Wastewater treatment system capable of realizing acid recycling

A wastewater treatment system and technology of the treatment system, applied in textile industry wastewater treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of increasing the cost of flue gas treatment to meet the standard discharge pressure and the increase of effluent salinity , content increase and other issues, to achieve the effect of reducing infrastructure investment, short circulation path, and compact design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The wastewater treatment system for acid circulation recovery of the present invention will be described in detail below in conjunction with the accompanying drawings.

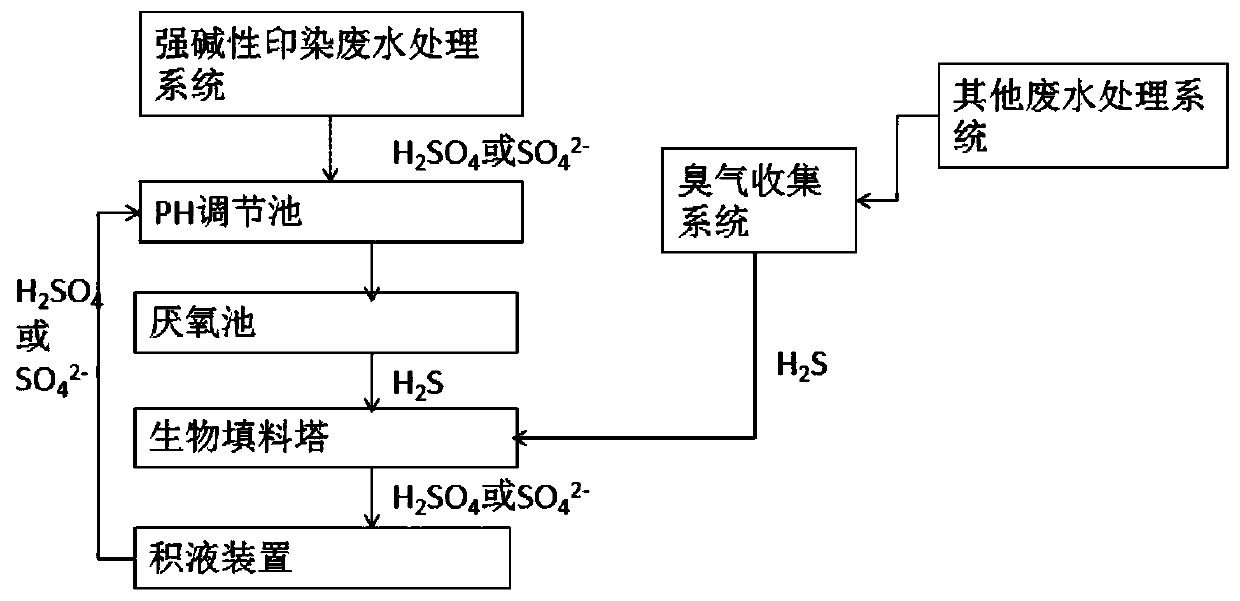

[0015] Such as figure 1 Shown, a kind of waste water treatment system of acid cycle recovery of the present invention comprises strong alkaline printing and dyeing wastewater treatment system and odor collection device and biological packing tower, wherein strong alkaline printing and dyeing wastewater treatment system includes pH adjustment pool, is used for adjusting The pH value of the strong alkaline printing and dyeing wastewater, the odor collection device is used to collect the strong alkaline printing and dyeing wastewater treatment system, other sewage treatment systems and the environment, the strong alkaline printing and dyeing wastewater treatment system includes anaerobic pool, the anaerobic pool is used to biodegrade the polymers in the wastewater, and the biological packing tower is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com