Extruded 3D printing coated sustained-release preparation and preparation method thereof

A slow-release preparation and 3D printing technology, applied in the field of medicine and medicine, can solve problems such as unstable production process, inability to quickly deposit, and poor print strength, and achieve stable and efficient production, no obvious changes in appearance and sustained release, extrusion Good printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Preparation and Evaluation of Diclofenac Sodium Sustained Release Preparation

[0030] Weigh 4.5g of gelatin, 0.9g of glycerin and 9.6g of water, and place them in a water bath at 55°C to fully mix and swell. Add 6.4g of diclofenac sodium and mix well to prepare the inner core material. Weigh 4.5g of gelatin, 0.9g of glycerin and 9.6g of water, and place them in a water bath at 55°C to fully mix and swell. Add 5g of HPMC K4M and mix evenly to prepare the coating material. Add the above materials into the barrel of the extrusion printer.

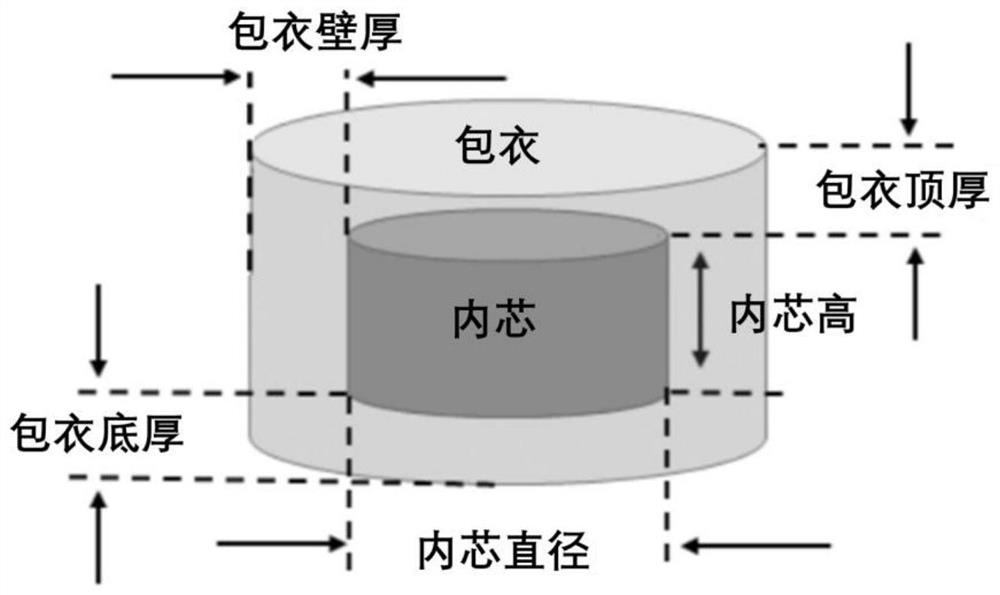

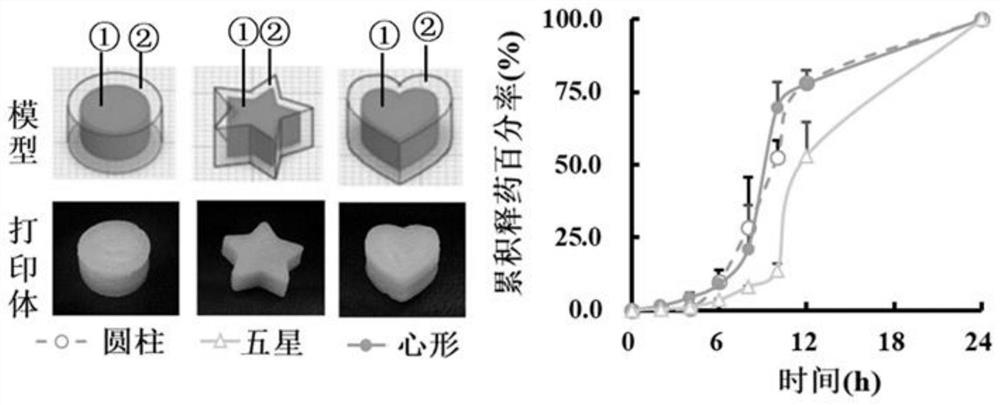

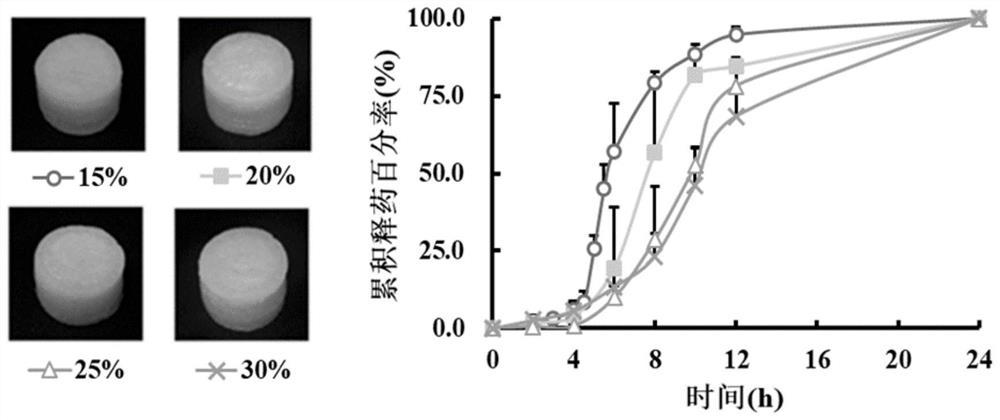

[0031] A cylindrical coated sustained-release preparation model was established, with an inner core diameter of 8.8 mm, a height of 4.5 mm, a coating wall thickness of 1.6 mm, a bottom thickness of 2.0 mm, and a top thickness of 2.0 mm. Coating printing parameters are: extrusion port diameter 0.8mm, layer height 0.5mm, extrusion temperature 45°C, printing speed 5mm / s, deposition temperature 25°C. Extrude the bottom 4 lay...

Embodiment 2

[0034] Example 2: Preparation and evaluation of different drug-coated sustained-release tablets

[0035]Weigh 3g of gelatin, 0.6g of glycerol and 6.4g of water, and place them in a water bath at 55°C to fully mix and swell. Add different drugs such as 6.8g of aminophylline, 4g of metoprolol tartrate or 1.1g of acetylsalicylic acid and mix them uniformly to prepare the inner core material. Weigh 3g of gelatin, 0.6g of glycerol and 6.4g of water, and place them in a water bath at 55°C to fully mix and swell. Add 3.4g HPMC and mix evenly to prepare coating material. Add the above materials into the barrel of the extrusion printer.

[0036] A cylindrical coated sustained-release preparation model was established, with an inner core diameter of 7.5 mm, a height of 4.5 mm, a coating wall thickness of 1.8 mm, a bottom thickness of 1.8 mm, and a top thickness of 1.8 mm. Coating printing parameters are: extrusion port diameter 0.6mm, layer height 0.3mm, extrusion temperature 45°C, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com