Methods and apparatus for controlling contaminant deposition on dynode electron-emmissive surface

A technology of dynode and electron emission, applied in the direction of dynode, cleaning method and appliance, electron multiplier dynode, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0089] Example 1: Analysis of Dynode Surfaces Using Auger Electron Microscopy

[0090] The purpose of this study was to identify the main causes of electron multiplier degradation over time with the aim of optimizing detector lifetime in mass spectrometry applications. Understanding the "aging" process in electron multipliers is an essential prerequisite for developing ultra-long-lived mass spectrometer detectors. By studying the dynode surface of ETP multipliers (ETP Electron Multipliers, New South Wales, Australia), the main factors affecting the performance degradation of electron multipliers were identified.

[0091] Although the analysis of dynode surfaces was performed on discrete dynode devices, these results can be generalized to any type of electron multiplier detector.

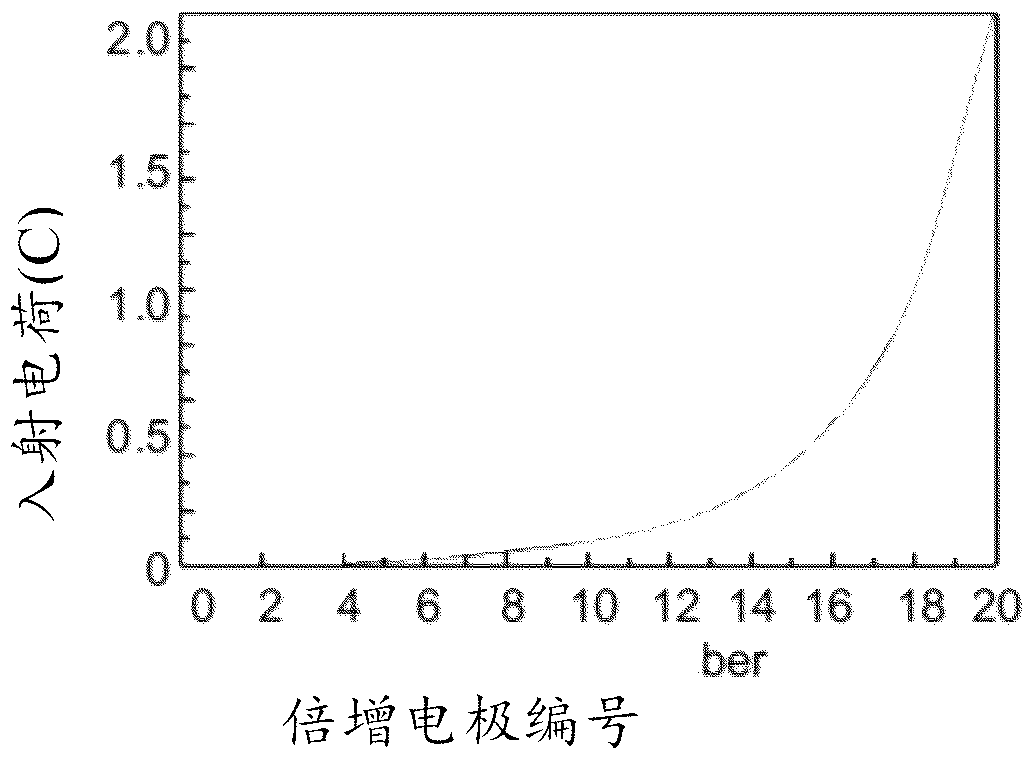

[0092] Tests were performed on a 20-stage multiplier in a 3×10 -6 Operates under millibar vacuum. Introduce a constant flow of nitrogen ions into the multiplier hole and dynamically adjust the m...

