Conversion method for converting single-walled carbon nano tube into double-walled carbon nano tube

A single-walled carbon nanotube, double-walled carbon nanotube technology, applied in the directions of carbon nanotubes, nanocarbons, chemical instruments and methods, can solve the problems of low yield, narrow diameter distribution, small yield, etc., to achieve high yield, The effect of narrow diameter distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

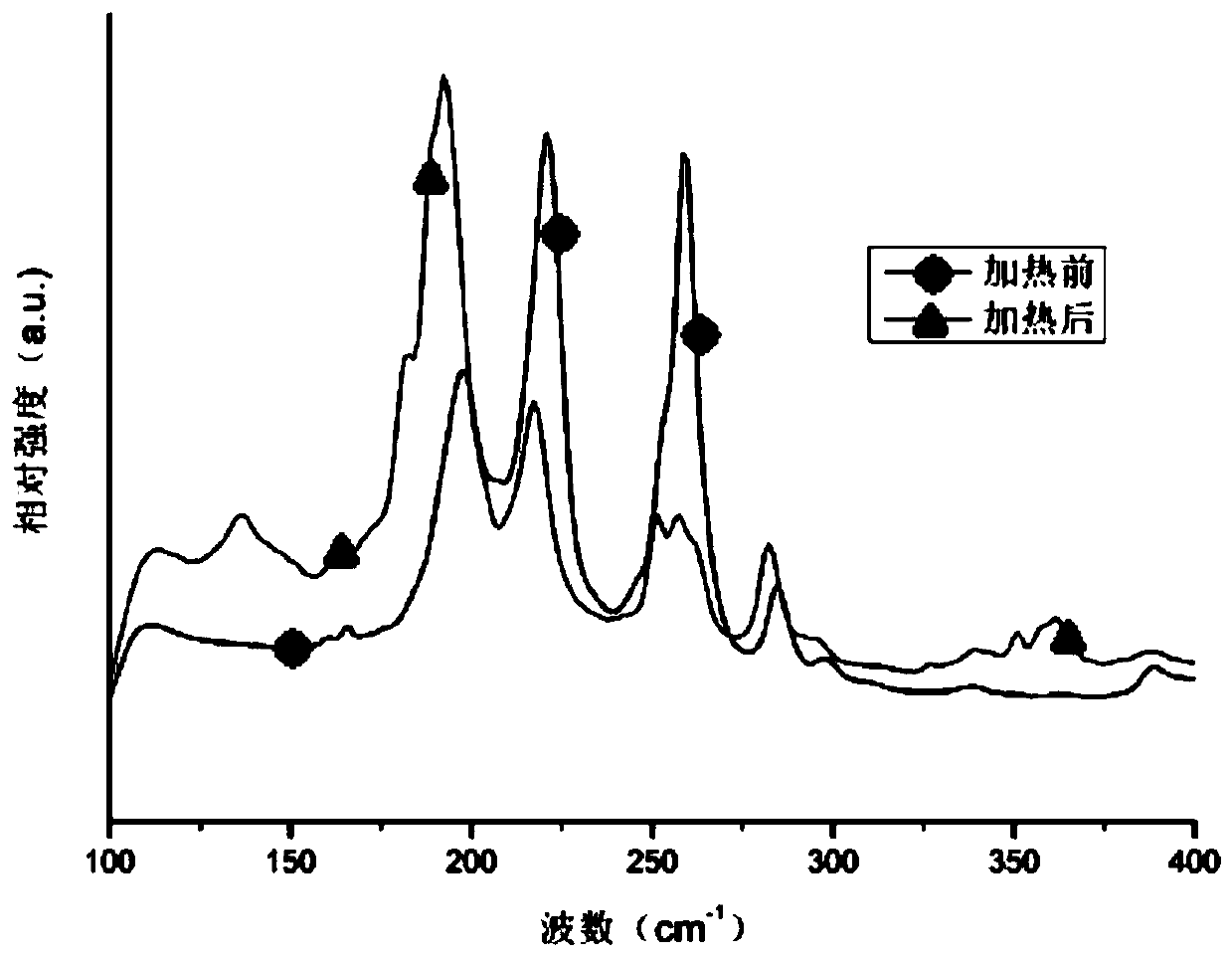

[0034] This example is a specific example of using single-walled carbon nanotubes with an average diameter of 1.1 nm to convert double-walled carbon nanotubes; in this example, the single-walled carbon nanotubes used are prepared from high-pressure carbon monoxide.

[0035] 20 mg of single-walled carbon nanotubes with an average diameter of 1.1 nm were dissolved in 20 ml of 37% hydrochloric acid solution and mixed, ultrasonically treated in a water bath for 12 minutes, and the ultrasonically completed solution was filtered using polytetrafluoroethylene with a pore size of 0.22 μm The membrane is filtered, and the filtered solution is washed three times with deionized water and rinsed once with ethanol with a concentration greater than 90%, and then dried to obtain purified single-walled carbon nanotubes.

[0036] Put the purified single-walled carbon nanotubes in an alumina boat, place the alumina boat as a whole in a high-temperature furnace, and then use a mechanical pump and...

Embodiment 2

[0040] This example is a specific example of using single-walled carbon nanotubes with an average diameter of 1.3 nm to convert double-walled carbon nanotubes; in this example, the single-walled carbon nanotubes used are prepared by pyrolysis.

