Tundish impact plate resistant to molten steel scouring and preparation method and construction method thereof

A tundish and impact plate technology, applied in the field of steelmaking, can solve the problems of poor molten steel impact resistance, low high temperature flexural strength, low thermal shock stability, etc., and achieves high compressive strength, low production cost, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

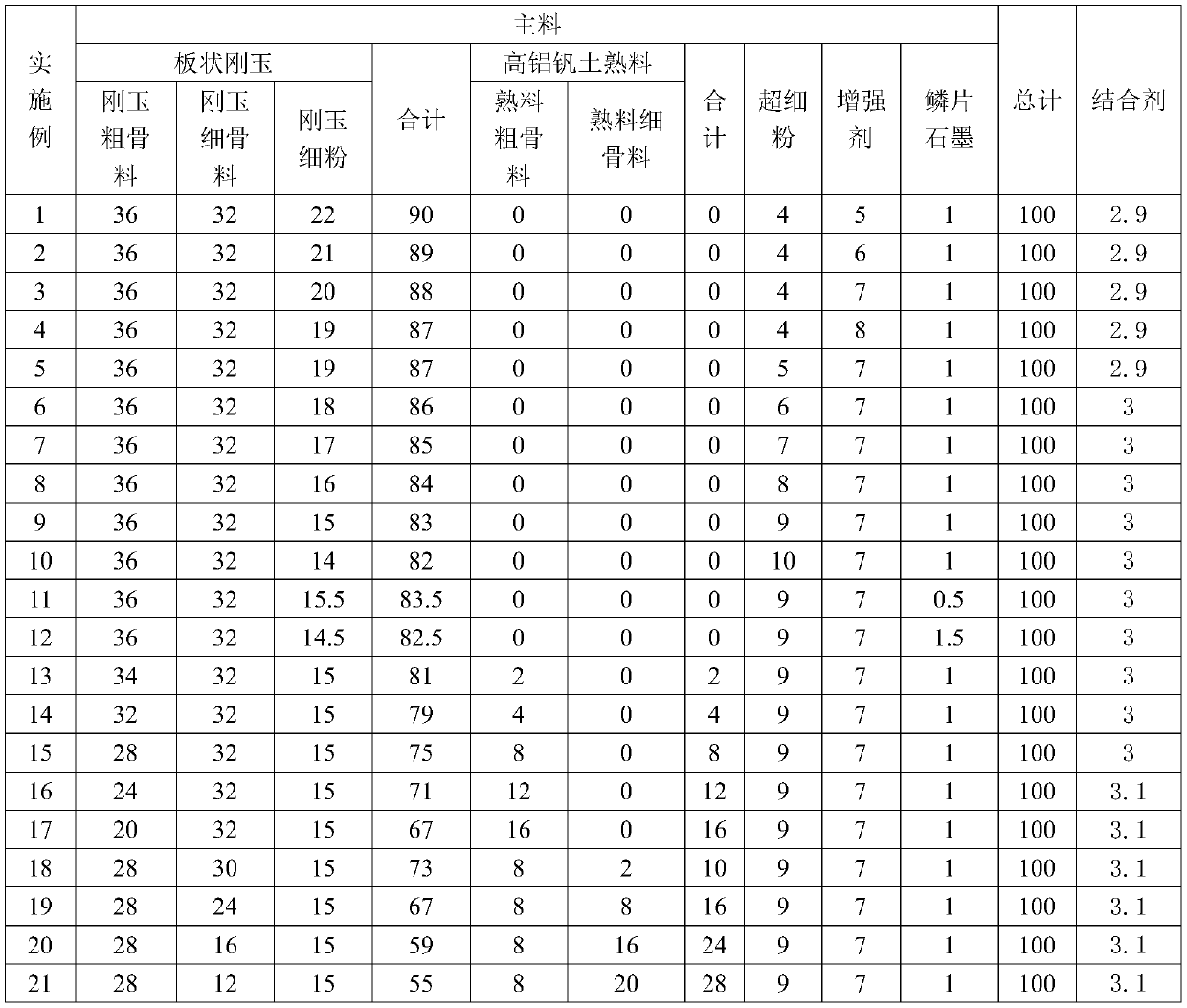

[0043] A tundish impact plate with resistance to molten steel erosion, the raw material ratio is shown in Table 1.

[0044] The preparation method of the tundish impact plate comprises the following steps:

[0045]S1. Mix the tabular corundum, superfine powder, reinforcing agent and flake graphite evenly to form the main material;

[0046] Among them, tabular corundum includes corundum coarse aggregate, corundum fine aggregate and corundum fine powder, the particle size of corundum coarse aggregate is 3-1mm, the particle size of corundum fine aggregate is less than 1mm, and the mesh number of corundum fine powder is 325 meshes; The superfine powder is alumina superfine powder, the weight content of alumina in the alumina superfine powder is 99.5%, and the average particle size is 2 μm; the reinforcing agent is metal aluminum fine powder, and the weight content of elemental aluminum in the reinforcing agent is 99.5% , the mesh number of metal aluminum fine powder is 180 mesh; ...

Embodiment 2-12

[0053] A tundish impact plate resistant to molten steel erosion, the difference between Examples 2-12 and Example 1 is that the raw material ratio of the tundish impact plate is different, and the raw material ratio is shown in Table 1.

Embodiment 13

[0055] A tundish impact plate with resistance to molten steel erosion, the raw material ratio is shown in Table 1.

[0056] The preparation method of the tundish impact plate comprises the following steps:

[0057] S1. Mix the tabular corundum, high alumina vanadium clinker, superfine powder, reinforcing agent and flake graphite evenly to form the main material;

[0058] Among them, tabular corundum includes corundum coarse aggregate, corundum fine aggregate and corundum fine powder, the particle size of corundum coarse aggregate is 3-1mm, the particle size of corundum fine aggregate is less than 1mm, and the mesh number of corundum fine powder is 325 meshes; The weight content of alumina in the high alumina vanadium soil clinker is 88%. The high alumina vanadium soil clinker includes clinker coarse aggregate and clinker fine aggregate. The particle size of the aggregate is less than 1mm; the superfine powder is alumina superfine powder, the weight content of alumina in the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap