Industrial solid waste recycling cyclic utilization device

A solid waste and recycling technology, which is applied to the removal of solid waste, chemical industry, petroleum industry, etc., can solve the problems that affect the internal cleanliness of the device, easily cause accumulation, reduce the crushing effect, etc., achieve sufficient removal of impurities and heating, and improve Recycling efficiency and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

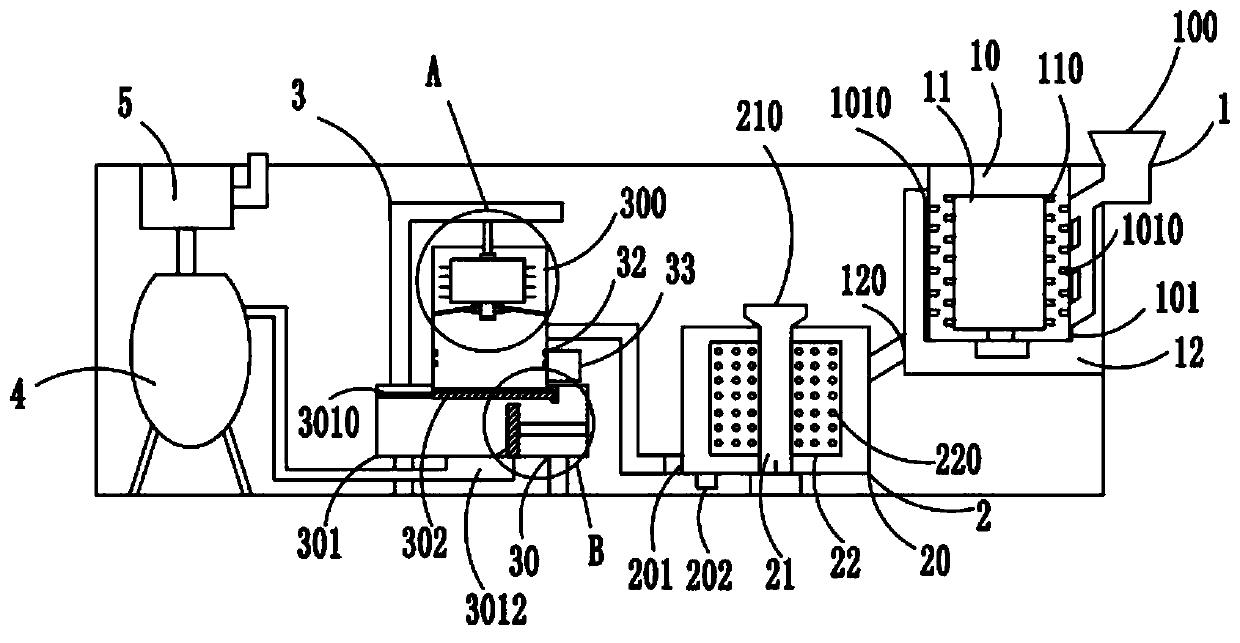

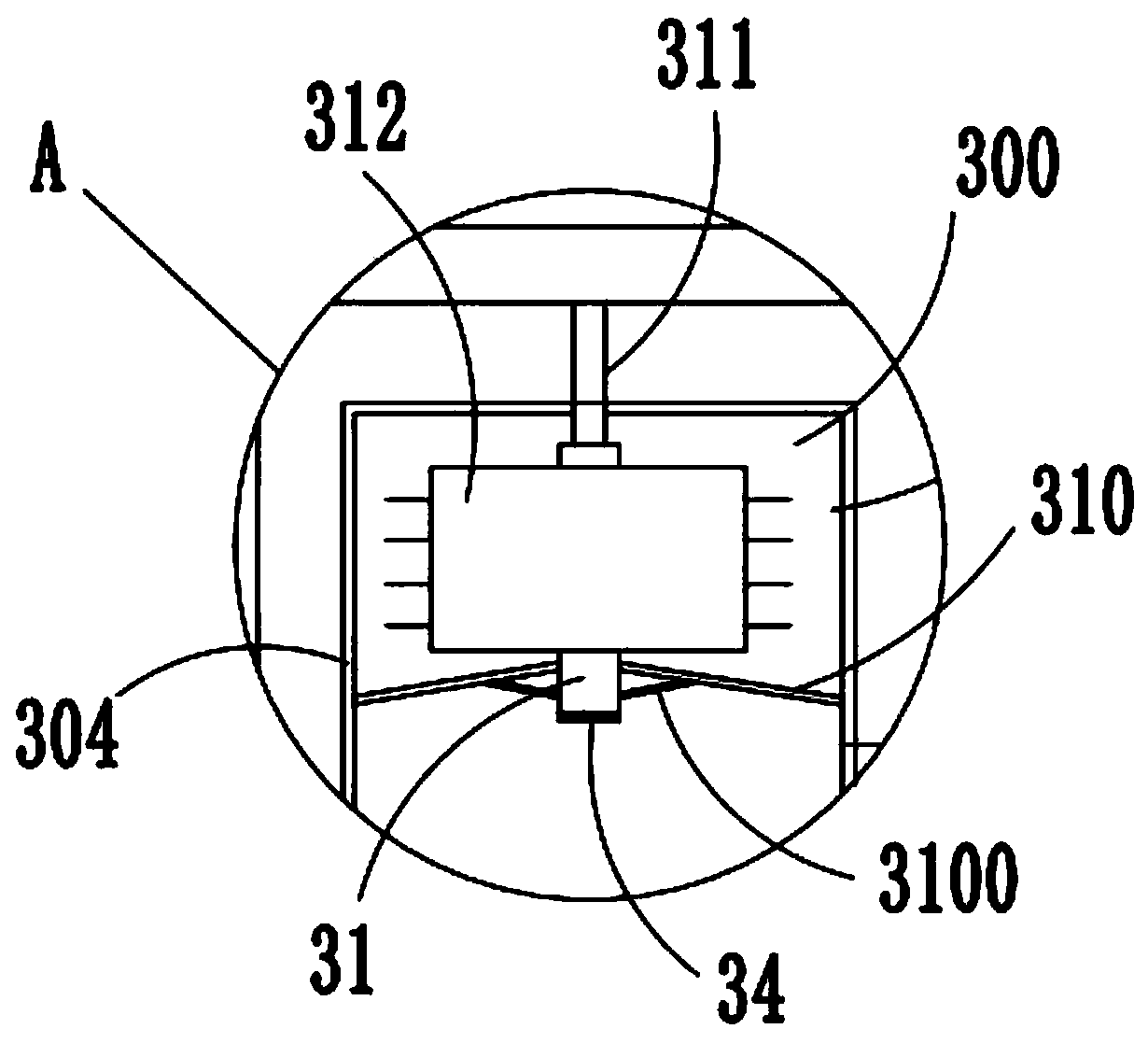