example 2

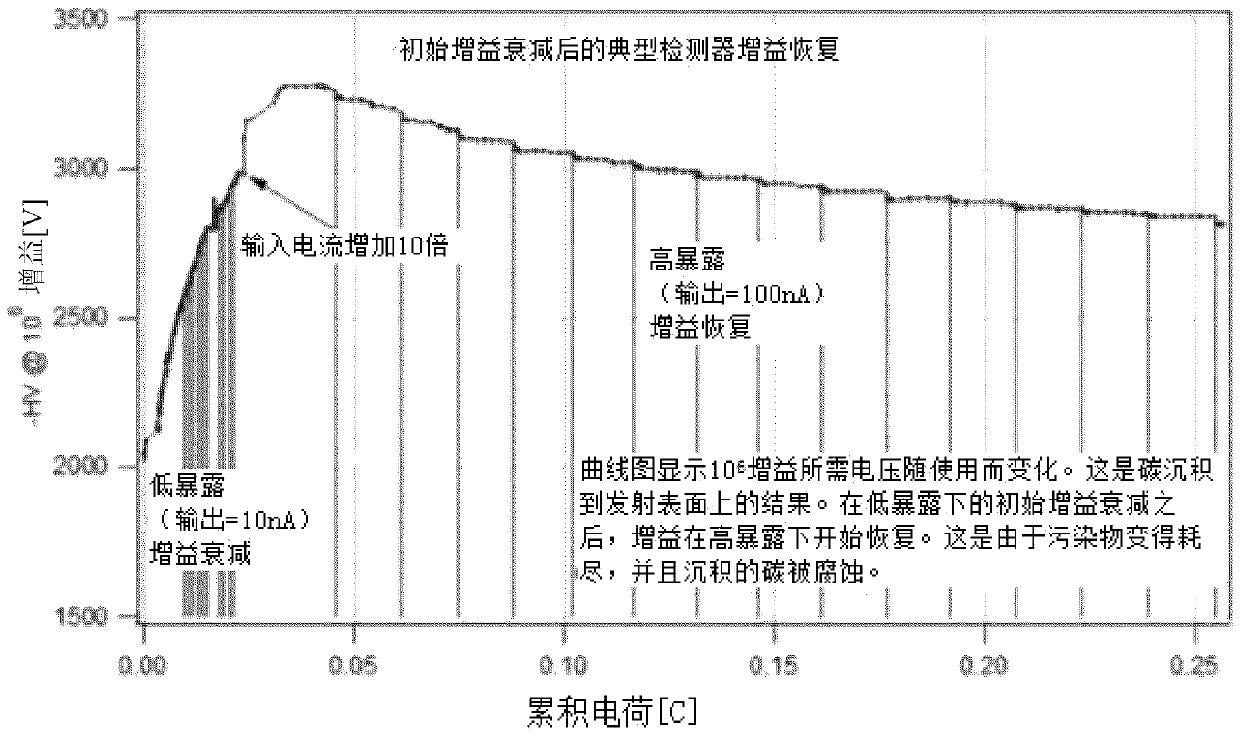

[0100] Example 2: Restoring detector gain after initial gain decay by removing carbonaceous contaminants.

[0101] An experiment was performed to show the removal of carbon deposits from the dynode surface by manipulating the input current in the presence of water molecules. refer to Figure 6 .

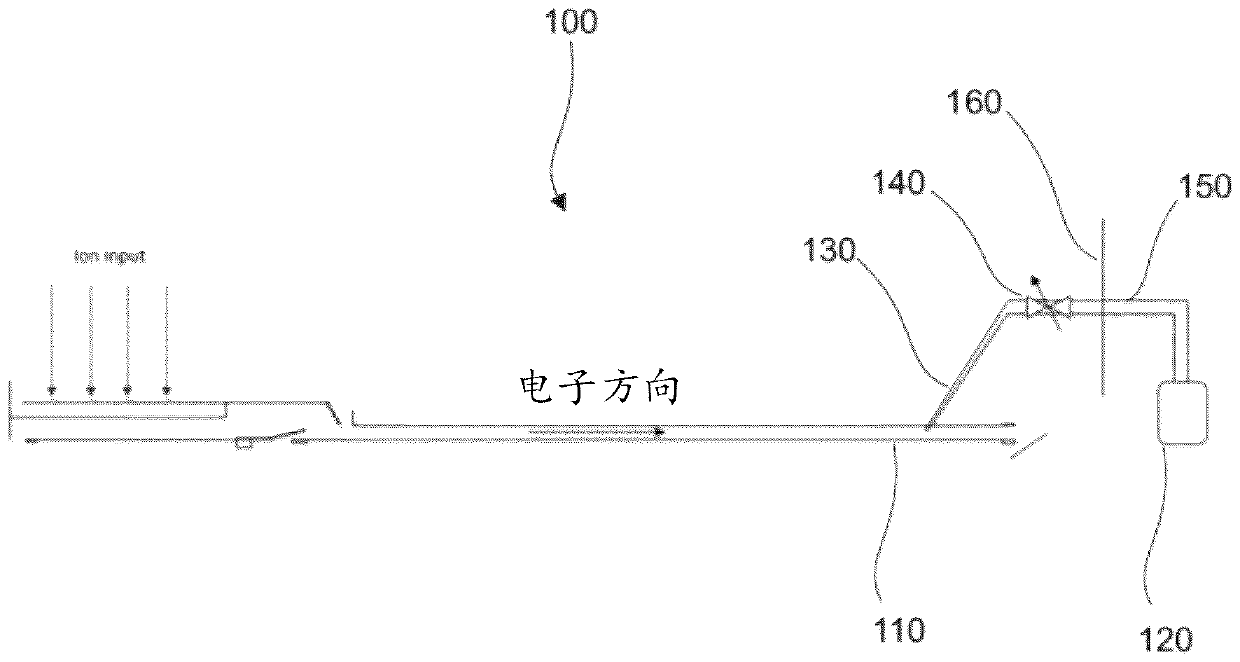

[0102] The device used is a magnetic multiplier (MagneTOF) with continuous dynodes operating in a time-of-flight mass spectrometer. The base pressure of the analyzer chamber is 1×10 -6 millibar.

[0103] During the experiment, the voltage supplied to the detector (y-axis) was adjusted to maintain 10 6 total gain. The output charge accumulated by the detector over time (unit: coulombs) is shown on the x-axis.

[0104] The plot shows that at low electron exposure levels, as the accumulated charge increases from zero, an increase in voltage is required to counteract the gain reduction. At the point indicated by the arrow, the output current is increased by a factor of 10 from 1...

example 3

[0106] Example 3: Water-assisted removal of carbonaceous pollutants.

[0107] The detector of Example 2 was modified to include a capillary extending from the inside to the outside of the detector vacuum chamber. The outdoor end of the capillary is connected to a source of gaseous water. A valve is placed between the water source and the capillary so that the amount and timing of the gaseous water can be controlled.

[0108] The detector was operated as described in Example 2, except that gaseous water was introduced at 1 mPa. The water flow is controlled at about 0.1 sccm, so the total chamber pressure is essentially unaffected, but the water is concentrated on critical surfaces.

[0109] The resulting voltage graph is similar to Figure 6 The difference is that the gain recovery portion of the graph (i.e., after the initial decay) is steeper, thus reflecting a faster (and possibly more complete) reversal of the gain decay.

[0110] refer to Figure 7 , which shows a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com