Continuous nitration reaction system and continuous nitration process of methyl benzoic acid

A technology of toluic acid and nitrification system, applied in the field of continuous nitrification process, can solve the problems of low production efficiency, high energy consumption, complicated operation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

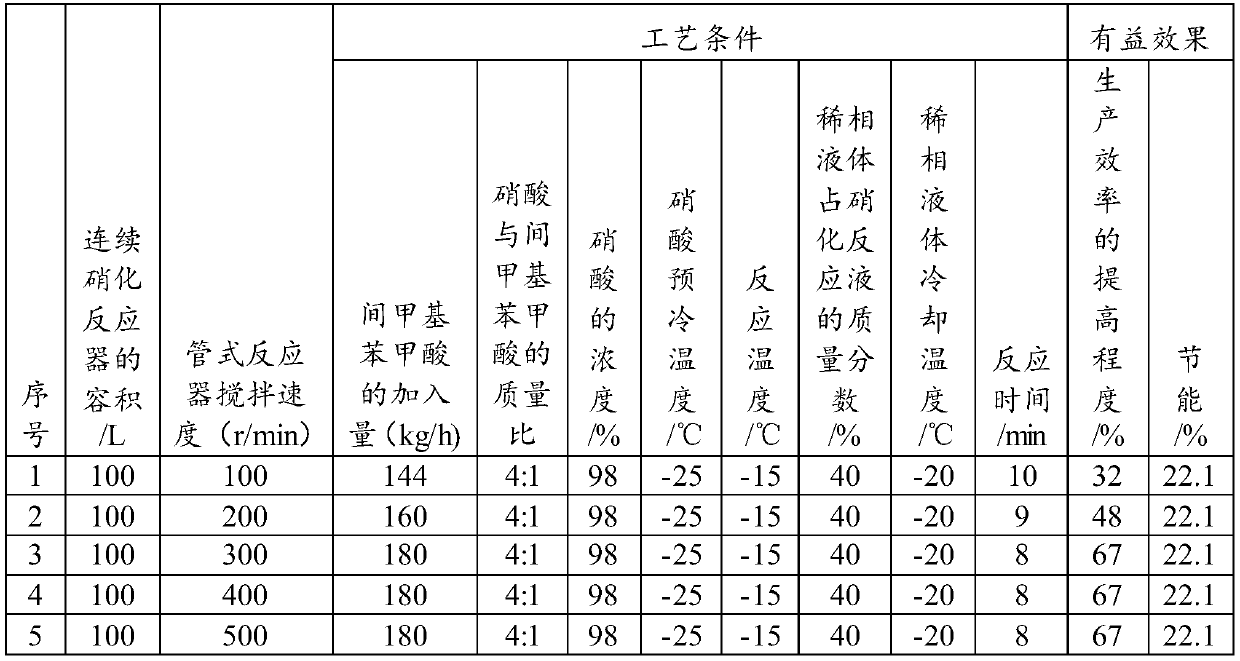

Examples

Embodiment 1

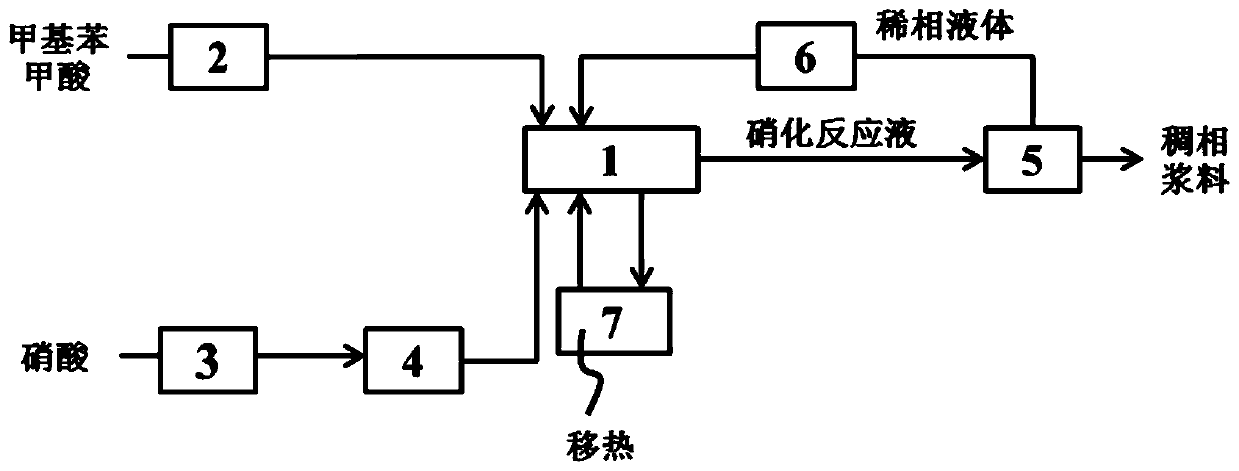

[0095] The outlet of the solid continuous feeding system (2) is connected with the first material inlet of the continuous nitration reactor (1), the outlet of the liquid continuous feeding system (3) is connected with the material inlet of the liquid cooler (4), and the liquid cooler (4) ) is connected to the second material inlet of the continuous nitration reactor (1), the material outlet of the continuous nitration reactor (1) is connected to the inlet of the reaction solution thickener (5), and the reaction solution thickener (5) The outlet of the clear liquid is connected with the material inlet of the circulating liquid condenser (6), the material outlet of the circulating liquid condenser (6) is connected with the third material inlet of the continuous nitration reactor (1), and the refrigerant outlet of the refrigerant system (7) It is connected with the refrigerant inlet of the continuous nitration reactor (1), and the refrigerant return port of the refrigerant system ...

Embodiment 2

[0101] The difference between embodiment 2 and embodiment 1 is that the continuous nitration reactor (1) selected is a tubular reactor with a rod-shaped stirring structure with a volume of 100 L, and the connection mode of the equipment and the inlet position of the material are all the same as in embodiment 1.

[0102] Use the continuous nitration reaction system of toluic acid to carry out the continuous nitration reaction of o-toluic acid:

[0103] The o-toluic acid is continuously transported at a flow rate of 150kg / h through the solid continuous feeding system (2), and enters the continuous nitration reactor (1) from the first material inlet, and at the same time, the nitric acid with a concentration of 98% is continuously fed from the liquid The system (3) conveys the continuous flow through the liquid raw material cooler (4) to be precooled to 18°C lower than the reaction temperature, i.e. -30°C, and enters the continuous nitration reactor (1) from the second material ...

Embodiment 3

[0106] The difference between embodiment 3 and embodiment 1 is that the continuous nitration reactor (1) selected is a tubular reactor with a plug-in mixing structure with a volume of 100 L, and the connection mode of the equipment and the inlet position of the material are all the same as those in embodiment 1. same.

[0107] Use the continuous nitration reaction system of toluic acid to carry out the continuous nitration reaction of p-toluic acid:

[0108] P-benzoic acid is continuously transported at a flow rate of 140kg / h through the solid continuous feeding system (2), and enters the continuous nitration reactor (1) from the first material inlet, and simultaneously the nitric acid with a concentration of 98% is fed from the liquid continuous feeding system (3) Convey and flow through the liquid raw material cooler (4) to be pre-cooled to 20 ℃ lower than the reaction temperature, i.e. -30 ℃, enter the continuous nitration reactor (1) by the second material inlet, the quali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com