Bionic pre-vascularization material as well as preparation method and application thereof

A biomaterial and leaf vein technology, applied in the field of biomedicine, can solve the problems of long time, insufficient tissue thickness, toxicity, etc., and achieve the effect of improving the survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] A method for preparing a bionic prevascularized material, comprising the following steps:

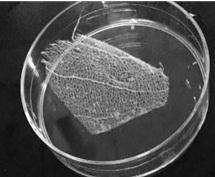

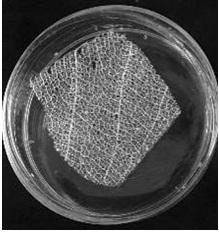

[0079] Step 1. Fabrication of vein structure: Select leaves with reticular veins, which are moderately mature, with light yellow mesophyll and yellowish-brown veins. Put the leaves in 10% sodium hydroxide solution and boil for 10 minutes, wash off the residual sodium hydroxide solution with running water, scrape lightly with tweezers or brush off the mesophyll, and keep the complete leaf vein structure, such as figure 1 shown;

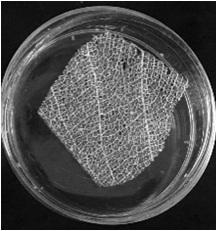

[0080] Place the leaf vein structure in a petri dish or other container, moisten it so that it completely fits the bottom of the container; leaf vein laying method: the back of the leaf vein structure faces up (that is, the back of the leaf faces up), and the other side of the leaf vein structure faces the culture Dish;

[0081] Step 2. PDMS film production: use commercially available Dow Corning SYLGARD™ 184 silicone elastomer and make PDMS according t...

Embodiment 2

[0094] A method for preparing a bionic prevascularized material, comprising the following steps:

[0095] Step 1. Fabrication of vein structure: Select leaves with reticular veins, which are moderately mature, with light yellow mesophyll and yellowish-brown veins. Boil the leaves in water for 5 minutes, wash away the residual solution with running water, gently scrape with tweezers or brush to remove the mesophyll, after cleaning, the leaf veins can be obtained, and the complete leaf vein structure is preserved, and it is ready to use after cleaning;

[0096] Place the vein structure in a petri dish or other container, moisten it so that it is completely attached to the bottom of the container; the method of laying the vein: the back of the vein structure faces upward, and the other side of the vein structure faces the petri dish;

[0097] Step 2. PDMS film production: use commercially available Dow Corning SYLGARD™ 184 silicone elastomer and make PDMS according to its instruc...

Embodiment 3

[0108] A method for preparing a bionic prevascularized material, comprising the following steps:

[0109] Step 1. Place the vein structure purchased in the market in a petri dish or other container, moisten it so that it fits completely with the bottom of the container; the method of laying the vein: the back of the vein structure faces upward, and the other side of the vein structure faces the culture Dish;

[0110] Step 2. PDMS film production Use the commercially available Dow Corning SYLGARD™ 184 silicone elastomer and make PDMS according to its instructions. Mix the silicone and curing agent at a ratio of 12:1. After mixing, centrifuge at 3000rpm / min for 5 minutes; Pour the centrifuged PDMS into a petri dish to cover the leaf veins in step 1, with a thickness of about 0.1mm, and place it on the table, vacuumize to reduce air bubbles; react at 100°C for 8 hours and the PDMS is cured. After returning to room temperature, the veins were removed to obtain a PDMS film with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com