Preparation method for modified phenolic resin electrode materials

A technology of phenolic resin and electrode materials, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of difficult polymer dispersion, low reactivity, and easy agglomeration, and achieve good stability, improve dispersion, and reduce agglomeration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Preparation of the working electrode: mix the electrode material, carbon black and binder of the present invention with N-methylpyrrolidone evenly, apply it on the platinum electrode and dry it, and then test it on the CHI660D electrochemical workstation.

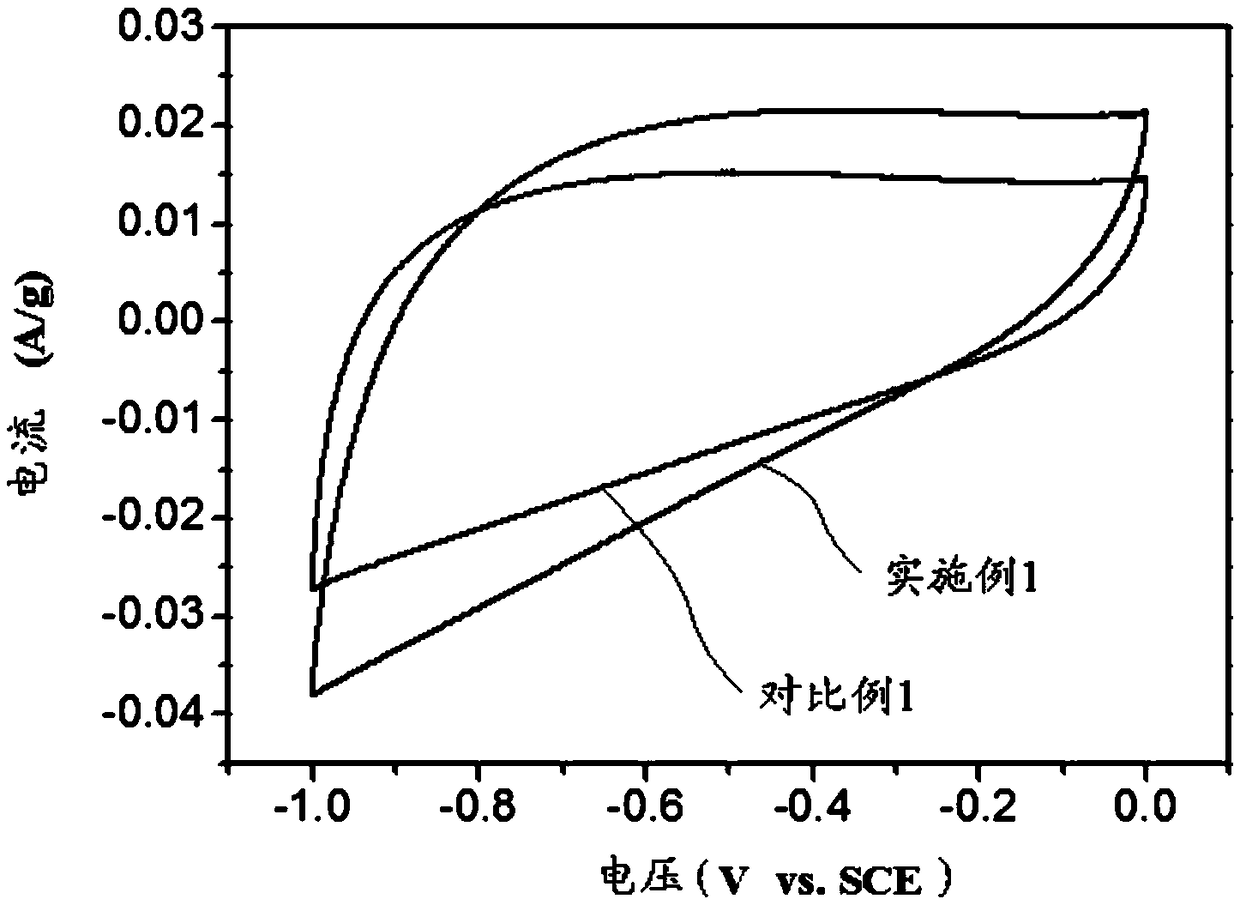

[0027] Cyclic voltammetry curve: room temperature, 6mol / L KOH electrolyte, scanning voltage -0.2~0.4V.

