Application of nanorod-shaped CeO2 nanocrystalline catalyst in gas-solid phase crotonaldehyde selective hydrogenation catalytic reaction

A nano-rod-like, selective hydrogenation technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, preparation of organic compounds, etc., can solve the problems of low catalytic selectivity and catalytic stability, etc. problem, to achieve the effect of good catalytic selectivity, good crotyl alcohol selectivity, and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment is a single component nanorod CeO 2 The hydrothermal synthesis method of nanocrystals, by accurately controlling the conditions of hydrothermal synthesis, nanorod-like CeO with uniform shape and size can be obtained 2 Nanocrystalline materials, the specific synthesis method is as follows:

[0032] 1.5-2.5g Ce(NO 3 ) 3 ·6H 2 O crystals were dissolved in 30-50mL ultrapure water, 20-40mL, 0.5-0.6g / mL NaOH aqueous solution was added dropwise to the above solution at room temperature, and the resulting mixture was stirred at room temperature for 20-40 Minutes, then transferred to the hydrothermal reaction kettle, tighten the reaction kettle, keep the temperature at 90-110°C for 15-20h, then naturally cool to room temperature, use ultrapure water to wash several times until it is neutral, and then in 60- Dry in a vacuum oven at 100°C for 15-20h, and finally calcinate the obtained powder in a muffle furnace at 450-550°C for 3-5h to obtain nanorod CeO 2 Nan...

Embodiment 2

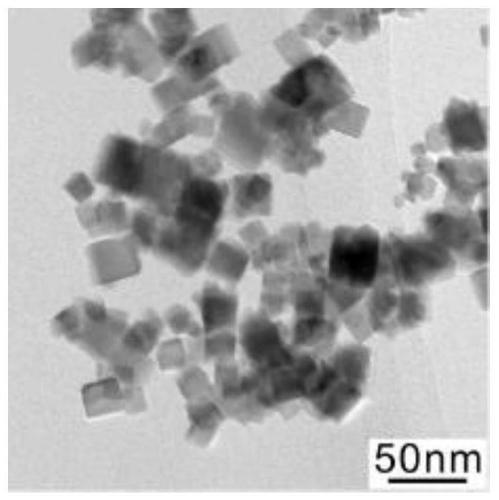

[0035] This embodiment is nano cube CeO 2 Hydrothermal Synthesis of Nanocrystals.

[0036] 1.5-2.5g Ce(NO 3 ) 3 ·6H 2 O crystals were dissolved in 30-50mL ultrapure water, 20-40mL, 0.5-0.6g / mL NaOH aqueous solution was added dropwise to the above solution at room temperature, and the resulting mixture was stirred at room temperature for 20-40 Minutes, then transferred to the hydrothermal reaction kettle, tighten the reaction kettle, keep the temperature at 160-200°C for 15-20h, then naturally cool to room temperature, use ultrapure water to wash several times until it is neutral, and then in 60- Dry in a vacuum oven at 100°C for 15-20h, and finally calcinate the obtained powder in a muffle furnace at 450-550°C for 3-5h to obtain nano-cube CeO 2 Nanocrystalline. To examine its shape, see figure 2 , is the nanocube CeO 2 TEM images of nanocrystals.

Embodiment 3

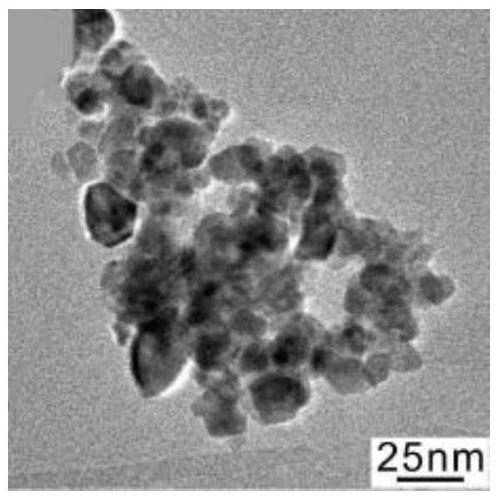

[0038] This embodiment is nano polyhedral CeO 2 Hydrothermal Synthesis of Nanocrystals.

[0039] 1-2g Ce(NO 3 ) 3 ·6H 2 O crystals are placed in a muffle furnace and calcined at 450-550°C for 3-5h to obtain nano-polyhedral CeO 2 Nanocrystalline.

[0040] To examine its shape, see image 3 , image 3 is nanopolyhedral CeO 2 TEM images of nanocrystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com