Steam turbine cold source comprehensive optimization energy-saving device

A technology for energy-saving devices and steam turbines, which is applied in the direction of cleaning heat transfer devices, water shower coolers, and non-rotating equipment cleaning. area, improve heat transfer efficiency, and increase the effect of diffusivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

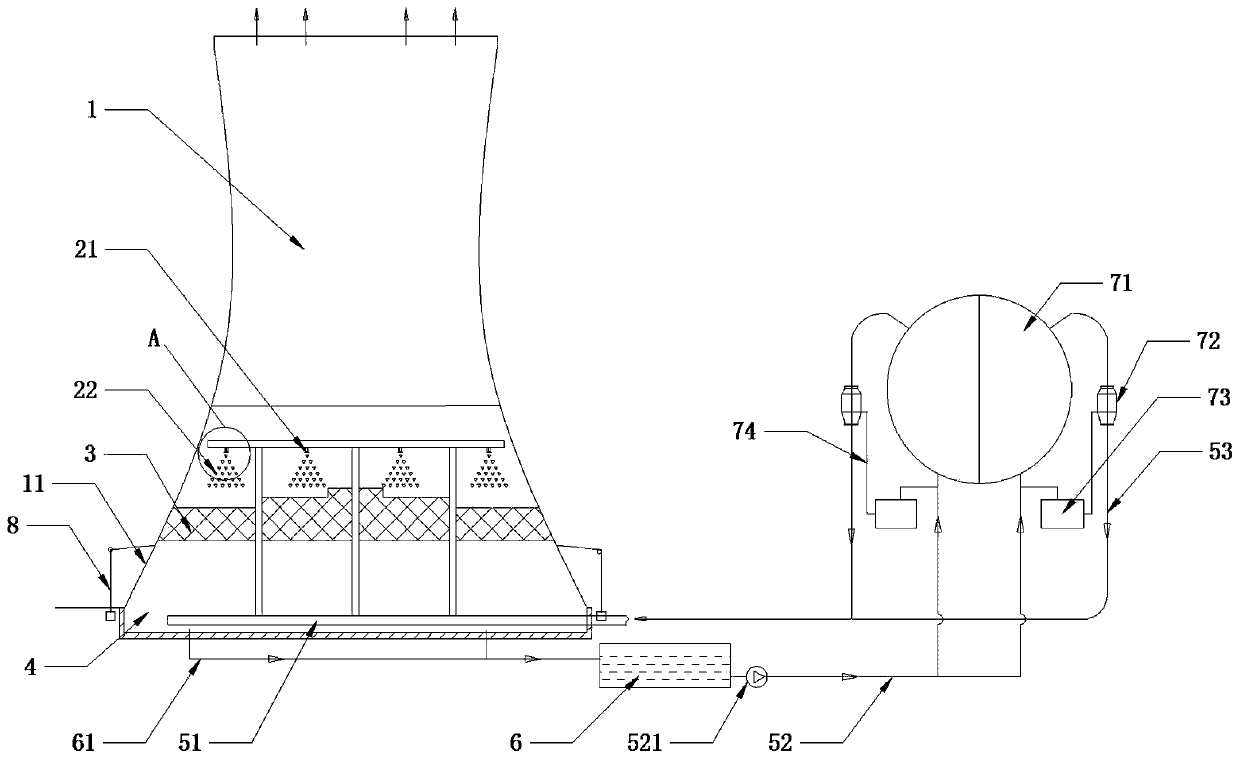

[0040] see Figure 1-8 , a steam turbine cold source comprehensive optimization energy-saving device, including a cooling tower 1, the cooling tower 1 is sequentially provided with a nozzle 2 for increasing the spraying water diffusion area, and fillers for improving the aerodynamic field in the cooling tower 1 3. The sump 4 for water collection, the outer wall of the cooling tower 1 is provided with an air intake regulating device 8 for adjusting the air intake volume of the air inlet 11 of the cooling tower 1 .