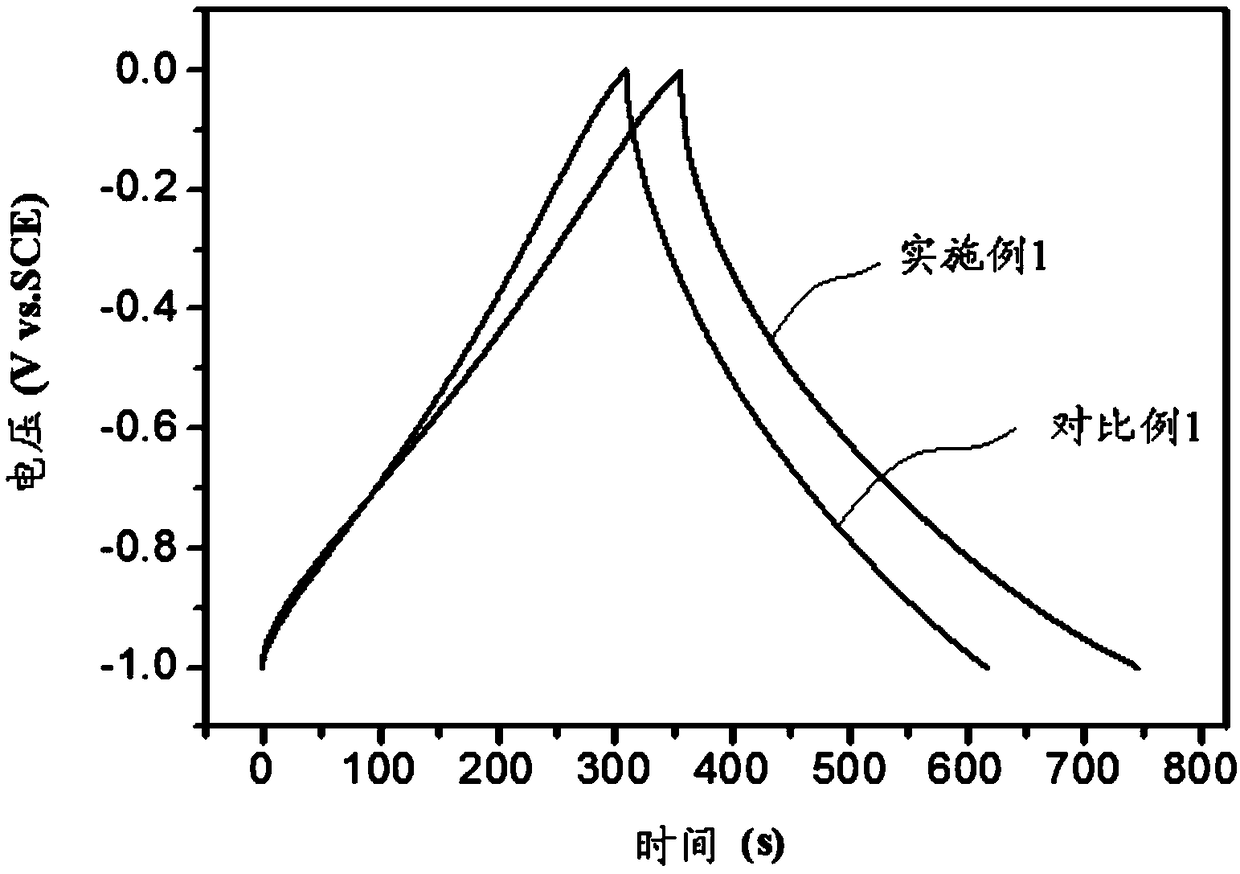

[0028] Constant current discharge curve: at room temperature, the current density is 1.0A / g.

