Chlorinated waste residue resource utilization method

A technology of recycling chlorinated waste slag, which is applied in the field of resource utilization of chlorinated waste slag, can solve the problem of high metal content and achieve the effect of facilitating precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

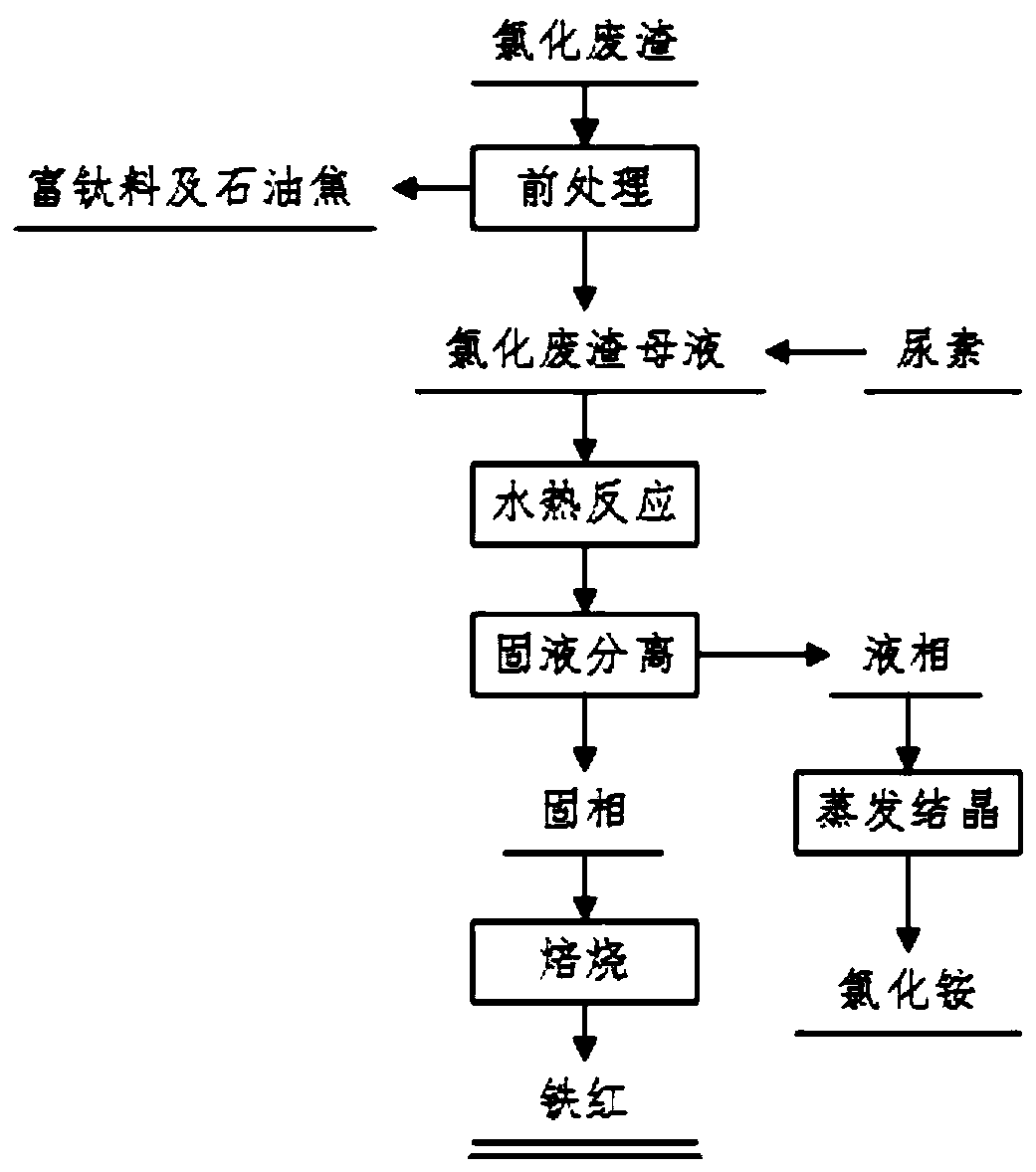

Method used

Image

Examples

Embodiment Construction

[0033]In the following, the present invention will be further described in conjunction with the experiment. According to the mass ratio of chlorination waste residue to water is 1:3, the slurry is carried out, then the titanium-rich material and petroleum coke are removed by filtration, and the mother liquor of chlorination waste residue is obtained, and the composition of the obtained chlorination waste residue mother liquor is detected. , the results are shown in Table 1:

[0034] Table 1

[0035] Element FeCl 2 / FeCl 3

VOCl 3

MgCl 2

AlCl 3

other pH content / % 15.8 0.23 2.25 5.32 2.53 0.73

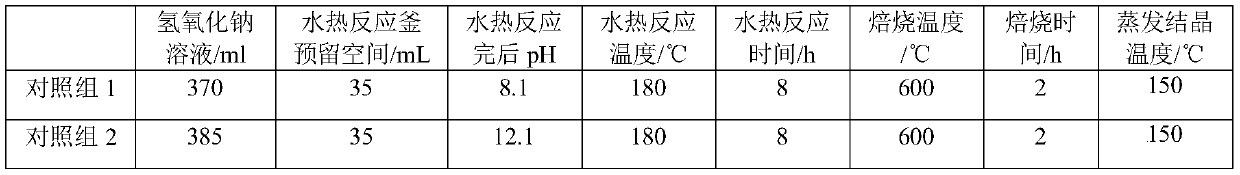

[0036] The specific steps of the experiment are as follows: Each experimental group takes 400ml of the chlorinated waste residue mother liquor, adds urea of different qualities, and the addition amount is shown in Table 2, stirs at 100r / min for 30min, and puts it into a 250mL hydrothermal reaction kettle after stirring; The amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com