High-temperature-resistant and high-humidity-resistant retard-bonded prestressed twisted steel and preparation method thereof

A technology of slow-bonding prestressed, threaded steel bars, applied in adhesives, adhesive types, epoxy resin adhesives, etc., can solve the problems of high temperature and high humidity resistance, poor high and low temperature alternating performance, etc. Low temperature alternating performance, simple preparation process, good high temperature resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

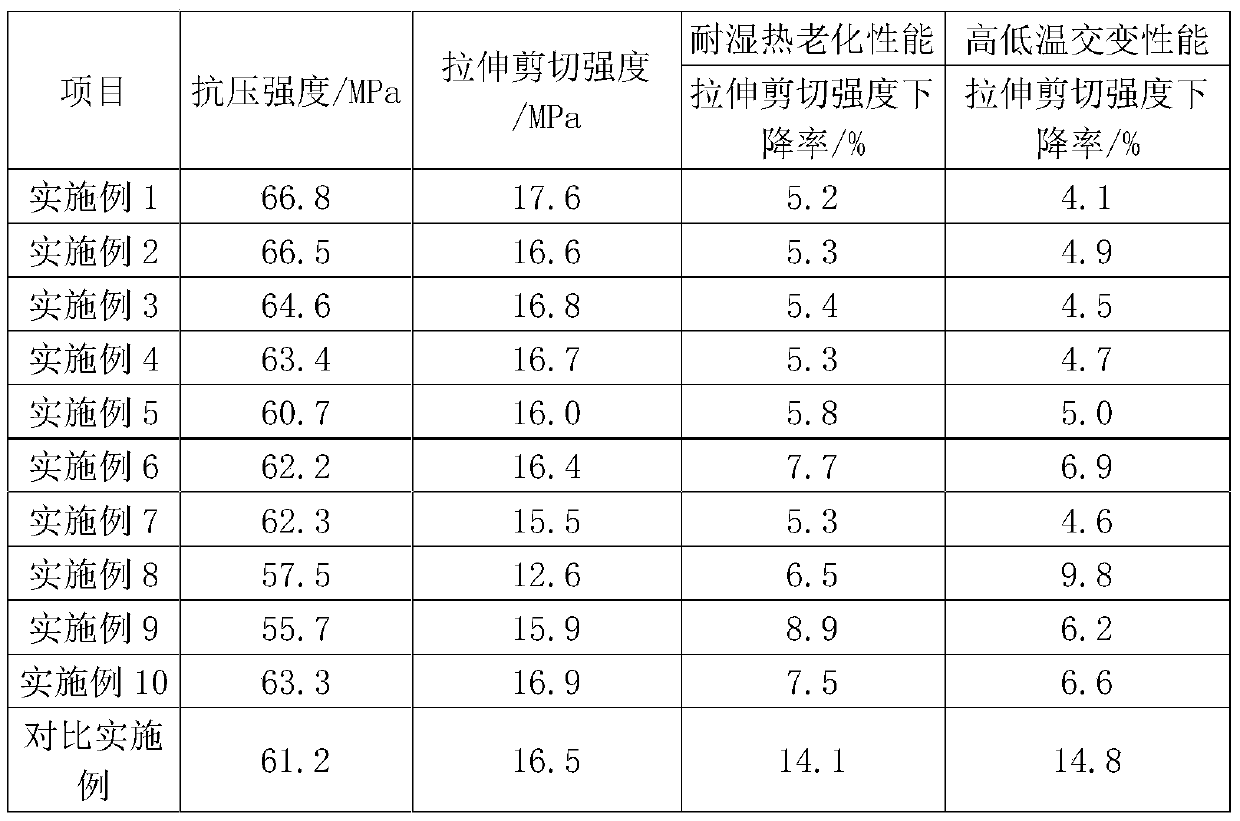

Examples

preparation example 1

[0044] 1. Add 2,2-difluoromalonic acid and triethylenetetramine with a molar ratio of carboxyl group to primary amino group of 1:1.3 into the reactor under nitrogen atmosphere, pressurize to 0.3MPa, and wait for 1.5h Heat up to 160°C while stirring inside, at this time the pressure rises to 1.8MPa, keep the pressure constant by intermittently removing the generated water vapor and keep the temperature in the kettle at 160°C for 2 hours;

[0045] 2. Release the pressure of the reactor to normal pressure, and react at a constant temperature of 160°C; then evacuate to -0.08MPa, and react at a constant temperature of 160°C, and finally pressurize the reactor to normal pressure and lower the temperature to 60°C, continue to stir and react at a constant temperature for 1h ;

[0046] 3. Cool the reactor to 23°C, stop stirring, and discharge the material to obtain the fluorine-containing polyamide.

preparation example 2

[0048] The rest is the same as Preparation Example 1, except that in step 1, the temperature is raised to 130°C while stirring within 2h, and finally the generated water vapor is kept constant by intermittently removing the pressure and the temperature in the kettle is kept at 130°C for 3h;

preparation example 3

[0050] The rest are the same as in Preparation Example 1, except that 2,2-difluoromalonic acid and triethylenetetramine with a molar ratio of carboxyl and primary amino groups of 1:1.1 are added to a reactor under a nitrogen atmosphere for reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com