[0041] 20 mg of single-walled carbon nanotubes with an average diameter of 1.3 nm are dissolved in 10 ml of 37% hydrochloric acid solution, left to soak for 20 hours, and the soaked solution is made of polytetrafluoroethylene with a pore size of 0.22 μm. filter the membrane, wash the filtered solution twice with deionized water and rinse once with ethanol with a concentration greater than 90%, and then dry to obtain purified single-walled carbon nanotubes.

[0042] Put the purified single-walled carbon nanotubes in an alumina boat, place the alumina boat as a whole in a high-temperature furnace, and then use a mechanical pump and / or a molecular pump to reduce the pressure of the high-temperature furnace to 10 -5 Pa, heat up to 1500°C a...

Embodiment 3

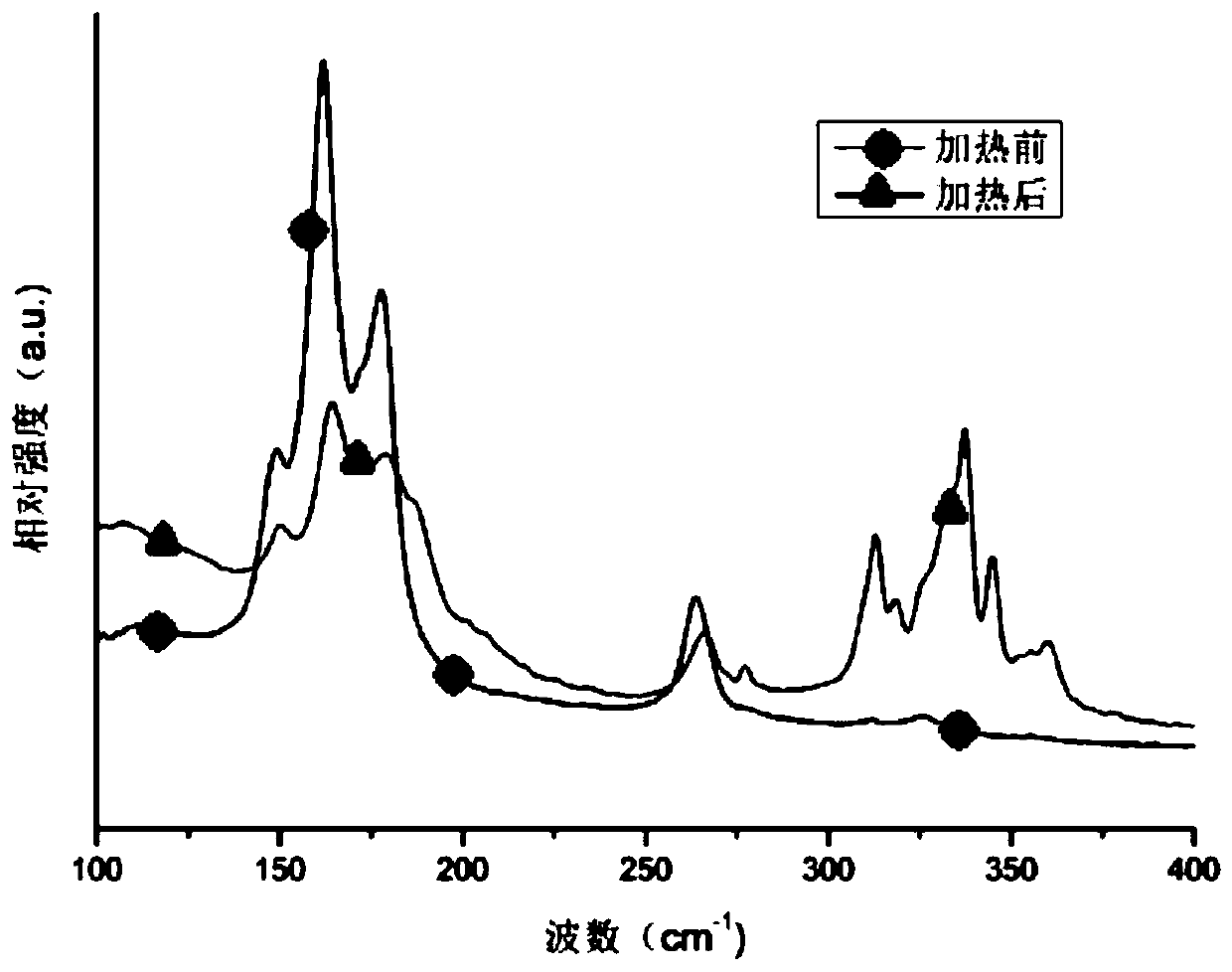

[0046] This embodiment is a specific embodiment of using single-walled carbon nanotubes with an average diameter of 1.4nm to convert double-walled carbon nanotubes; single-walled carbon nanotubes.

[0047] Place the single-walled carbon nanotubes in an alumina boat, place the alumina boat as a whole in a high-temperature furnace, and then use a mechanical pump and / or a molecular pump to reduce the pressure of the high-temperature furnace to 10 -3 Pa, heat up to 1440°C at a heating rate of 5°C / min, then heat-treat for 2 hours, and then cool down to room temperature at a cooling rate of 5°C / min to obtain double-walled carbon nanotube products.

[0048] Figure 4 In this example, the Raman spectrum characterization diagrams of carbon nanotubes before and after heat treatment, the corresponding Raman peak of the single-walled carbon nanotubes is located at about 170 wavenumbers, indicating that the diameter distribution of the single-walled carbon nanotubes is 1.46nm. Measure th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com