Continuous solution polymerization device based on LCST and continuous solution polymerization method by adopting continuous solution polymerization device

A technology of a polymerization device and a polymerization method, which is applied in the production of bulk chemicals, etc., can solve the problems of a large amount of energy consumption, polymerization and even explosion, and increase in reactivity, and achieve the effect of low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

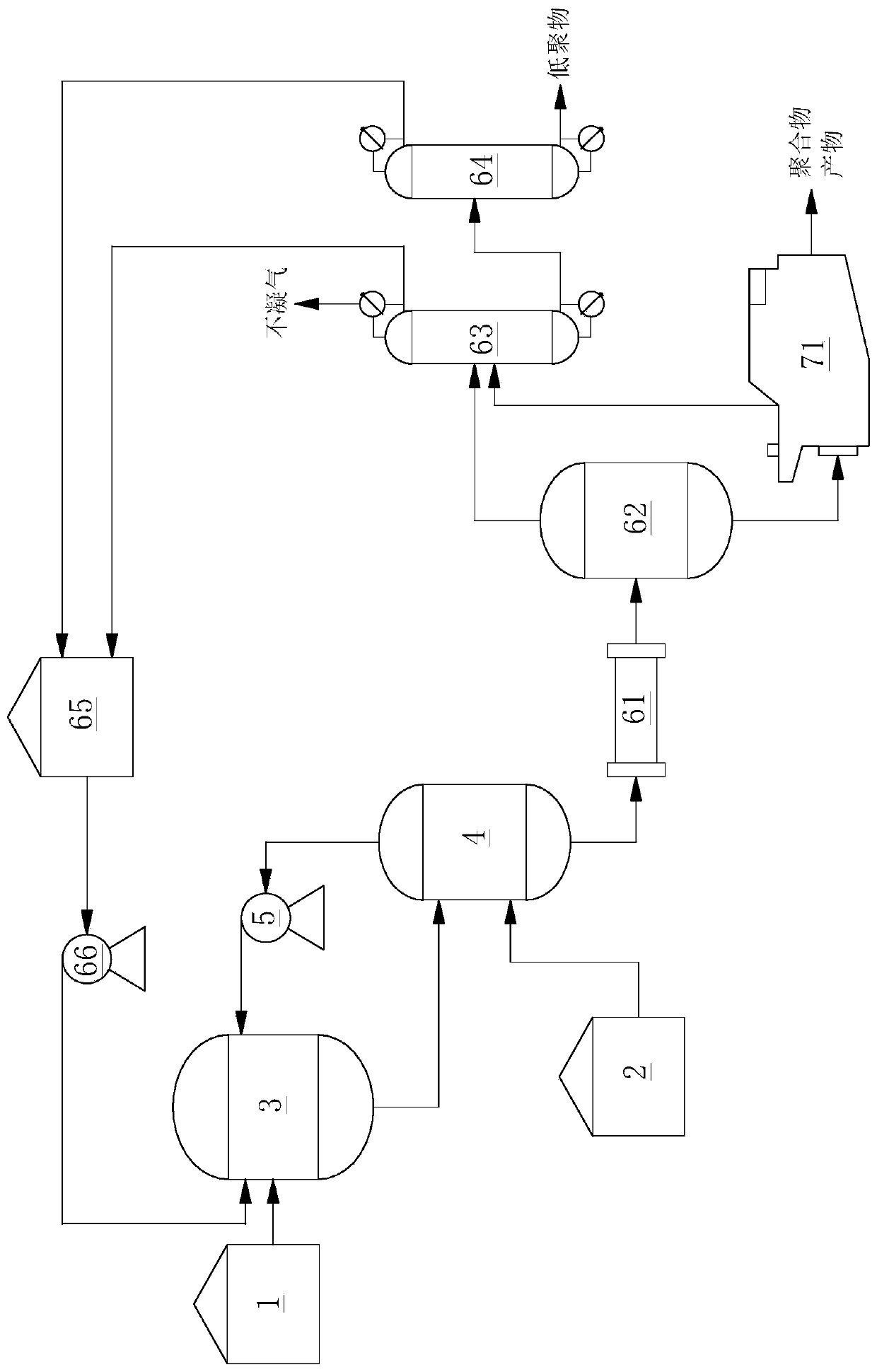

[0059] Such as figure 1 Shown is the first preferred embodiment of the LCST-based continuous solution polymerization device of the present invention. The continuous solution polymerization device is characterized by comprising a raw material storage tank 1, a supercritical fluid storage tank 2, a reactor 3, a liquid-liquid separation tank 4, a first booster pump 5 and a subsequent treatment system.

[0060] Wherein, the raw material storage tank 1 is used for storing reaction raw materials.

