of power distribution equipment, and the terminal central processing unit 60 communicates with multiple power distribution terminal subunits 50 through the WIFI module 23 . Wherein, the first power module includes a mains power access terminal and a power conversion module 14 .

[0037] Wherein,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com