Phytate composite flame retardant for polyamide and preparation method of phytate composite flame retardant

A composite flame retardant and phytate technology, which is applied in the field of flame retardant preparation, can solve problems such as poor compatibility, and achieve the effects of improved compatibility, simple preparation method, and excellent flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

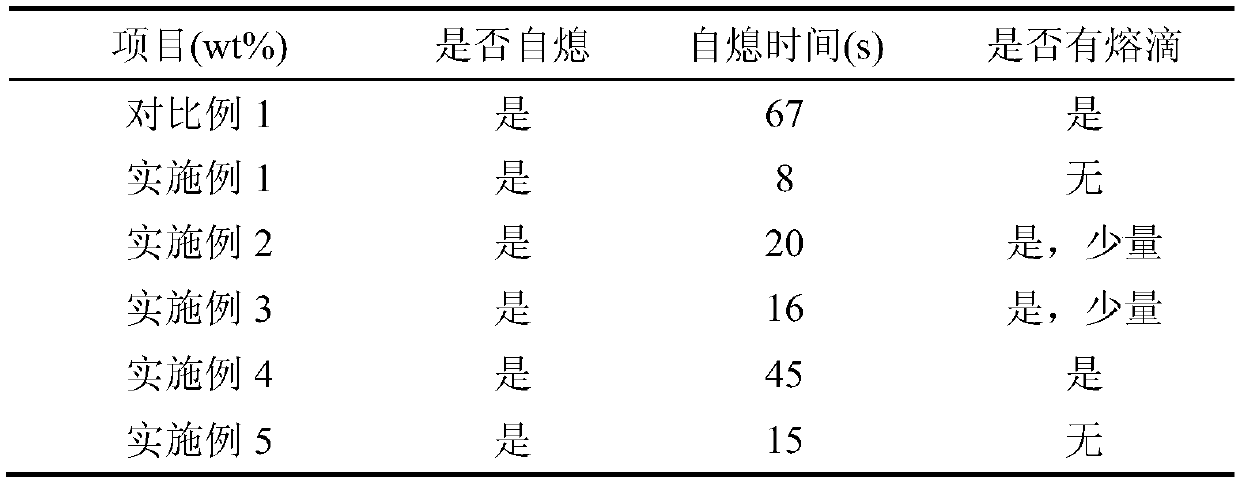

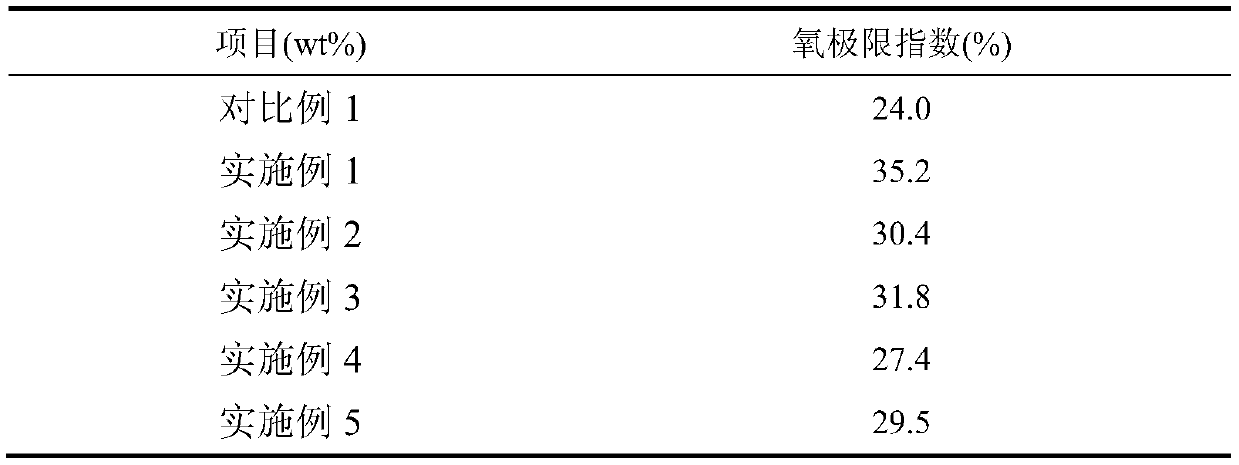

Examples

Embodiment 1

[0026] Dissolve 10 g of tributylmethylammonium chloride and 0.2 mol of zinc acetate in 250 mL of ethanol, and stir evenly to obtain a colorless and transparent zinc acetate-ionic liquid alcohol solution. Dissolve 30 g of phytic acid (50% aqueous solution) in 150 mL of ethanol, stir evenly to obtain a phytic acid water-ethanol solution, place the solution in a constant pressure dropping funnel, and slowly add it dropwise to the zinc acetate-ionic liquid ethanol solution , a white precipitate will be produced during the dropwise addition. After the dropwise addition, the stirring reaction was continued for 2 h, and the mechanical stirring speed was maintained at 450 r / min. After the reaction was completed, a white suspension was obtained, which was placed in an oven at 80°C for 24 hours, and the suspension was layered. The upper layer was a colorless and transparent clear liquid, and the lower layer was a white precipitate. Wash the precipitate 5 times with deionized water and ...

Embodiment 2

[0028] The ionic liquid functionalized nickel phytate was prepared, and other processes were the same as those in Example 1.

Embodiment 3

[0030] The ionic liquid functionalized cobalt phytate was prepared, and the remaining processes were the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com