[0061] The supercritical fluid storage tank 2 is used for storing supercritical fluid.

[0062] The first material inlet of the reactor 3 is connected to the material outlet of the raw material storage tank 1, and is used for polymerizing reaction raw materials to generate a polymer solution including solvent, polymer and monomer.

[0063] The first material inlet of the liquid-liquid separation tank 4 is connected to the material outlet of the reactor 3, and the second material inlet i...

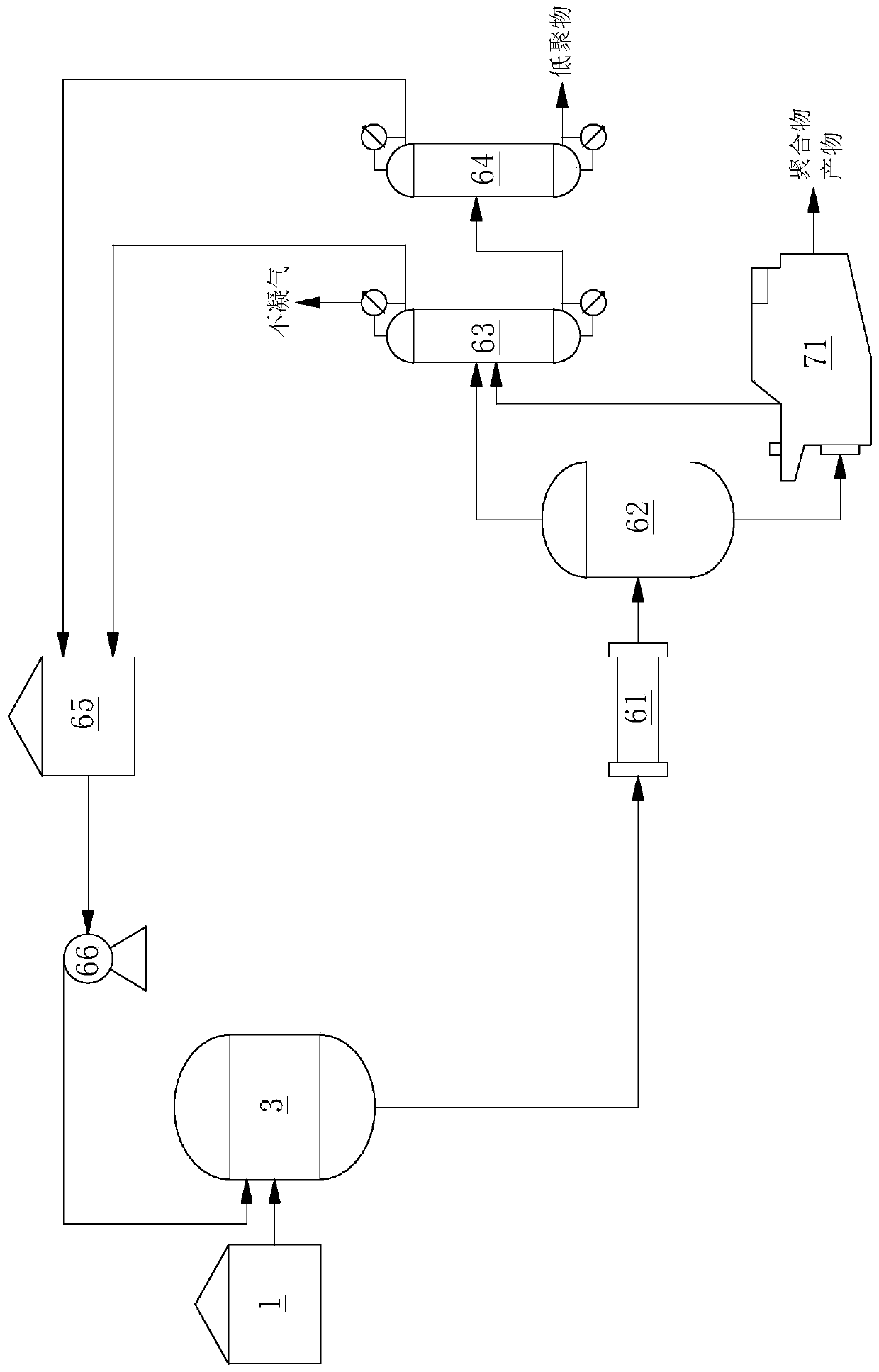

Embodiment 2

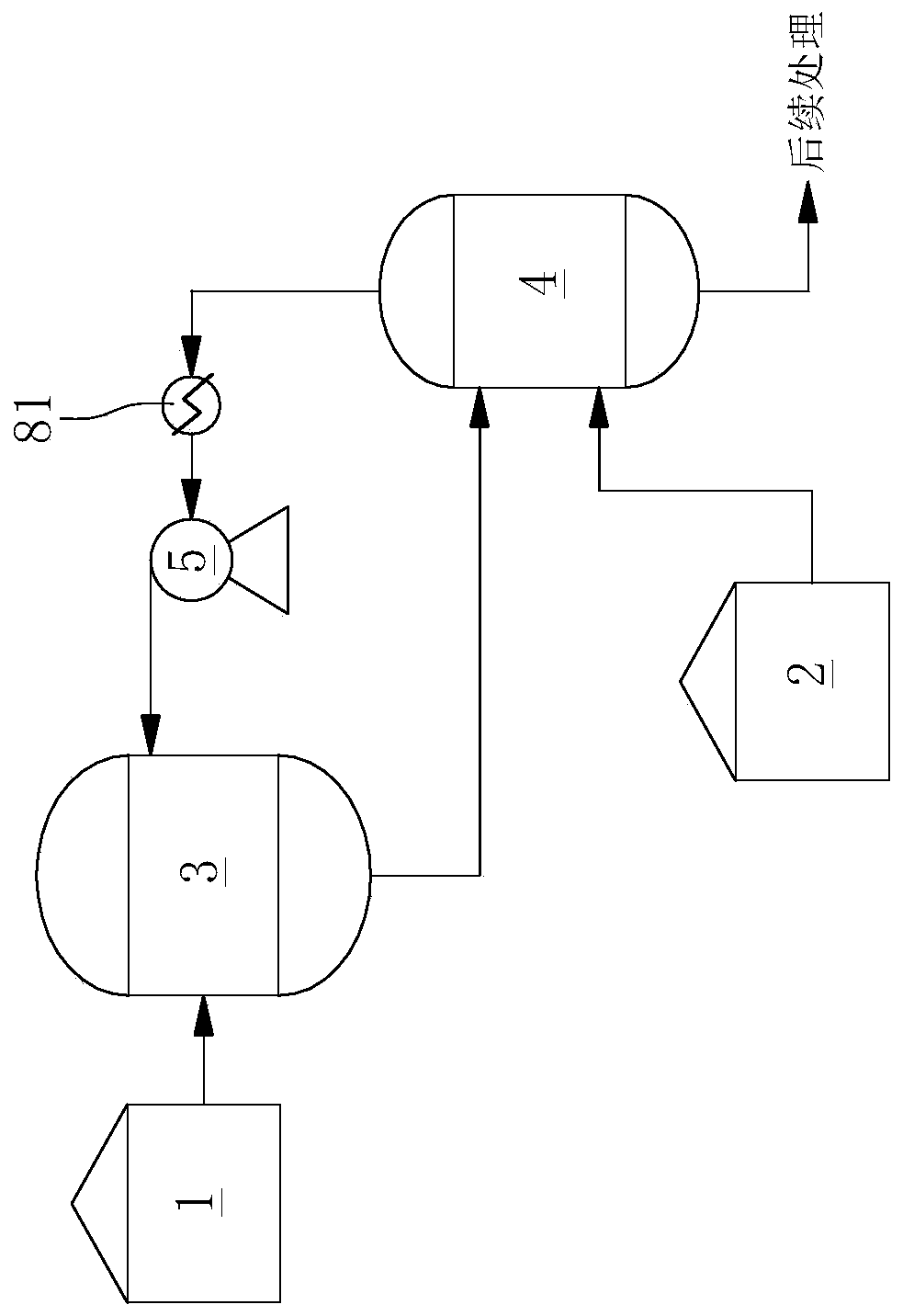

[0092] Such as image 3 Shown is the second preferred embodiment of the LCST-based continuous solution polymerization device of the present invention. The difference with Embodiment 1 is that in this embodiment, the comonomer is 1-octene, and a first heat exchanger 81 is added between the liquid-liquid separation tank 4 and the first booster pump 5 for Remove the heat of reaction.

Embodiment 3

[0108] Such as Figure 5 Shown is the third preferred embodiment of the LCST-based continuous solution polymerization device of the present invention. The difference with embodiment 1 is:

[0109] In this embodiment, at least one second gas-liquid separation tank 9 is provided between the raw material storage tank 1 and the reactor 3, and the gas phase outlet of the second gas-liquid separation tank 9 is connected to the reactor 3 through a compressor 91. The liquid phase outlet of the two gas-liquid separation tanks 9 is connected with the reactor 3 by the third booster pump 92, and the gas phase outlet of the reactor 3 is connected with the second gas-liquid separation tank 9 by the fourth heat exchanger 93, and the fourth The heat exchanger 93 is used to remove the heat of reaction.

[0110] In addition, a catalyst configuration unit 10 is added between the top outlet of the second rectification column 64 and the reactor 3 .

[0111] The present invention also provides a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com