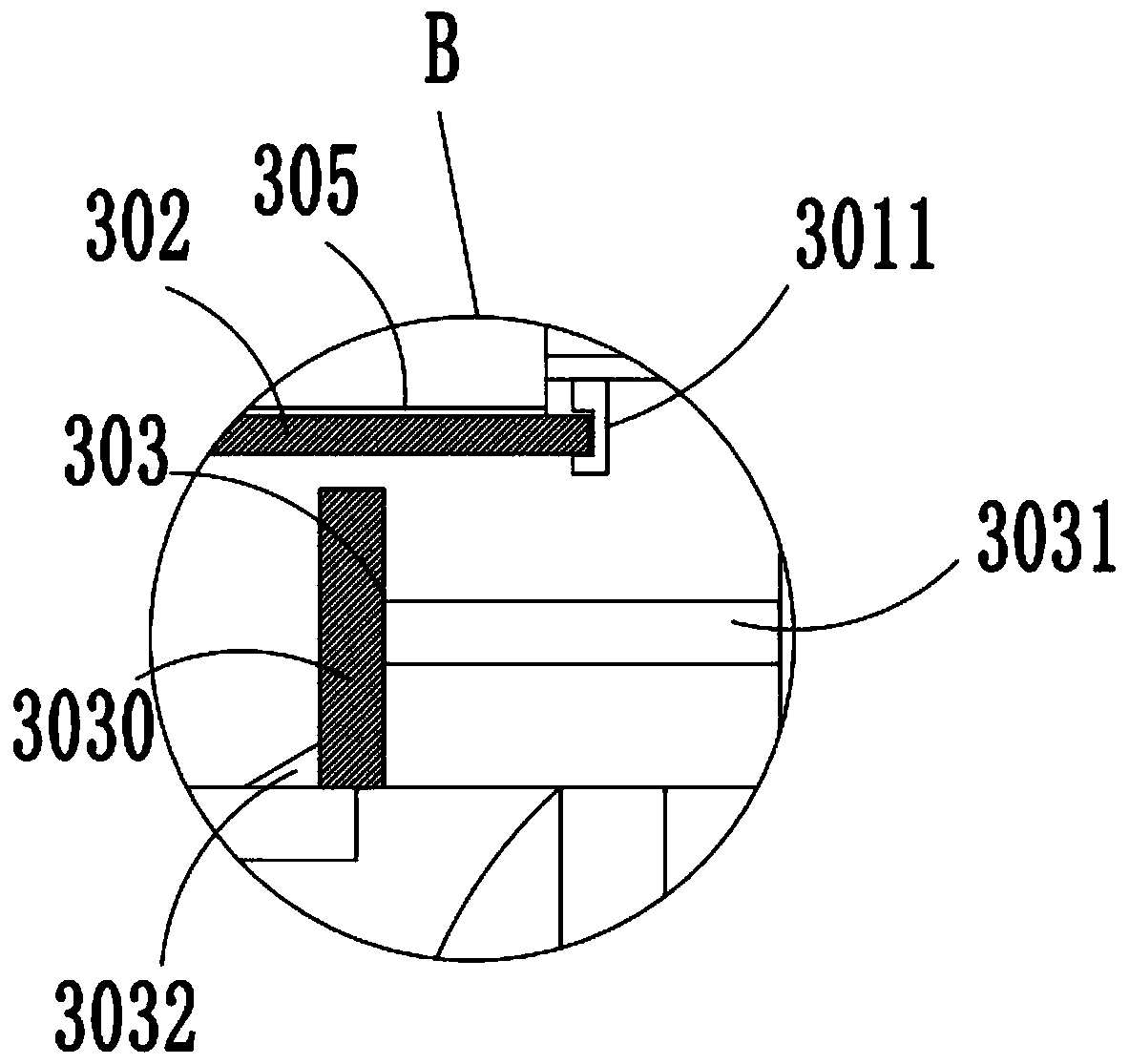

[0036] Example: such as figure 1 The shown industrial solid waste resource recycling device mainly includes a screening and crushing element 1 for crushing waste materials, a mixing and impurity removal element 2 for pretreating the waste processed by the screening and crushing element 1, and a mixing The waste material drying element 3 for drying the waste after the pretreatment of the impurity removal element 2, the pyrolysis furnace 4 for performing high-temperature heat treatment on the waste material treated by the waste material drying element 3, and the dust removal for the gas generated by pyrolysis in the pyrolysis furnace 4 5. A power supply electrically connected to each electrical component;

[0037] The screening and crushing element 1 includes a side wall provided with a material inlet 100 and a filter screen 101 provided on the side wall, and a pulverizing inner cylinder 10 with ten pulverizing knives-1010 evenly arranged on the inner wall of the filter screen 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com