A kind of interlayer material and its preparation method and application

A technology of interlayer materials and carbon materials, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of insufficient contact of polysulfides, slow migration of lithium ions, and insufficient conductivity of carbon materials, so as to facilitate ion migration , shorten the lithium ion transmission path, and facilitate the storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] This embodiment provides a method of preparing a sandwich material, comprising the steps of:

[0069] (1) 3.2 mol hexahydrate, 1 mol tetrahydrate mixture ammonium and 6 mol thiourea was dissolved in 80 ml deionized water, and the mixture was stirred at room temperature to clarify to obtain a pink solution;

[0070] (2) 32 mol of 2-methylimidazole was dissolved in 80 mL of deionized water, and the mixture was stirred at room temperature to obtain a solution of 2-methylimidazole.

[0071] (3) Pour the 2-methylimidazole solution obtained by step (2) into the pink solution obtained by step (1), to obtain a deep purple solution, stand for 24 h, to obtain a preform;

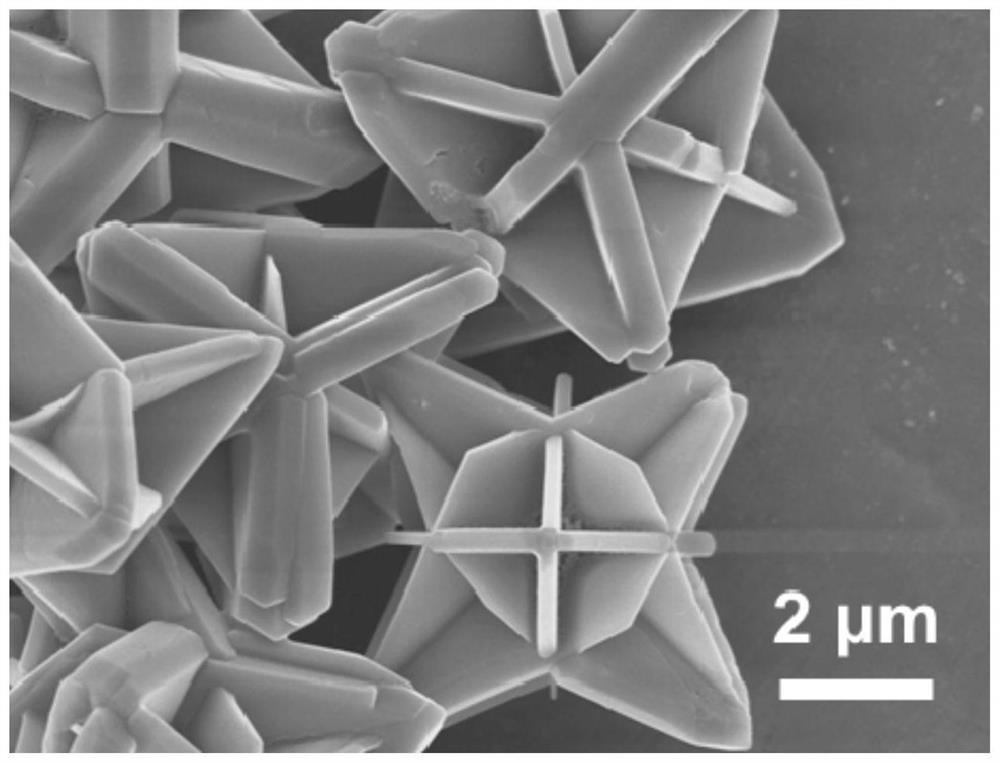

[0072] (4) The prepreg obtained by step (3) was removed to remove the supernatant, and the precipitate obtained was dispersed in ethanol / water mixed solution, filtered, washed four times until the precipitate became blue and purple, Placed at 60 ° C for 12 h in a blast drying tank to obtain a coulcous precursor Mo...

Embodiment 2

[0078] The difference from Example 1 is only that step (1) does not include the addition of thiourea, the remaining compositions, and the preparation method are the same as in Example 1.

[0079] image 3 Scanning electron microscope diagram of the resulting arms-like precursor, from image 3 It can be seen that the product particles obtained are about 4 μm, and the granular morphology is similar to the coar, and the particles are connected, the surface is smooth;

