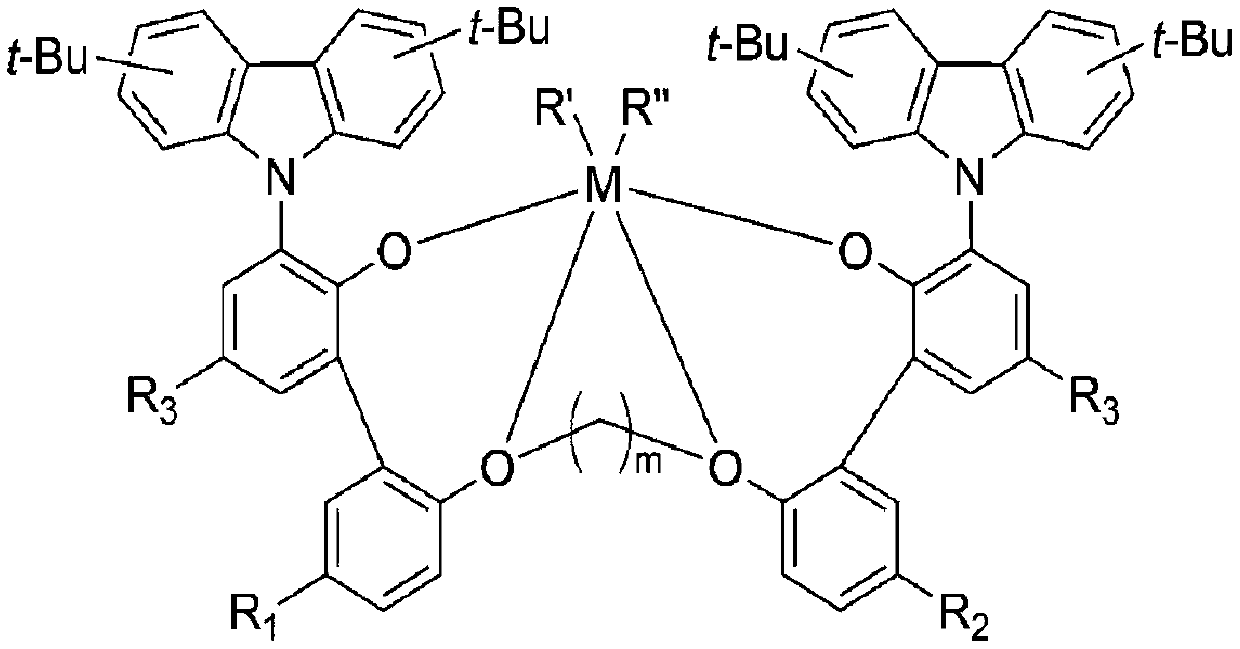

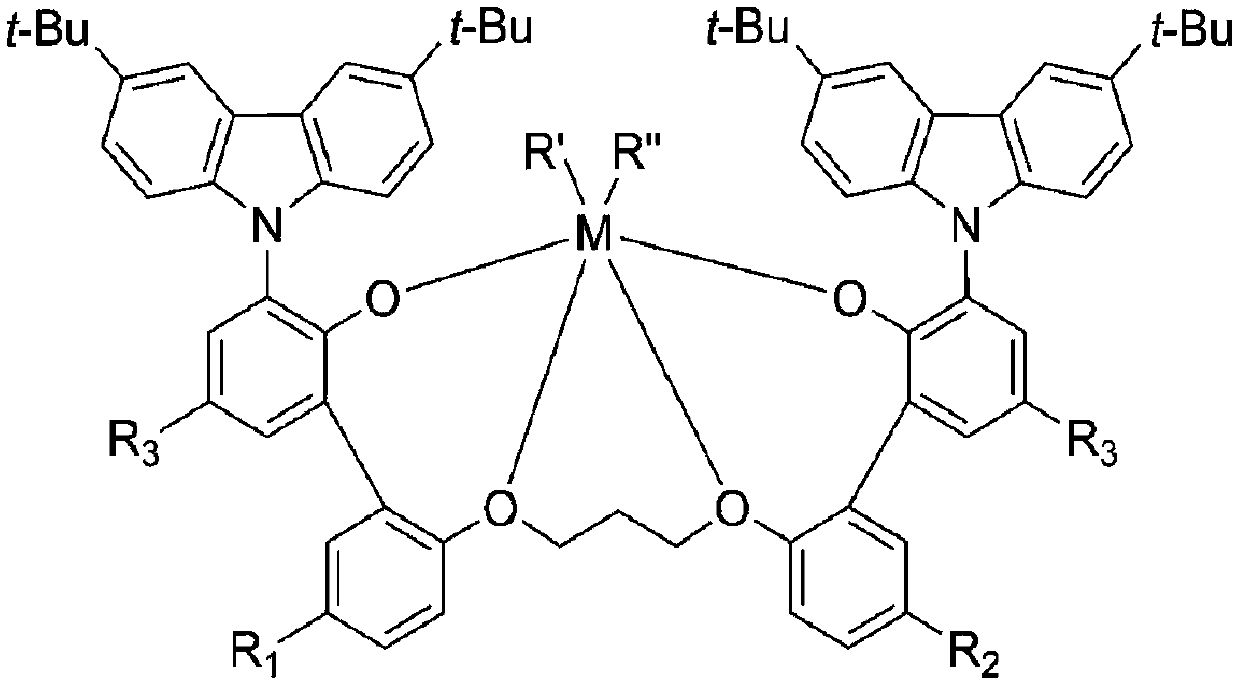

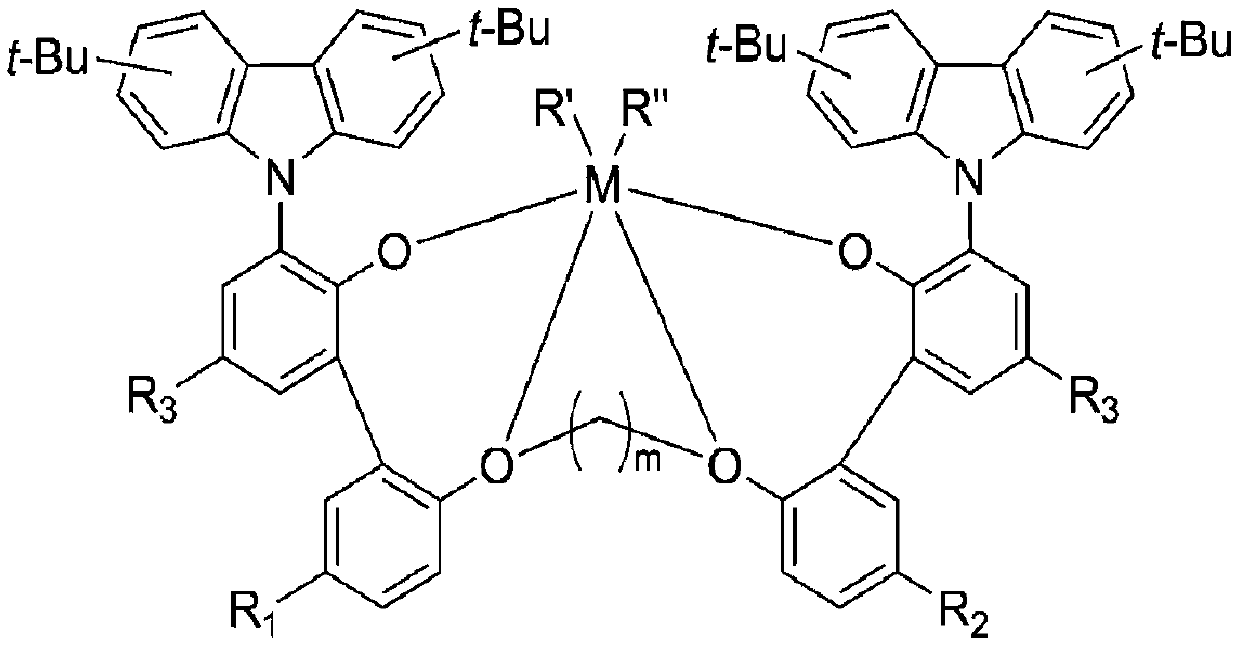

Metal-ligand complex, catalyst composition comprising same for ethylene-based polymerization, and method for preparing ethylene-based polymer by using same

