A kind of tb9 titanium alloy wire rod and manufacturing method thereof

A technology of titanium alloy wire and its production method, which is applied in the field of titanium alloy processing, can solve problems such as accumulated chipping, large deformation resistance, and increased wire drawing resistance, and achieve the effects of uniform structure, uniform cross-sectional performance, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

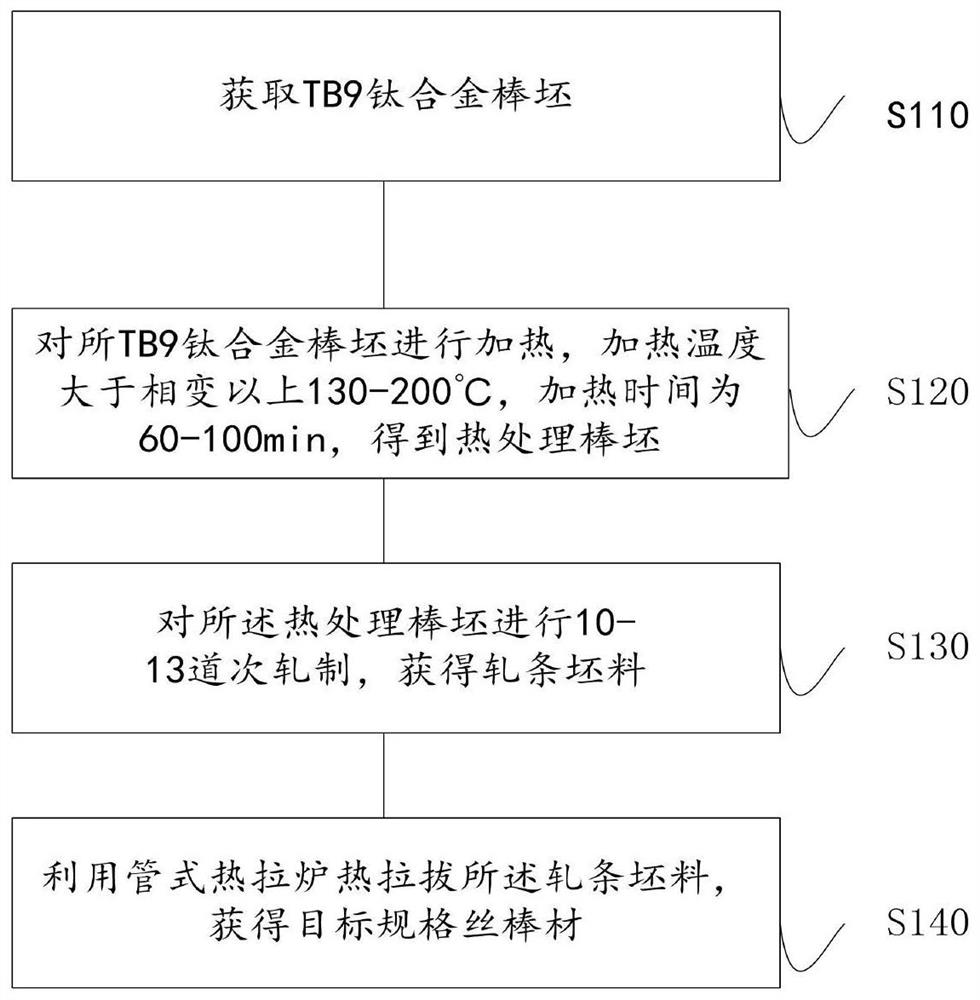

[0029] See figure 1 . The embodiment of the present invention provides a kind of manufacturing method of TB9 titanium alloy wire rod, comprises the following steps:

[0030] S110. Obtain a TB9 titanium alloy billet.

[0031] S120. Heating the TB9 titanium alloy billet, the rolling heating temperature is 130-200° C. above the phase transformation, and the heating time is 60-100 min, to obtain a heat-treated billet.

[0032] Specifically, heating at 130°C to 200°C above the phase transition point can homogenize the structure of the rolled billet and make the structure of each part uniform. At this temperature, the structure of the TB9 titanium alloy is a β-phase structure, and the deformation resistance is small, which is conducive to deformation. Processing, and reasonable heating time control can avoid excessive grain growth.

[0033] S130. Rolling the heat-treated billet for 10-13 passes to obtain a rolled billet.

[0034] S140. Using a tubular hot-drawing furnace to hot-...

Embodiment 2

[0046] The composition of TB9 titanium alloy is: Al: 3%-4%, V: 7.5%-8.5%, Cr: 5.5%-6.5%, Mo: 3.5%-4.5%, Zr: 3.5%-4.5%, and the balance is Ti.