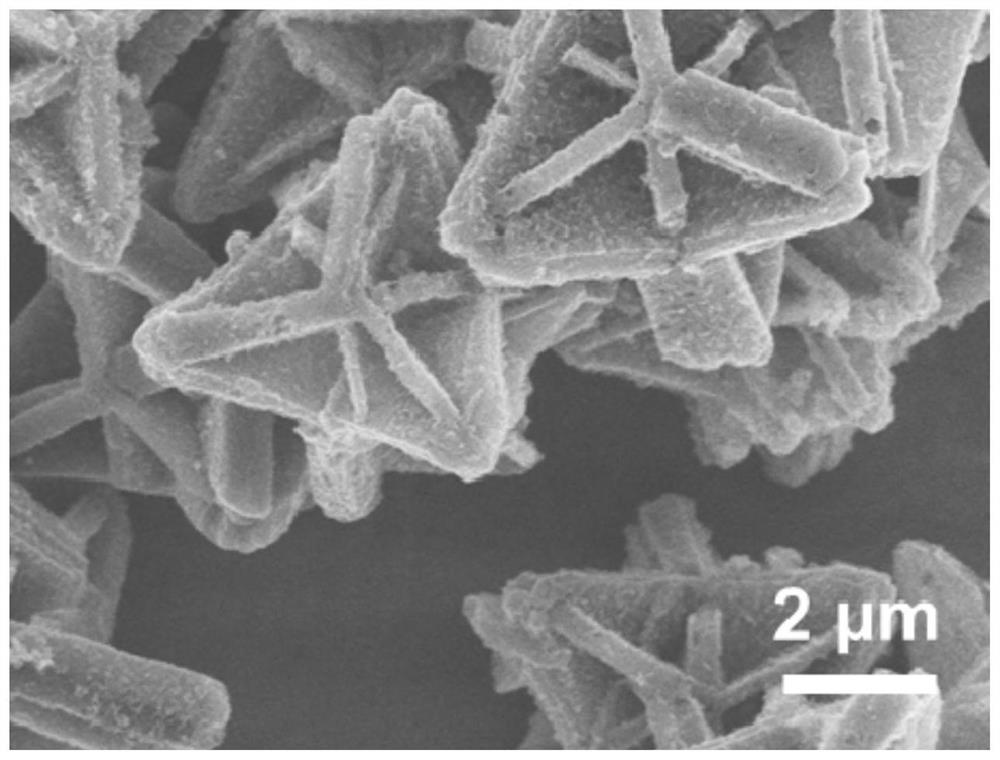

[0080] Figure 4 Scanning electron microscope map for obtained laminated materials, from Figure 4 It can be seen that the product particles obtained are about 4 μm, and the granular morphology is similar to the chopper, and there is a connection between the particles, the surface is rough.

Embodiment 3

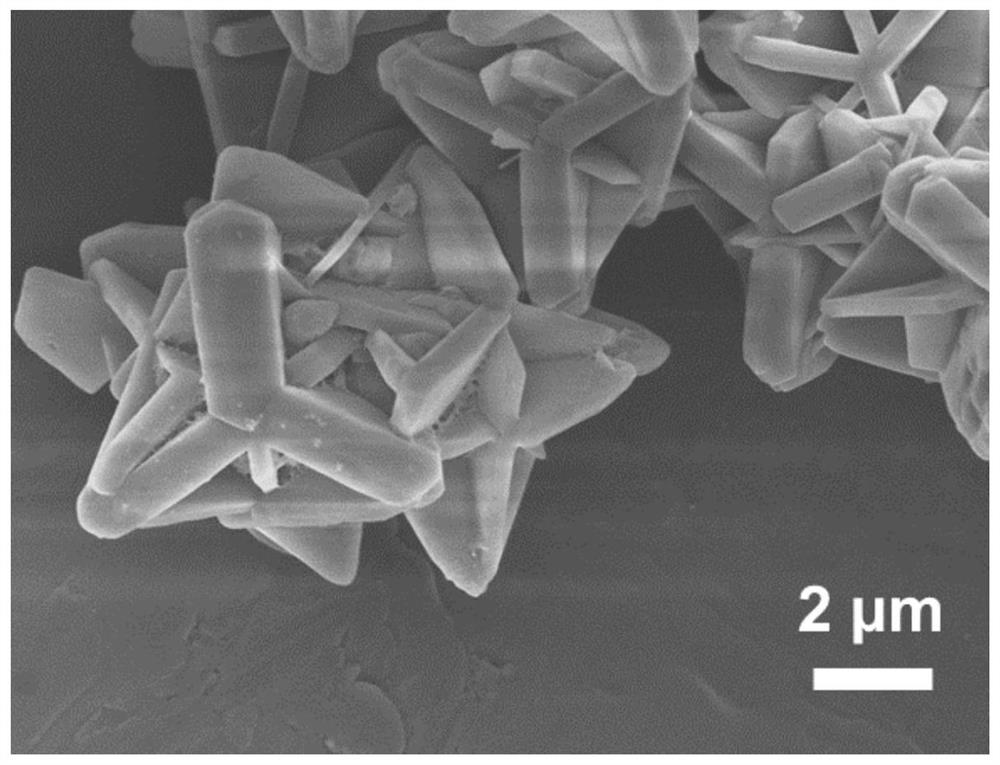

[0082] This embodiment provides a method of preparing a sandwich material, comprising the steps of:

[0083] (1) 4 mmol hexahydrate glycinate, 0.5 mmol tetrahydemolymomide and 10 mmol thiourea were dissolved in 80 ml of deionized water, and the mixture was stirred at room temperature to clarify, to obtain a pink solution;

[0084] (2) 10 mmol of 1-ethylimidazole was dissolved in 80 ml of deionized water, and the mixture was stirred at room temperature to obtain a 1-ethylimidazole solution;

[0085] (3) Pour the 1-ethylimidazole solution obtained by step (2) into the pink solution obtained by step (1), to obtain a deep purple solution, standing for 36 h, to obtain a preform;

[0086] (4) The prepreg obtained by step (3) was removed to remove the supernatant, and the precipitate obtained was dispersed in ethanol / water mixed solution, filtered, washed four times until the precipitate became blue and purple, Placed at 80 ° C for 12 h in a blast drying tank to obtain a predecessor of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com