Horizontal deacidification furnace for producing high-temperature water vapor based on hydrogen combustion method

A high-temperature steam and combustion technology, applied in the direction of silica, silicon oxide, etc., can solve the problems of low deacidification efficiency, low quality and serious agglomeration of fumed silica, and achieve low energy consumption and stable and uniform airflow. , the effect of uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

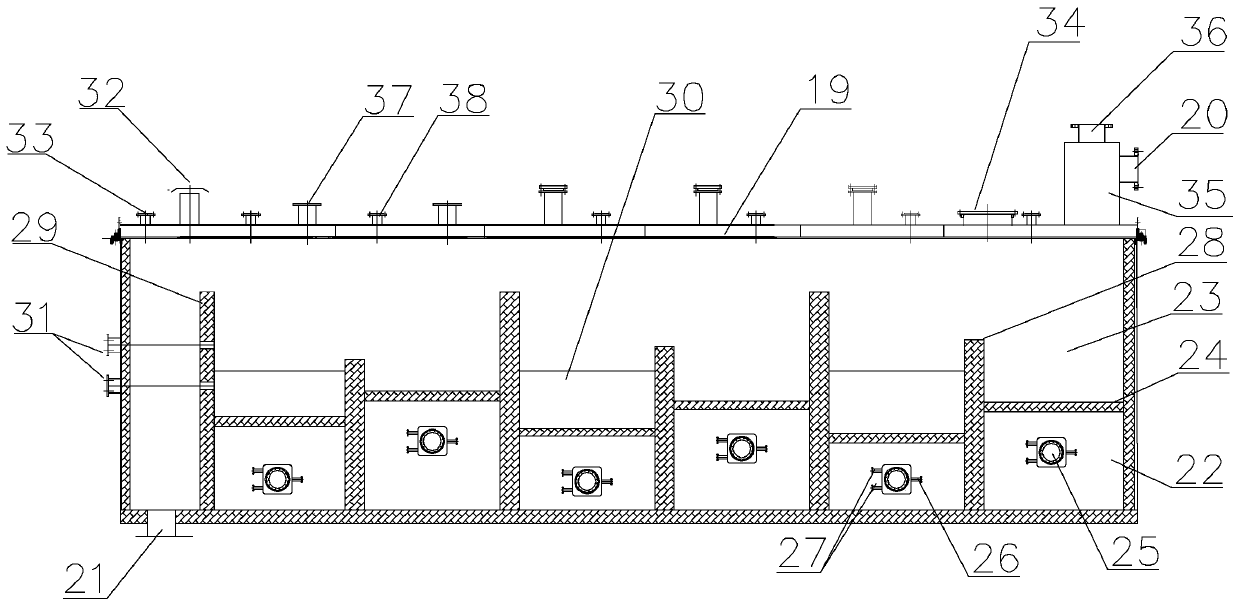

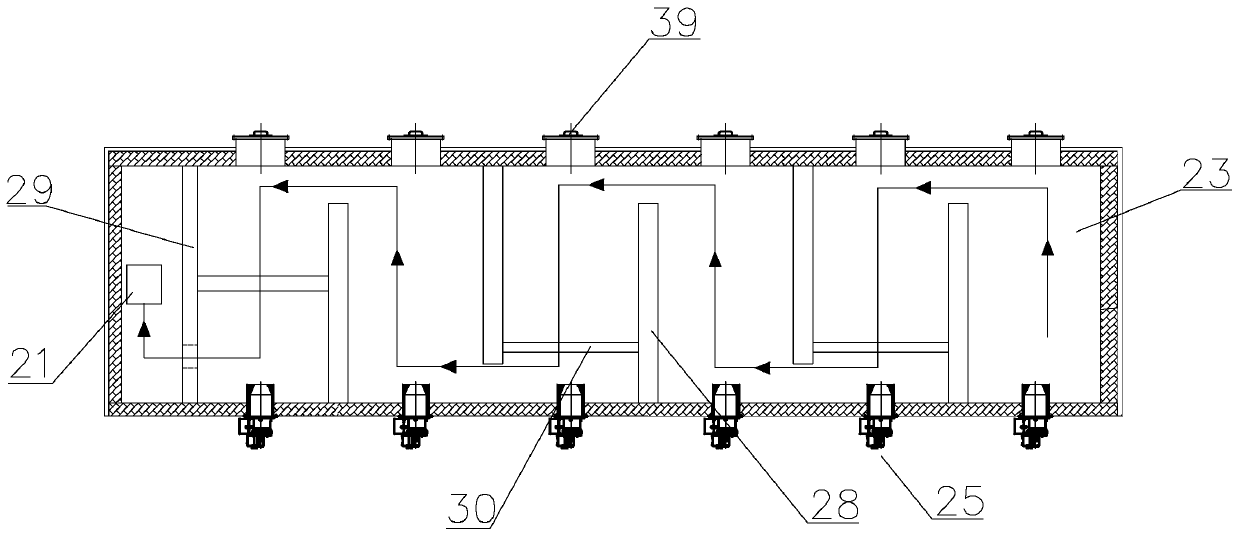

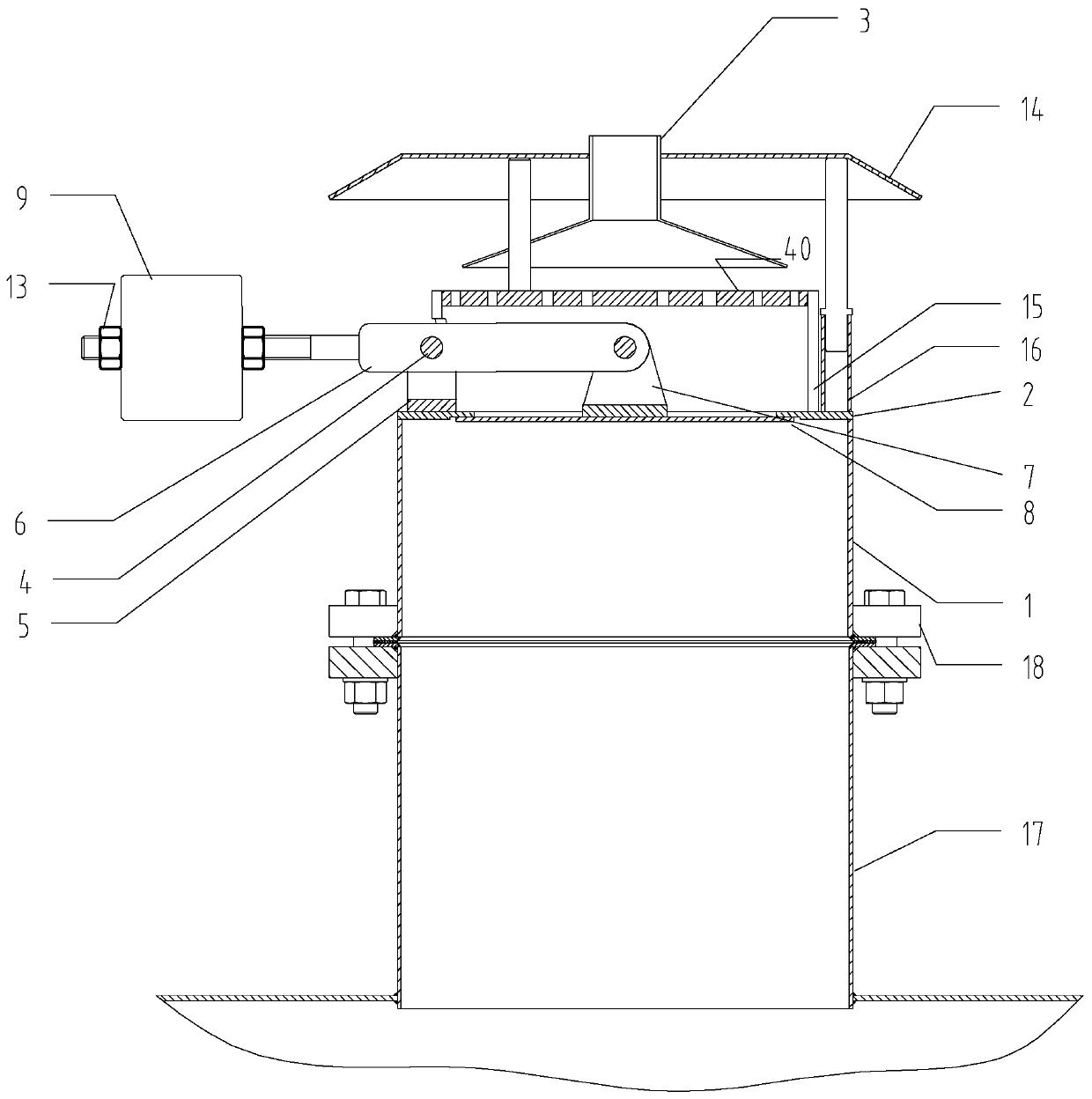

[0063] like figure 1 Shown, a kind of horizontal deacidification furnace that produces high-temperature water vapor based on the hydrogen combustion method includes a body of furnace 19, and the top of the head end of the body of furnace is provided with a cyclone separator 35; the cyclone separator is provided with an exhaust port 36 and The feed port 20, the bottom of the tail end is provided with a discharge port 21; the bottom of the furnace body is provided with six combustion chambers 22, and the top of the combustion chamber is a fluidization chamber 23, and a gas distributor 24 is passed between the combustion chamber and the fluidization chamber Isolation; each combustion chamber is provided with a burner 25; each burner is provided with a hydrogen inlet 26 and two air inlets 27; the fluidization chamber is provided with five staggered baffles 28 to form an S-shaped flow Road (such as figure 2 As shown), the rear end of the baffle at the end is provided with a barri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com