Yttrium-scandium-iron alloy material, yttrium-titanium-scandium-iron alloy material, preparation method and application

A ferroalloy and alloy block technology, applied in the field of hydrogen storage alloy materials, can solve the problems of reversible hydrogen storage capacity decay, unfavorable commercial application, unstable material structure, etc., and achieve small cycle hysteresis, improved dehydrogenation performance, and structural stability. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] On the other hand, the preparation method of the yttrium-scandium-iron alloy material provided by the embodiment of the present invention may include the following steps:

[0068] Step S11: Weighing the bulk metal materials of yttrium, scandium and iron according to the ratio of the substances in the general chemical formula, mixing them, melting them at a temperature higher than 1600° C., and obtaining alloy ingots after cooling.

[0069] As can be seen from the foregoing, the general chemical formula of yttrium, scandium and iron is Y 1-x sc x Fe 2 , where 0.3≤x≤0.5. For a given x, the ratio of the amount of matter of the three metal materials is determined. By mixing the weighed metal bulk materials of yttrium, scandium and iron, it is ensured that they are evenly mixed with each other, which is beneficial to the subsequent smelting process.

[0070] In one embodiment, the smelting process for the three metal materials specifically includes: repeated smelting in ...

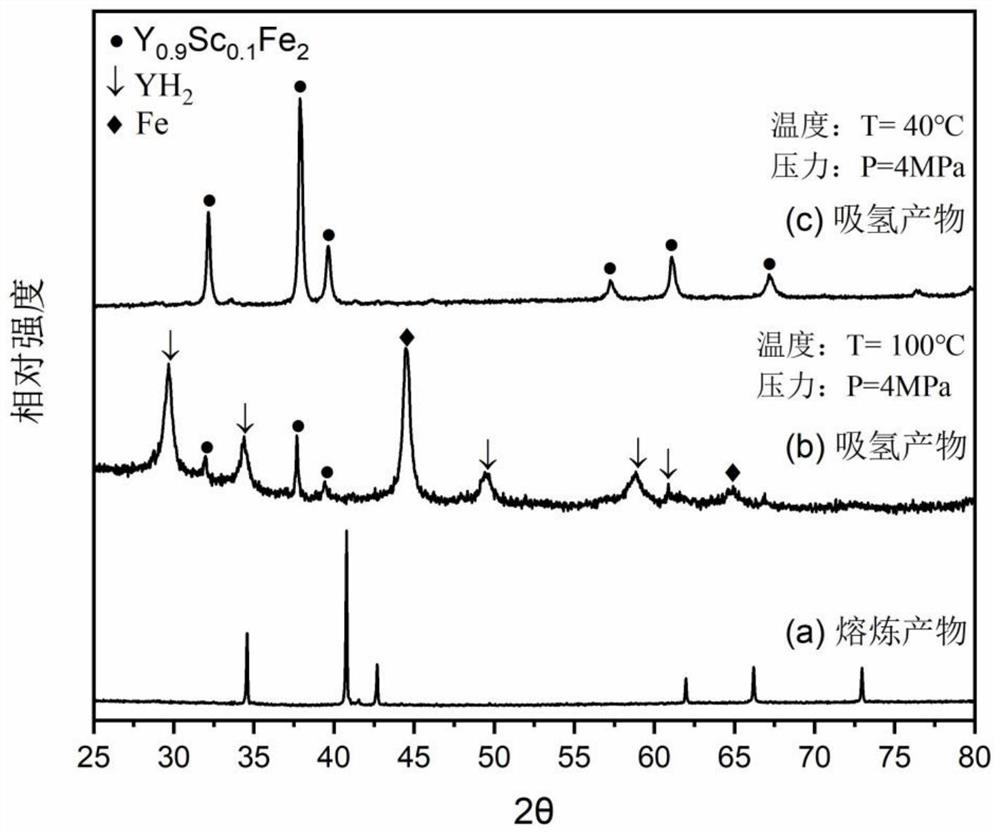

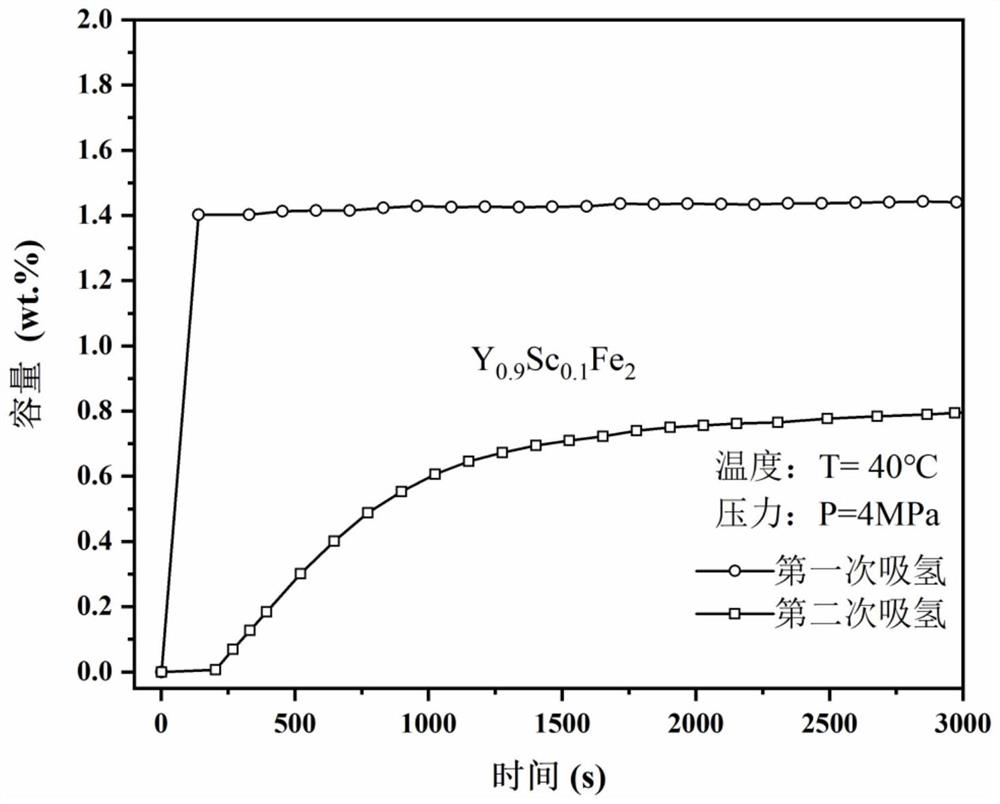

Embodiment 1

[0090] This embodiment provides a yttrium-scandium-iron alloy material, the general chemical formula of the yttrium-scandium-iron alloy material is Y 0.9 sc 0.1 Fe 2 , the preparation method of yttrium-scandium-iron alloy material comprises the steps:

[0091] Step S311: According to the general chemical formula Y 0.9 sc 0.1 Fe 2 The ratio of the amount of material is to weigh metal blocks of yttrium, scandium and iron, melt them in an arc melting furnace at 1600 ° C for 5 minutes, and obtain alloy ingots after cooling;

[0092] Step S312: turning over the obtained alloy ingot, melting and cooling again, and repeating the melting process 6 times. Re-melting is carried out in an electric arc melting furnace with a melting temperature of 1600°C and a melting time of 5 minutes;

[0093] Step S313: Place the obtained alloy ingot into a quartz tube and seal it, and pump the air pressure in the quartz tube to 5×10 -5 Pa;

[0094] Step S314: placing the quartz tube in a box-t...

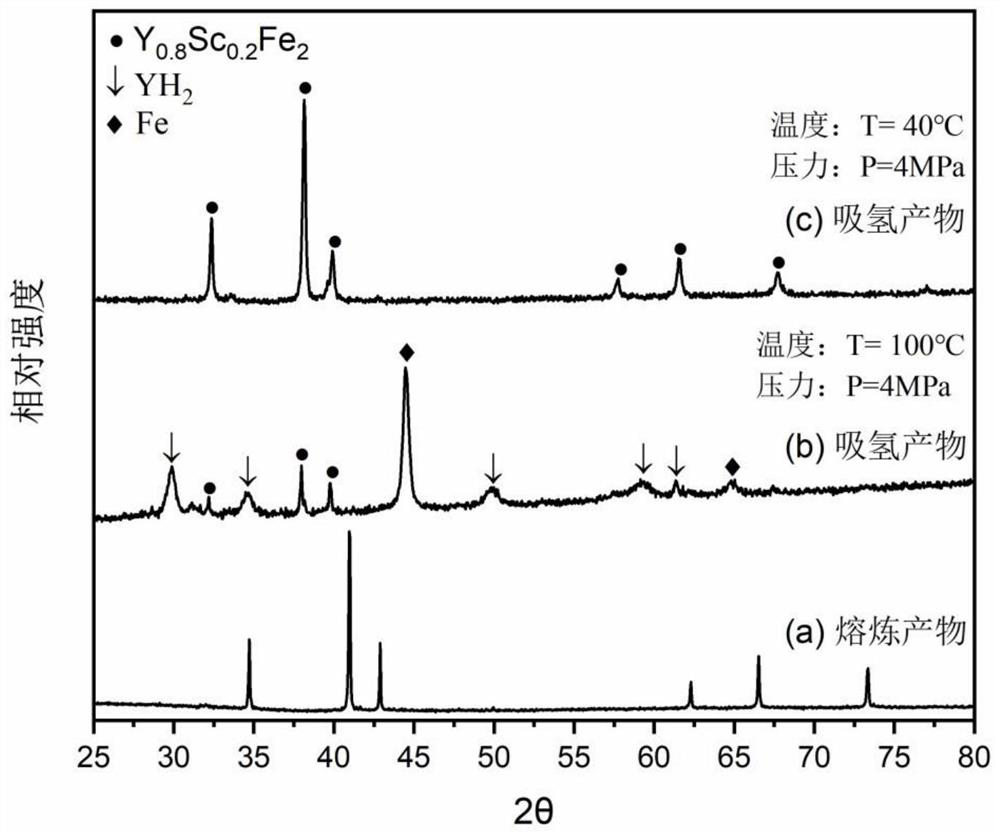

Embodiment 2

[0099] This embodiment provides a yttrium-scandium-iron alloy material, the general chemical formula of the yttrium-scandium-iron alloy material is Y 0.8 sc 0.2 Fe 2 , the preparation method of yttrium-scandium-iron alloy material comprises the steps:

[0100] Step S321: According to the general chemical formula Y 0.8 sc 0.2 Fe 2 The ratio of the amount of material is to weigh metal blocks of yttrium, scandium and iron, melt them in an arc melting furnace at 1600 ° C for 5 minutes, and obtain alloy ingots after cooling;

[0101] Step S322: Turn over the obtained alloy ingot, melt and cool again, and repeat the melting process 6 times. Re-melting is carried out in an electric arc melting furnace with a melting temperature of 1600°C and a melting time of 5 minutes;

[0102] Step S323: Place the obtained alloy ingot into a quartz tube and seal it, and pump the air pressure in the quartz tube to 5×10 -5 Pa;

[0103] Step S324: annealing the quartz tube in a box-type resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com