一种配合物、助催化剂的技术,应用在化学仪器和方法、钛有机化合物、周期表第4/14族元素的化合物等方向,达到活性不会下降、容易聚合、反应性良好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 11

[0120] [Production Example 1] 1,3-bis(4-fluoro-2-iodophenoxy)propane (1,3-bis(4-fluoro-2-iodopheno xy) propane) (compound A) synthesis

[0121]

[0122] Synthesis of 4-Fluoro-2-iodophenol (Compound a-1)

[0123] In a round-bottomed flask, add 4-fluorophenol (4-Fluorophenol) (40mmol, 4.9g) and NaI, NaOH according to the equivalent, add MeOH (60mL) to it, utilize ice-bath (ice-bath) to adjust the temperature to 0 ℃. NaOCl (1 equiv.) was added using a Syringe pump for 1 hour. After all the NaOCl was added, it was stirred at the same temperature for 3 hours. Then, 10% sodium thiosulfate solution (30 mL) was added thereto, the pH was adjusted to 5-6 with 5% HCl solution again, and extraction was performed with diethyl ether. The extracted filtrate was separated and purified by column chromatography (eluent EA / n-Hex=1 / 30v / v) to obtain compound a-1 (5.2 g, 54%) as a light yellow solid.

[0124] 1 H NMR (CDCl 3): δ7.39(d, 1H), 7.01(m, 1H), 6.98(m, 1H), 5.10(s, 1H)

[...

Embodiment 1

[0128] [embodiment 1] the synthesis of precatalyst WCO3

[0129] Synthesis of 2-Iodo-4-octylphenol (Compound 3-1)

[0130]

[0131] In a round bottom flask, add 4-n-octylphenol (4-n-Octylphenol) (20mmol, 4.13g) and NaI (1.1eq) and NaOH (1.2eq), add MeOH (120mL) to it, use ice bath (ice-bath) Adjust the temperature to 0°C. NaOCl (1 equivalent) was slowly added thereto using a syringe pump over 1 hour, followed by further stirring at the same temperature for 3 hours. After adding 10% sodium thiosulfate solution (30 mL), adjust the pH to 5-6 with 5% HCl solution, and extract with diethyl ether. After removing the solvent from the extracted filtrate, the compound 3-1 (2.9 g, 65%) was obtained as a colorless liquid by column chromatography (eluent: EA / n-Hex = 1 / 30 v / v).

[0132] 2-(2-iodo-4-octylphenoxy)tetrahydro-2H-pyran (2-(2-iodo-4-octylphenoxy)tetrah ydro-2H-pyran) (compound 3-2) synthesis

[0133]

[0134] In a round bottom flask, add compound 3-1 and p-TsOH (...

Embodiment 2

[0153] [embodiment 2] the synthesis of precatalyst WCO4

[0154] Synthesis of 2-Iodo-4-dodecylphenol (Compound 4-1)

[0155]

[0156] In a round bottom flask, add 4-n-dodecylphenol (4-n-Dodecylphenol) (40mmol, 10.5g) and NaI (1.1eq) and NaOH (1.2eq), add MeOH (120mL) thereto, use An ice-bath was used to adjust the temperature to 0 °C. After NaOCl (1 equivalent) was slowly added thereto using a syringe pump (Syringe pump) over 1 hour, it was further stirred at the same temperature for 3 hours. Then, after adding 10% sodium thiosulfate solution (30 mL), the pH was adjusted to 5-6 with 6.5% HCl solution again, and extracted with diethyl ether. The extracted filtrate was separated and purified by column chromatography (eluent: EA / n-Hex=1 / 30v / v) to obtain compound 4-1 (8 g, 65%) in the form of a colorless liquid.

[0157] 2-(2-iodo-4-dodecylphenoxy)tetrahydro-2H-pyran (2-(2-iodo-4-dodecylphenoxy) tetrahydro-2H-pyran) (compound 4-2) synthesis

[0158]

[0159] In a r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| molecular weight over number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com