Manufacturing method of thick copper printed circuit board

A technology of printed circuit board and manufacturing method, which is applied in the directions of printed circuit manufacturing, printed circuit, and printed circuit secondary processing, etc., can solve the problem of long etching process, corrosion of thick copper sides of design lines, affecting product performance and quality, etc. problem, to improve the protection performance, avoid sundries from adhering to the surface of the circuit, and improve the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

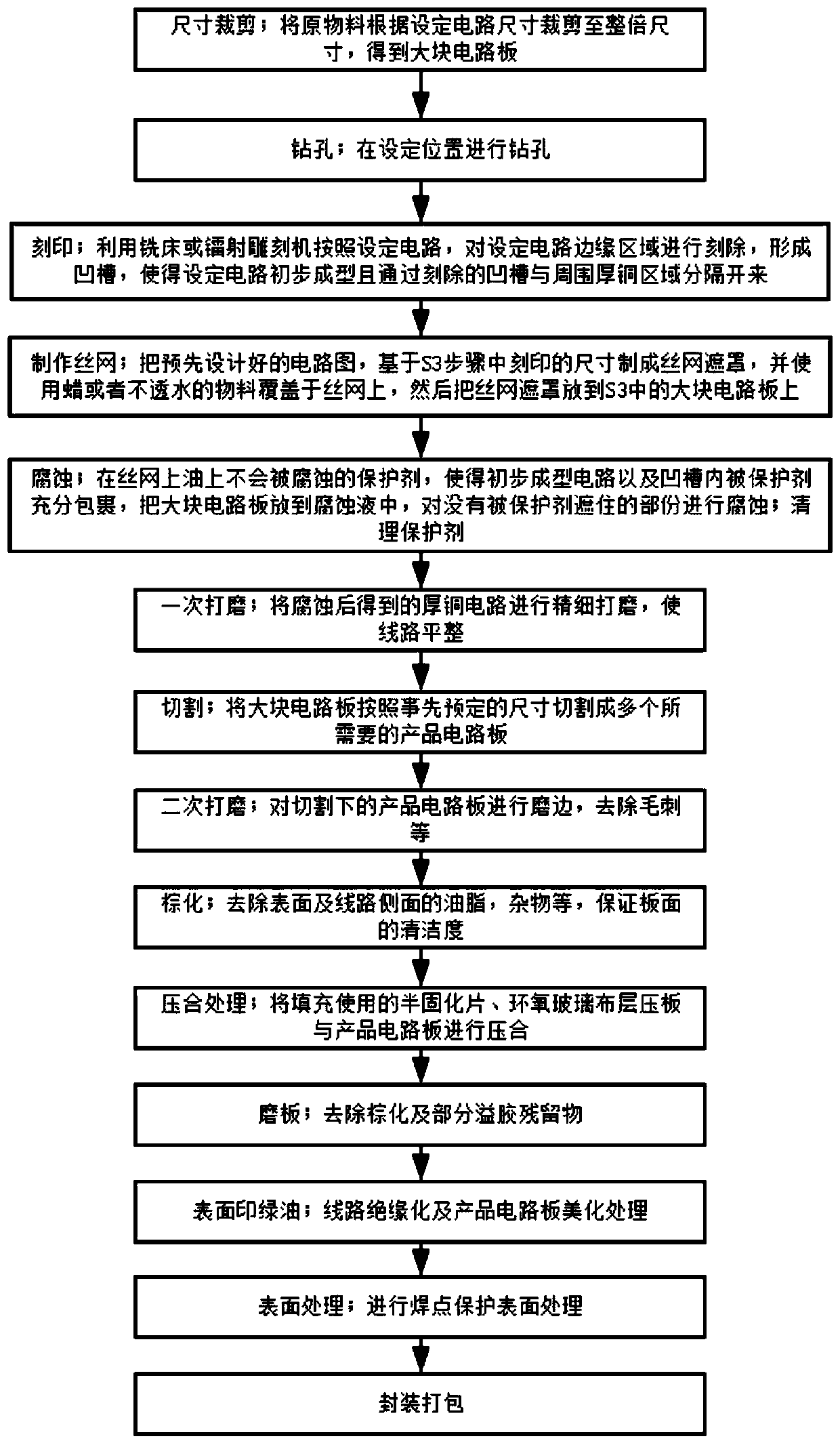

[0070] A kind of manufacture method of thick copper printed circuit board, such as figure 1 As shown, the following steps are included in sequence:

[0071] S1: Size cutting; cut the raw material to the full size according to the set circuit size to obtain a large circuit board;

[0072] S2: drilling; drilling at the set position;

[0073] S3: Engraving; use a milling machine or a laser engraving machine to carve out the edge area of the set circuit according to the set circuit to form a groove, so that the set circuit is initially formed and separated from the surrounding thick copper area by the engraved groove Come;

[0074] S4: Make a silk screen; make a screen mask based on the pre-designed circuit diagram based on the size engraved in step S3, and use wax or impermeable material to cover the screen, and then put the screen mask in S3 on a large circuit board;

[0075] S5: Corrosion; apply a protective agent that will not be corroded on the screen oil, so that the p...

