Tinning brightener and preparing method thereof

A brightener and tin-plating technology, applied in the field of tin-plating brightener and its preparation, can solve the problems of low brightness of tin-plating brightener, and achieve the effects of improving preparation effect and success rate, improving brightness and improving chemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and its implementation.

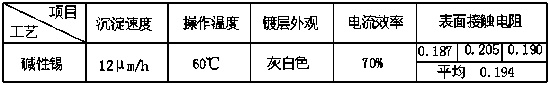

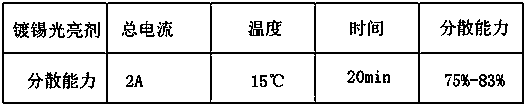

[0028] Please refer to figure 1 ,in figure 1 The experimental data table of the brightener for tin plating and its preparation method provided by the present invention; figure 2 for figure 1 Dispersing Power Data Sheet for the tinning brighteners described. A tin plating brightener, raw materials include glutaraldehyde, dihydroxypropanethiol, cinnamaldehyde, alkylphenol polyoxyethylene ether and water;

[0029] Its raw material ratio is as follows:

[0030] 55-80 parts of glutaraldehyde, 60-90 parts of dihydroxypropanethiol, 5-10 parts of cinnamaldehyde, 55-85 parts of alkylphenol polyoxyethylene ether, 300-400 parts of water.

[0031] Described glutaraldehyde is 65 parts, and dihydroxypropanethiol is 75 parts, and cinnamaldehyde is 8 parts, and alkylphenol polyoxyethylene ether is 80 parts, and through glutaraldehyde is 65 parts, and dihyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com