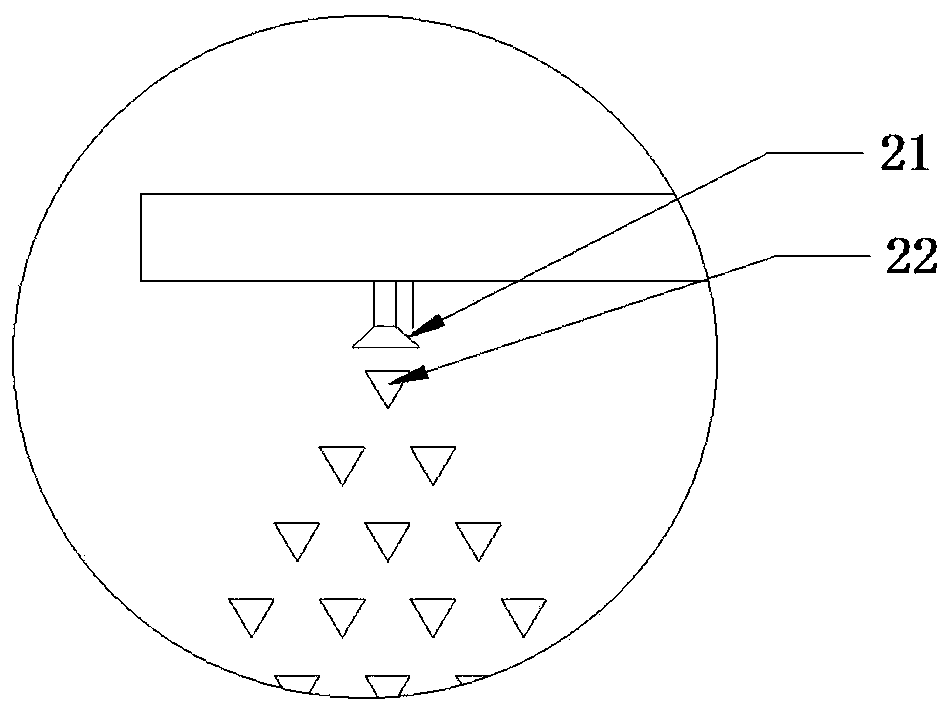

[0041] Preferably, the nozzle 2 includes a nozzle body 21, the nozzle body 21 is provided with a fixing frame 22, and the fixing frame 22 is provided with a splash plate 221 and a splash plate 2 223 sequentially from top to bottom, and the splash plate 221 is provided with A convex platform 222 protruding upwards, and a diversion hole 224 coaxial with the nozzle body 21 is provided in the convex platform 222. The diversion hole 224 runs through the first splash plat...

Embodiment 2

[0050] see Figure 1-8 , based on the above embodiment, the present embodiment provides that the nozzle 2 includes a nozzle body 21, the nozzle body 21 is provided with a fixing frame 22, and the fixing frame 22 is provided with a splash plate 1 221 and a splash plate 2 223 sequentially from top to bottom, The splash plate 221 is provided with an upwardly protruding convex platform 222, and the convex platform 222 is provided with a diversion hole 224 coaxial with the nozzle body 21, and the diversion hole 224 runs through the splash tray 221. The edge of the splash plate 222 and the edge of the first splash plate 221 form a diversion slope 225 , and the second splash plate 223 is arranged below the first splash plate 221 .

[0051] Preferably, the area of the second splash plate 223 is smaller than the area of the first splash plate 221 .

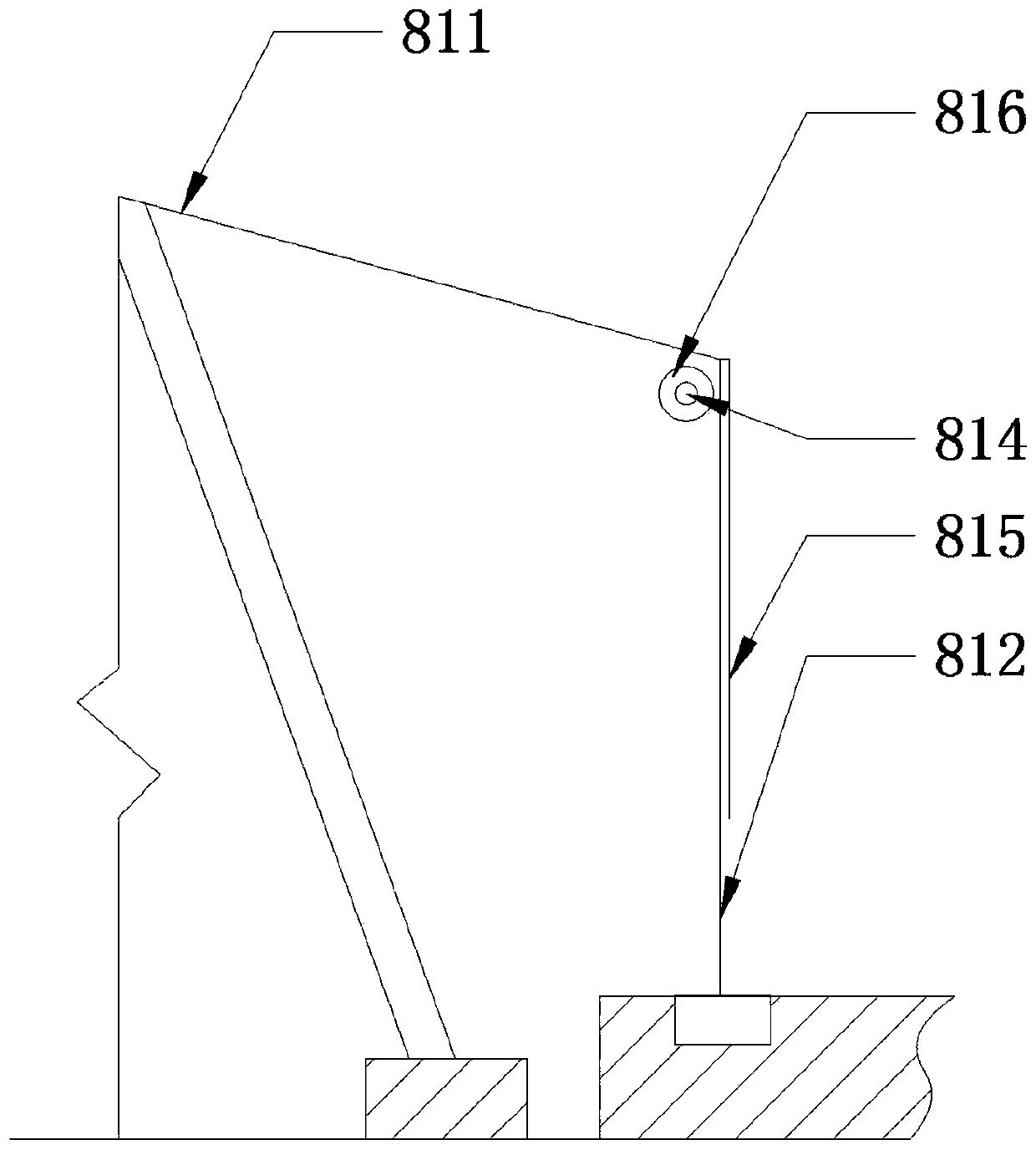

[0052] Preferably, the air intake adjustment device 8 includes a frame 81 erected around the peripheral air inlet 11 of the cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com