Embodiment 2

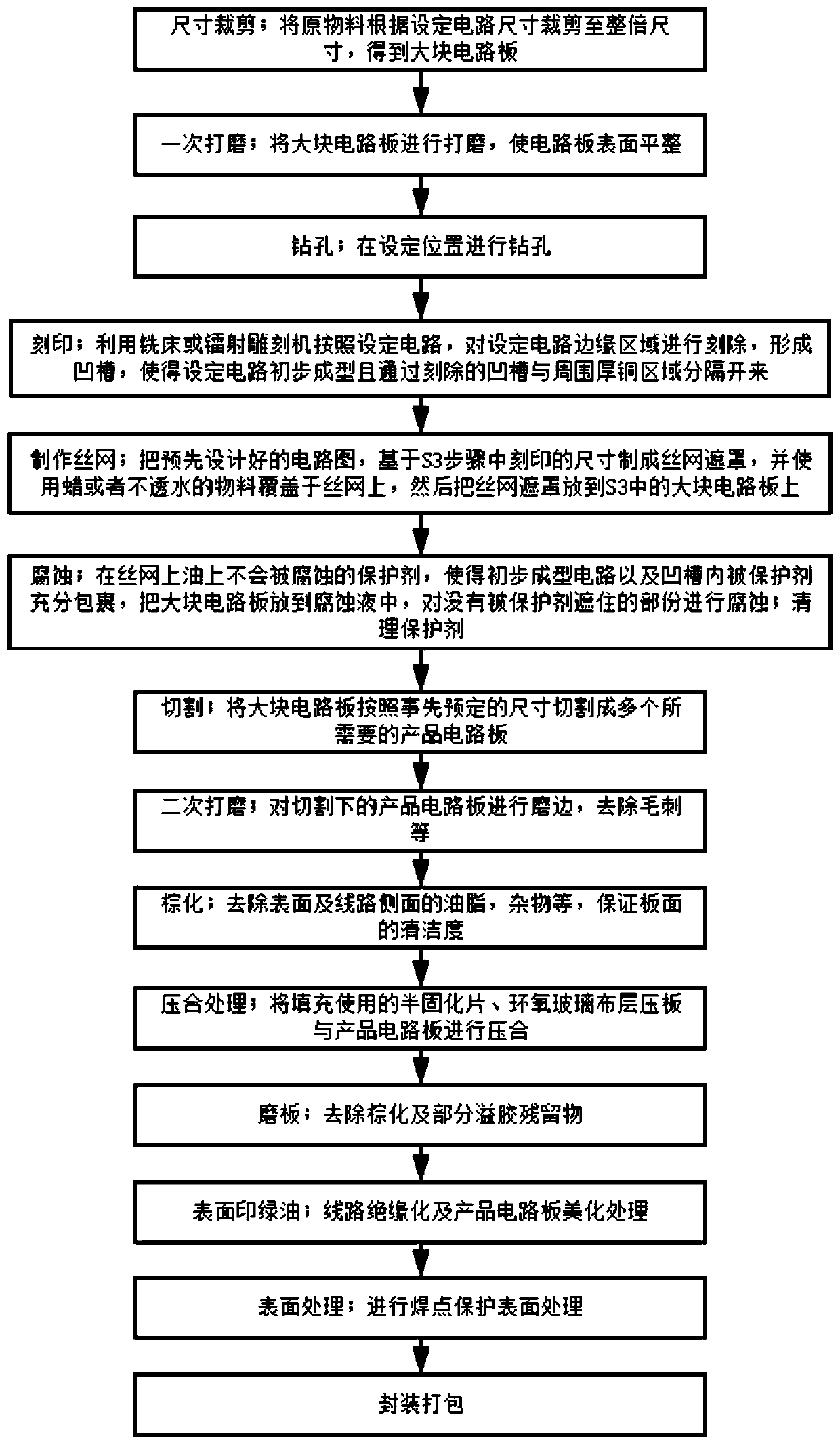

[0089] A kind of manufacture method of thick copper printed circuit board, such as figure 2 As shown, the following steps are included in sequence:

[0090] S1: Size cutting; cut the raw material to the full size according to the set circuit size to obtain a large circuit board;

[0091] S2: Grinding once; Grinding the large circuit board to make the surface of the circuit board smooth;

[0092] S3: drilling; drilling at the set position;

[0093] S4: Engraving; use a milling machine or laser engraving machine to carve out the edge area of the set circuit according to the set circuit to form a groove, so that the set circuit is initially formed and separated from the surrounding thick copper area by the engraved groove Come;

[0094] S5: Make a silk screen; make a screen mask based on the pre-designed circuit diagram based on the size engraved in step S3, and use wax or impermeable material to cover the screen, and then put the screen mask in S3 on a large circuit board...