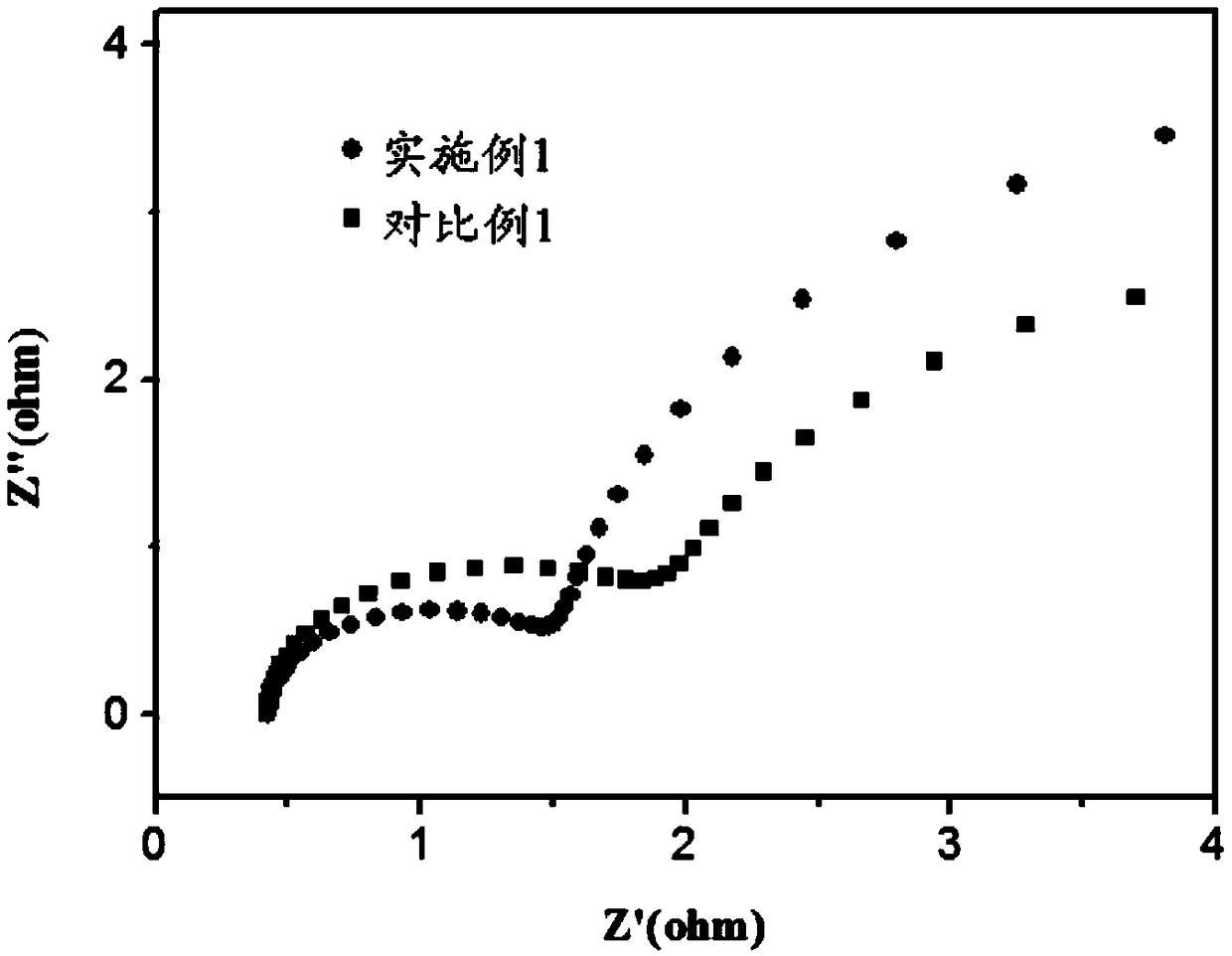

[0029] AC impedance spectroscopy: at room temperature, a standard saturated Ag / AgCl electrode is used as a reference electrode, the glassy carbon electrode whose surface is coated with the electrode material of the present invention is used as a working electrode, and a platinum electrode is used as a counter electrode, the KOH electrolyte of 6mol / L, and the voltage is 0.4V, the frequency range is 0.01Hz ~ 100kHz.

Embodiment 1

[0031] (1) Under stirring, according to the weight ratio of phenol and formaldehyde is 1:1.2, formaldehyde is added to the phenol after melting, then add graphene oxide of 0.8wt% of phenol weight, stir 10~60min, then add phenol 0.8wt% ammonia water by weight to obtain the first solution.

[0032] (2) The temperature of the first solution was raised to 80° C. in 90 minutes, and to 95° C. in 30 minutes, and then kept for 40 minutes to obtain the second solution.

[0033] (3) Cool the second solution immediately. When the temperature of the solution drops to 80°C, start dehydration under reduced pressure. When the temperature of the solution drops to 60°C, start heating to keep the second solution in an azeotropic state. 90°C, when the gel time at 150°C reaches 100s, stop dehydration to obtain modified phenolic resin.

[0034] (4) The temperature of the modified phenolic resin was raised to 1000° C. at 6° C. / min under the protection of an inert gas, kept at a temperature of 4 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com