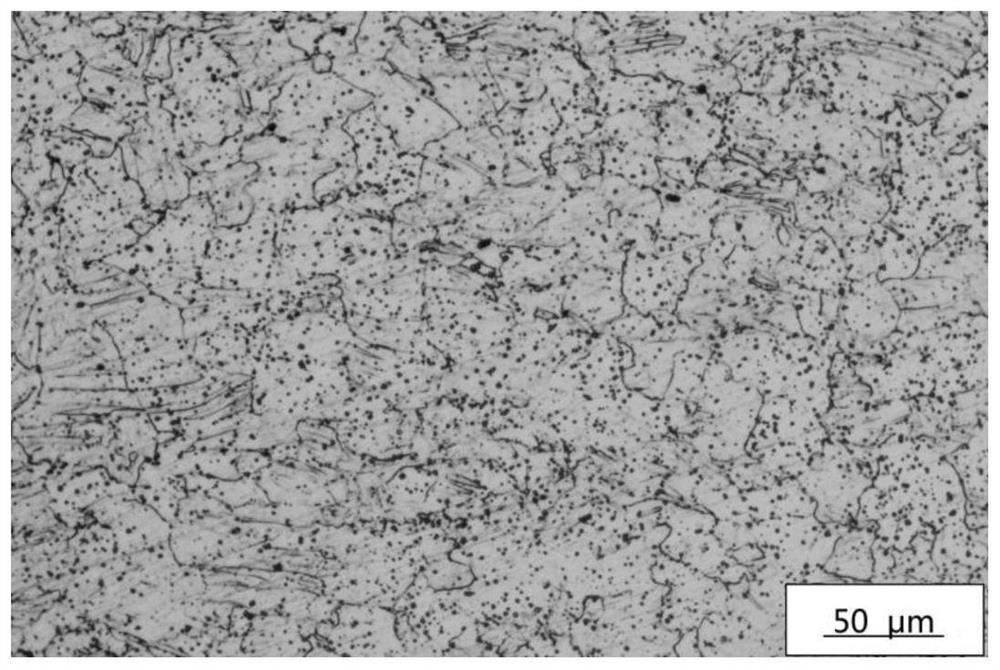

[0047] Step 1. Select a TB9 titanium alloy billet with a specification of Φ70mm, place it in a box-type resistance furnace, heat it at 200°C above the phase transition point, keep the furnace for 100min, and roll it to Φ13.5mm in 13 passes. The amount of deformation in each pass is 8% to 25%.

[0048] Step 2, heating the strip blank obtained by rolling in step 1 in a tubular hot-drawing furnace, the heating temperature is selected at 60-90°C above the phase transition point, the heating method is continuous-pass heating, and the drawing line speed is 2.5 ~4m / min, 9 passes of hot drawing to Φ8mm, the deformation of each pass is 13%~18%.

[0049] Step 3, heating the wire and rod material that has been hot-drawn in step 2 in a tubular hot-drawing furnace for on-line heat treatment to obtain the TB9 titanium alloy rod and wire material o...

Embodiment 3

[0053] The composition of TB9 titanium alloy is: Al: 3%-4%, V: 7.5%-8.5%, Cr: 5.5%-6.5%, Mo: 3.5%-4.5%, Zr: 3.5%-4.5%, and the balance is Ti.

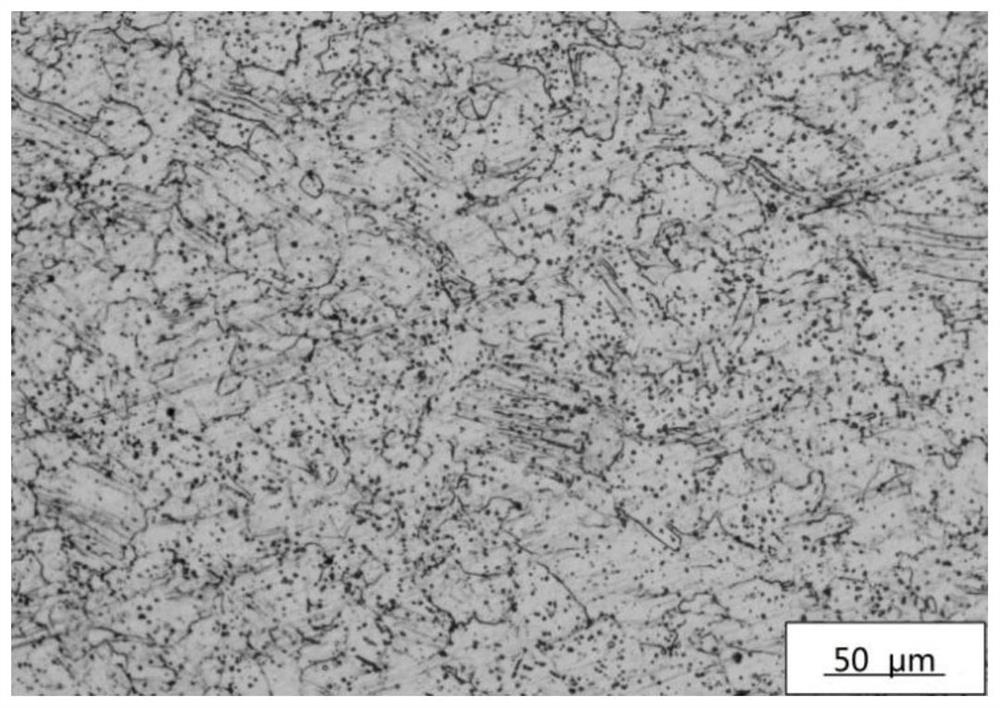

[0054] Step 1. Select a TB9 titanium alloy billet with a specification of Φ60mm, place it in a box-type resistance furnace, heat it at 150°C above the phase transition point, keep it in the furnace for 80min, and roll it to Φ10.5mm in 12 passes. The amount of deformation in each pass is 8% to 25%.

[0055] Step 2, heating the strip blank obtained by rolling in step 1 in a tubular hot-drawing furnace, the heating temperature is selected at 40-70°C above the phase transition point, the heating method is continuous-pass heating, and the drawing line speed is 1.5 ~3m / min, 9 passes of hot drawing to Φ6mm, the deformation of each pass is 9%~14%.

[0056] Step 3, heating the wire and rod material that has been hot-drawn in step 2 in a tubular hot-drawing furnace for on-line heat treatment to obtain the TB9 titanium alloy rod and wire materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com