Reversed-polarity AlGaInP red light LED chip structure and manufacturing method thereof

A production method and reverse polarity technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of difficult main electrode ITO production and limited welding wire yield, so as to improve the welding wire yield and improve the welding efficiency. The effect of enhancing the line yield and adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

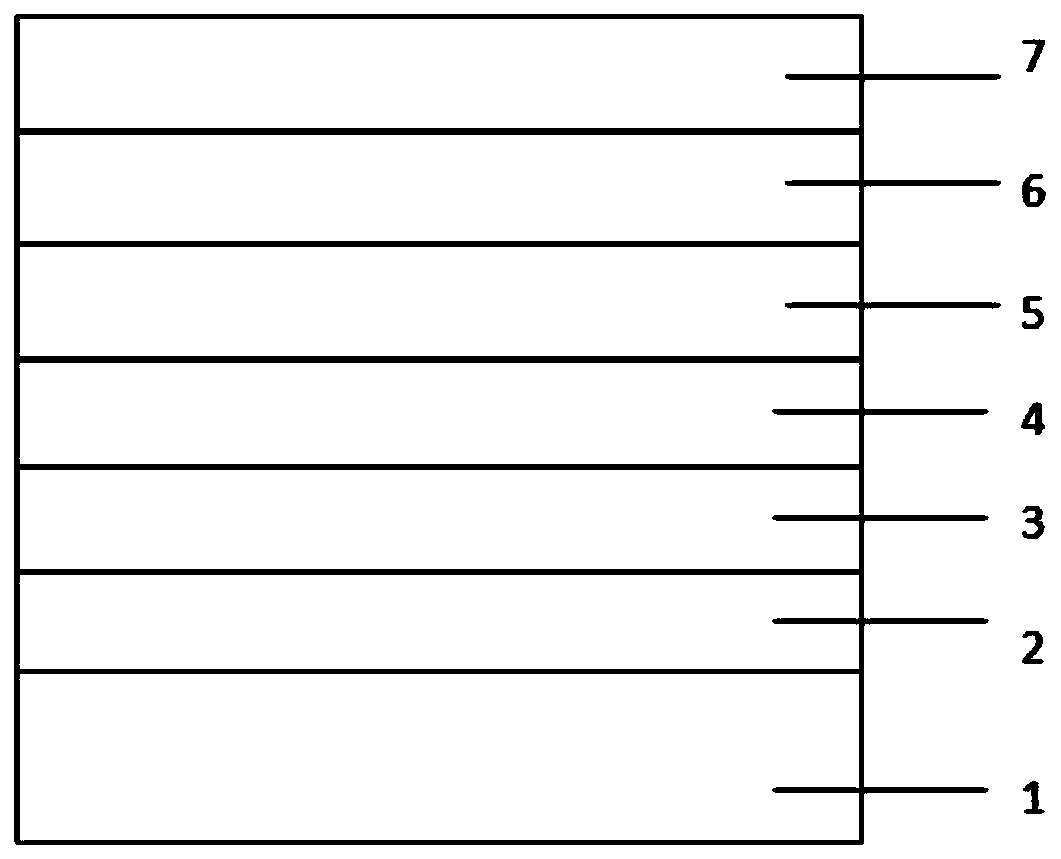

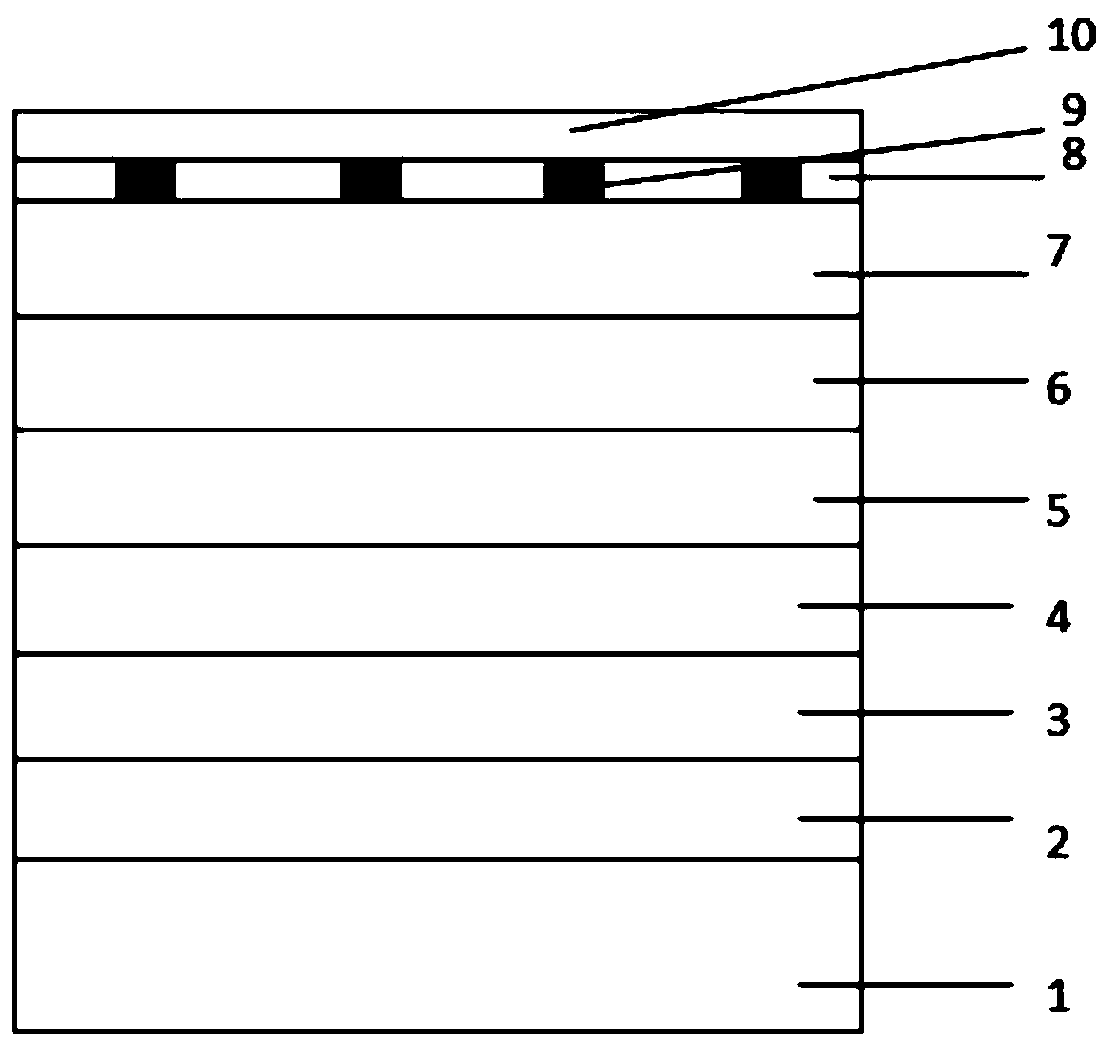

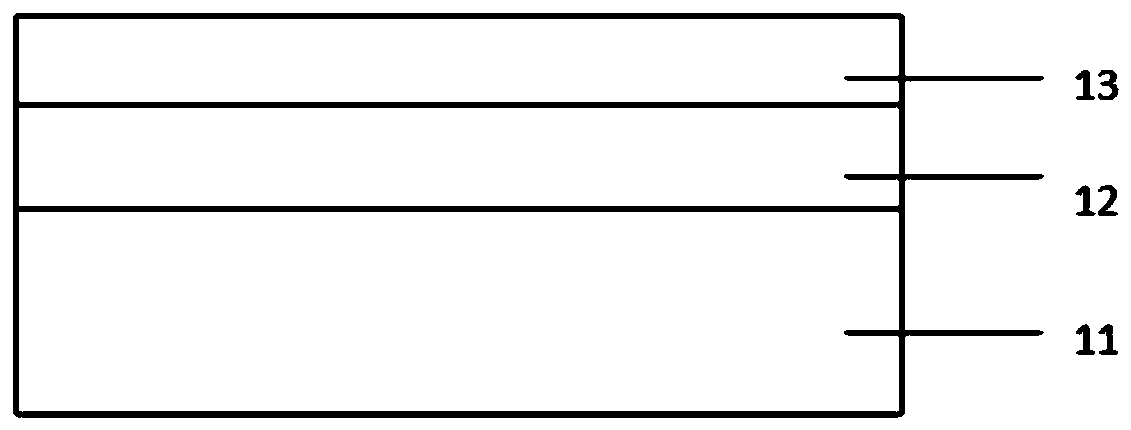

[0066] A reverse polarity AlGaInP red LED tube core structure, such as Figure 14 As shown, it includes N-face electrode 18, permanent silicon substrate 11, second mirror layer 12, metal adhesion layer 13, first mirror layer 10, SiO2 barrier layer 8 and ohmic contact layer 9 from bottom to top. , P-GaAs layer 7, P-AlGaInP layer 6, MQW quantum well layer 5, N-AlGaInP layer 4, N-GaAs layer 3 and ITO film layer 15 and SiO2 protective layer 17, extended electrode 14, main electrode 16;

[0067] The surface of the P-AlGaInP layer 6 has been roughened; the main electrode 16 is arranged on part of the ITO film layer 15; the SiO2 protection layer 17 fills the gap between the part of the ITO film layer 15 and the remaining part of the ITO film layer 15, and covers the remaining part The ITO film layer 15 and the extended electrode 14 are arranged on the N-GaAs layer 3 .

[0068] Use the ITO film layer 15 to replace the AlGaInP layer to directly contact the main electrode 16, and utili...

Embodiment 2

[0074]According to a kind of reverse polarity AlGaInP red light LED pipe core structure described in embodiment 1, its difference is that, the thickness of ITO film layer 15 is 20 angstroms;

Embodiment 3

[0076] According to a kind of reverse polarity AlGaInP red light LED pipe core structure described in embodiment 1, its difference is that, the thickness of ITO film layer 15 is 50 angstroms;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com