Embodiment 3

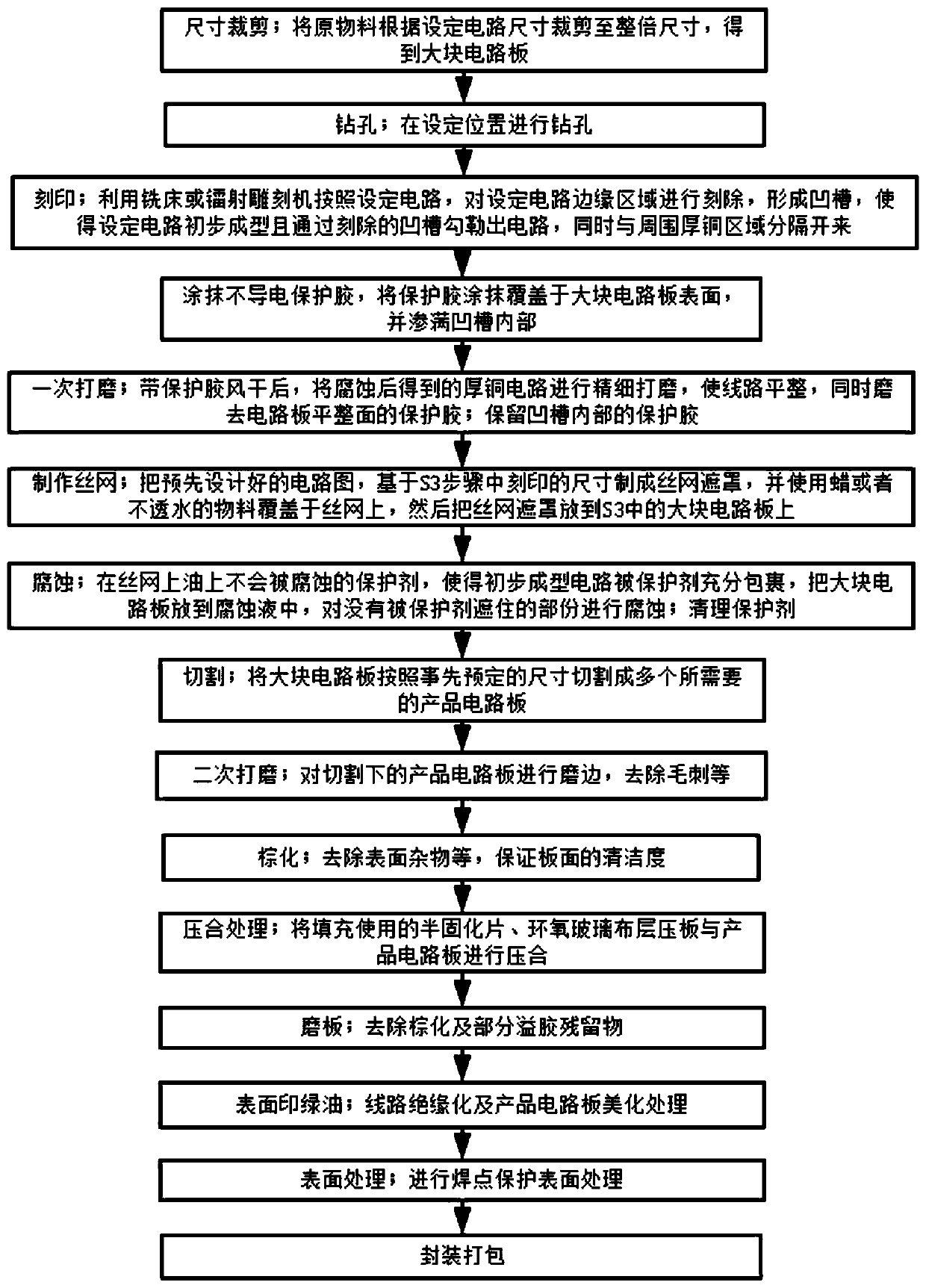

[0108] A kind of manufacture method of thick copper printed circuit board, such as figure 2 As shown, the following steps are included in sequence:

[0109] S1: Size cutting; cut the raw material to the full size according to the set circuit size to obtain a large circuit board;

[0110] S2: Grinding once; Grinding the large circuit board to make the surface of the circuit board smooth;

[0111] S3: drilling; drilling at the set position;

[0112] S4: Engraving; use a milling machine or laser engraving machine to carve out the edge area of the set circuit according to the set circuit to form a groove, so that the set circuit is initially formed and separated from the surrounding thick copper area by the engraved groove Come;

[0113] S5: Make a silk screen; make a screen mask based on the pre-designed circuit diagram based on the size engraved in step S3, and use wax or impermeable material to cover the screen, and then put the screen mask in S3 on a large circuit board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com