Separating and screening method of source sludge reduction strain

A technology for separation and screening of strains is applied in the field of residual sludge treatment in sewage treatment plants, which can solve the problems of immature strain screening methods of sludge, and achieve the effect of avoiding secondary pollution and reducing output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for isolating and screening bacterial strains for reducing sludge at source, including the isolation of bacterial strains and further screening of bacterial strains.

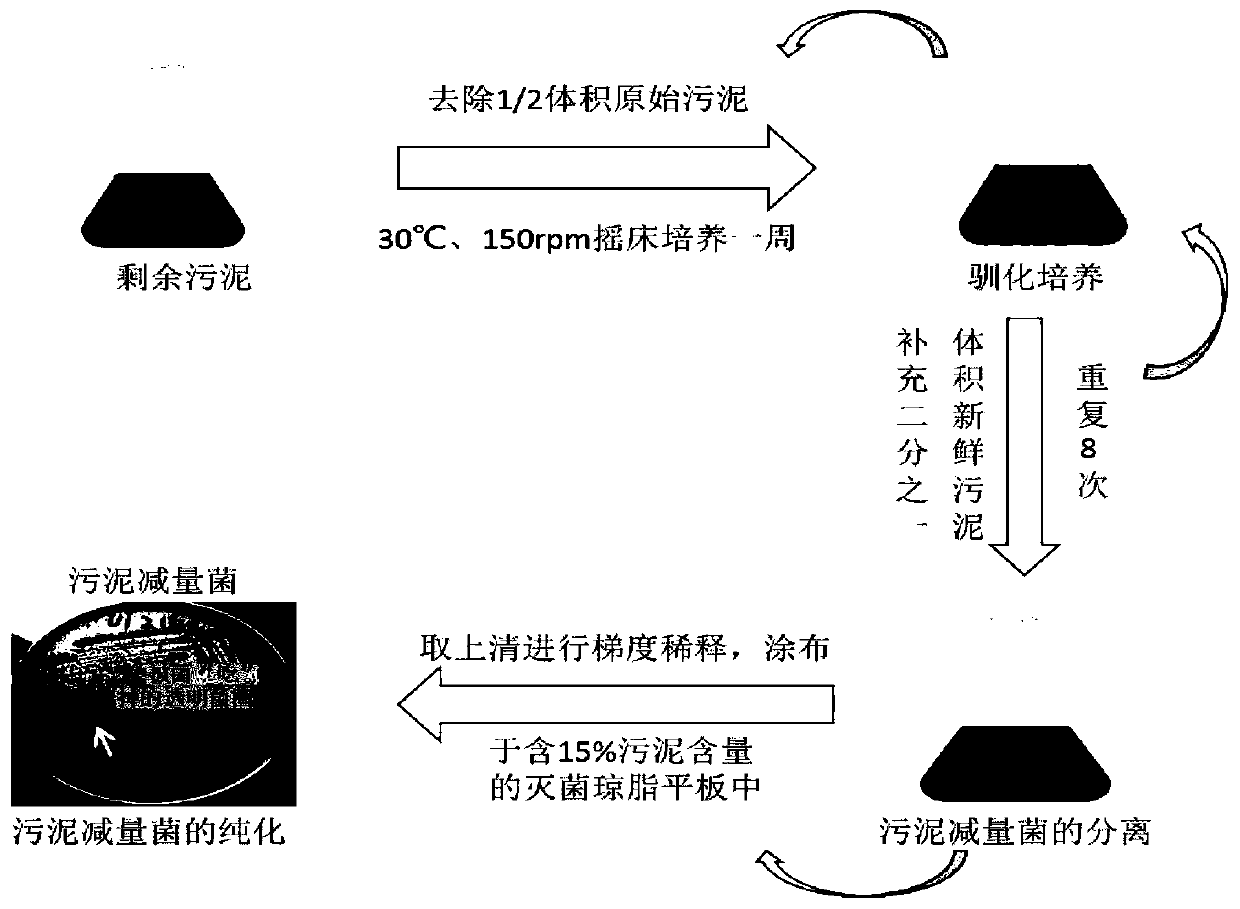

[0030] Isolation of strains such as figure 1 Shown: Take the fresh sludge from the sewage treatment plant and put it into a 500mL Erlenmeyer flask, seal the mouth of the Erlenmeyer flask with aluminum foil to prevent evaporation, then shake it in a shaker at 30°C and 60 rpm for one week. Then remove 1 / 2 of the original sludge, add the same volume of fresh sludge, and carry out the same steps 8 times. Select the domesticated activated sludge, and carry out gradient dilution for 10 -6 、10 -7 、10 -8 、10 -9 、10 -10 、10 -11 、10 -12 , spread on sterilized agar plate medium containing sludge (preparation method: 50 g centrifugal sludge, 300 mL sterile water, 4.5 g agar, mix well, put in 500 mL Erlenmeyer flask and place in autoclaved Sterilization in the bacteria pot, after sterilization, invert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com