Microfluidic PCR chip

A microfluidic and chip technology, applied in the field of microfluidic PCR chip and microfluidic, can solve the problems of complex structure, large volume, limited temperature control response, etc., and achieve high transparency, good compatibility, accurate and fast temperature control and the detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

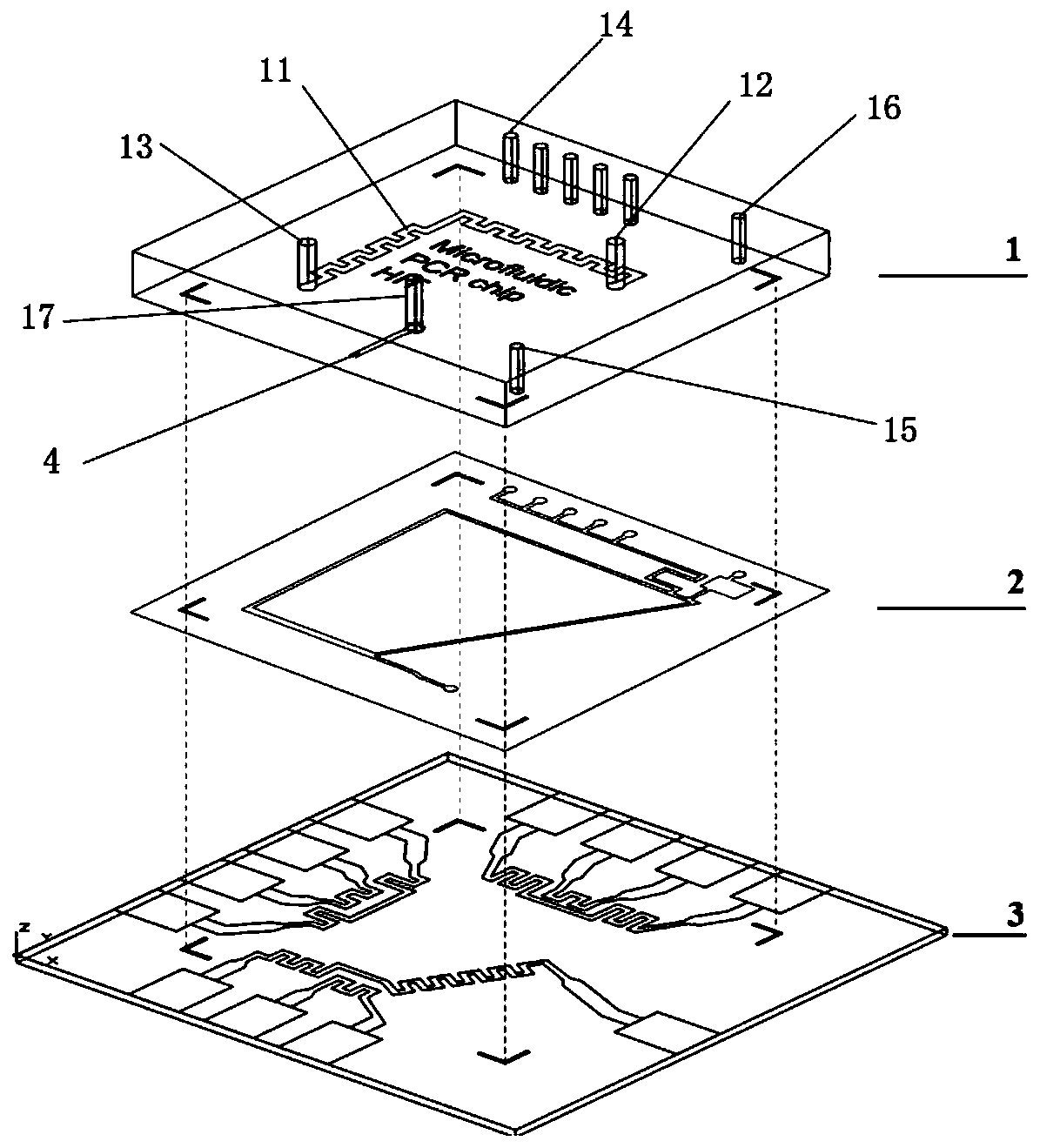

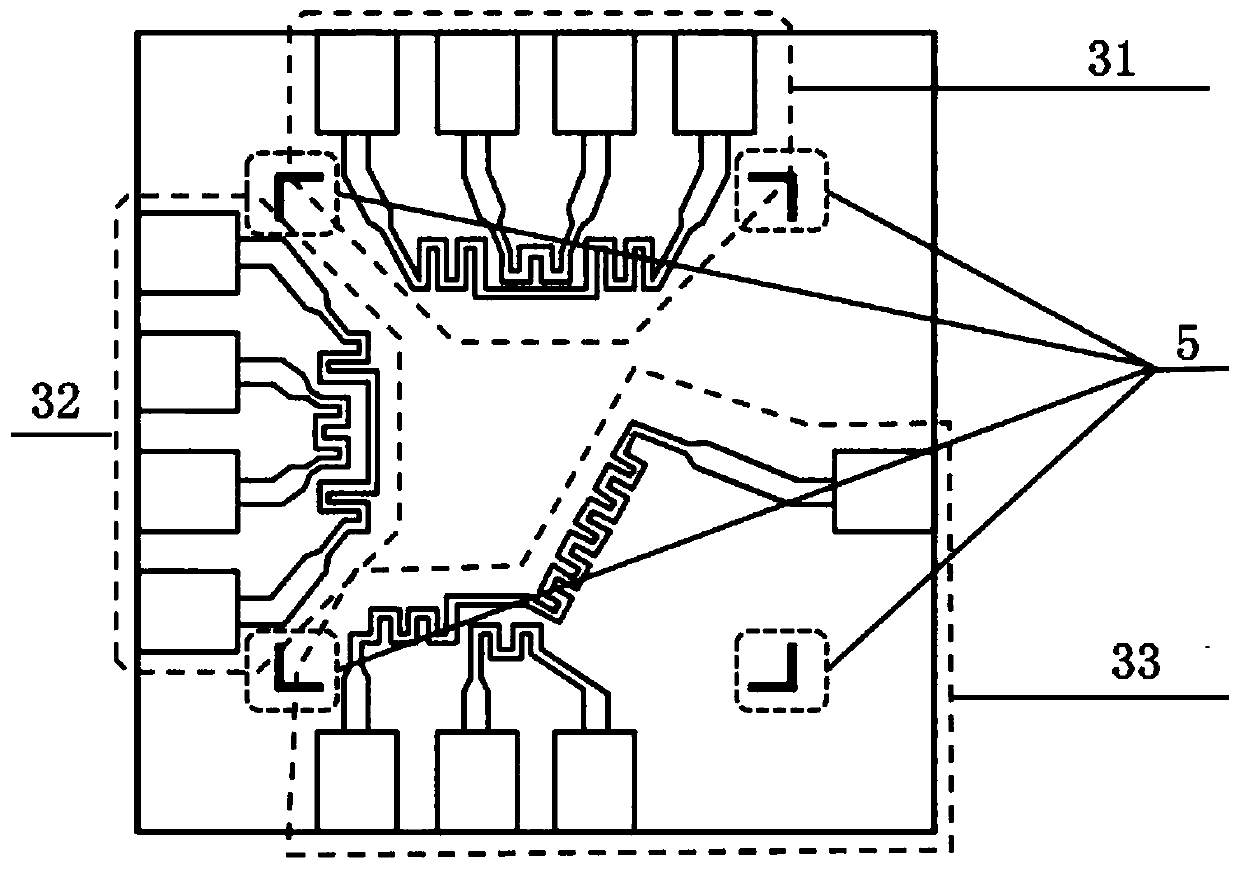

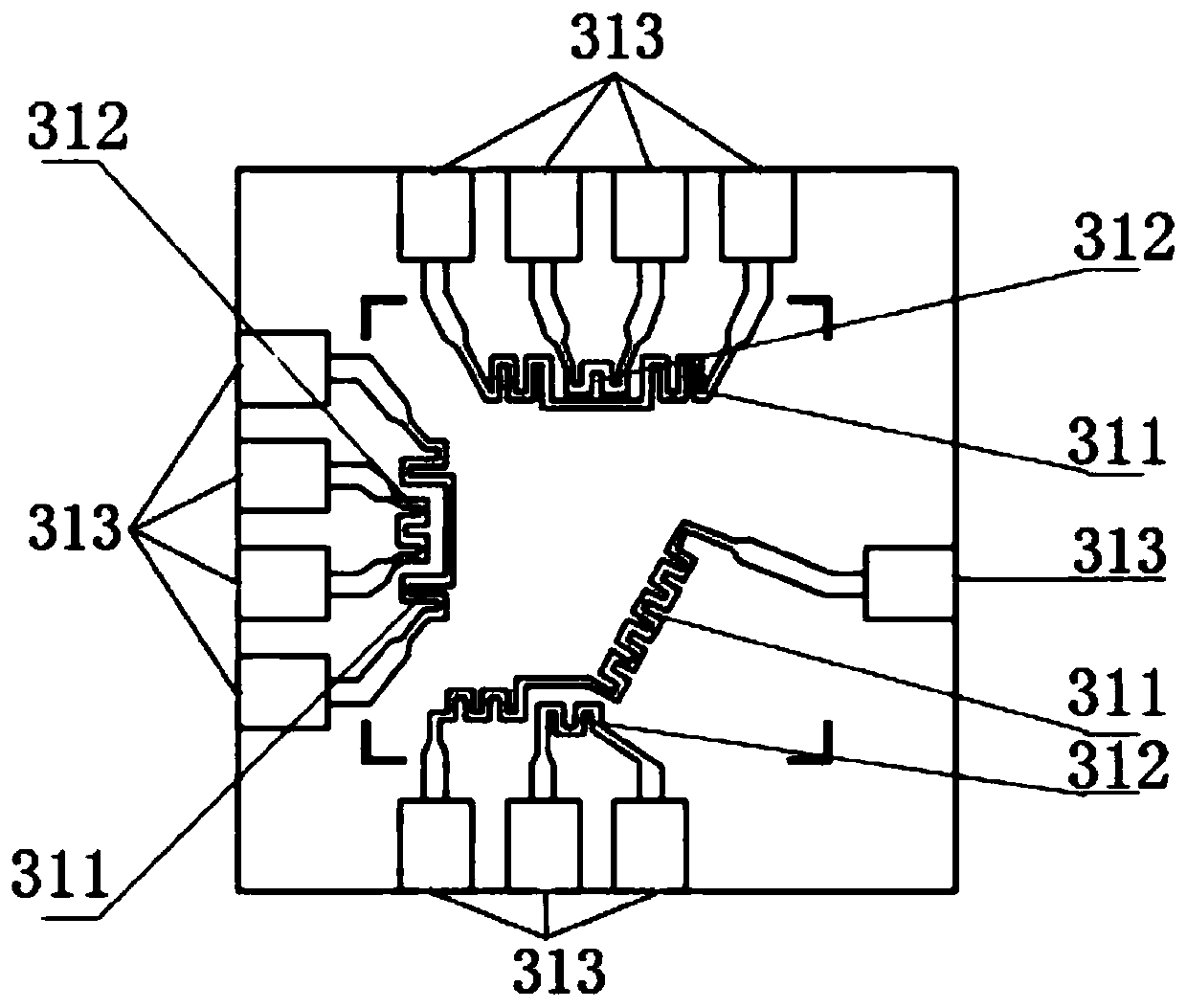

[0026] A microfluidic PCR chip, which is an on-chip temperature-controlled, temperature-difference-driven microfluidic PCR chip, comprising an integrated control cooling plate 1, a microfluidic reaction plate 2, and a temperature control plate 3. The microfluidic The reaction plate 2 is arranged between the control cooling plate 1 and the temperature control plate 3. The lower surface of the microfluidic reaction plate 2 is provided with a feed channel 21, a mixing channel 22, a pressure balance channel 23, and an annular circulation channel. 24 and a discharge flow channel 25, the feed flow channel 21 is in communication with one end of the mixing flow channel 22, and the other end of the mixing flow channel 22, the pressure balance flow channel 23 and the discharge flow channel 25 are all connected with the annular circulating flow The channel 24 is in communication, the feed channel 21, the mixing channel 22 and the pressure balance channel 23 are all located at the upper par...

specific Embodiment approach 2

[0037] The difference between this embodiment and the first embodiment is that the three parts of the annealing temperature control unit 31, the extension temperature control unit 32 and the denaturation temperature control unit 33 are at the same temperature, and the liquid position in the PCR cycle is unchanged. The reaction reagent selects the raw materials required for constant temperature PCR. Others are the same as the first embodiment.

specific Embodiment approach 3

[0039] This embodiment is different from the first embodiment in that the temperature of the annealing temperature control unit 31, the extension temperature control unit 32 and the denaturation temperature control unit 33 are the same, and the temperature of all heating elements is controlled synchronously in accordance with the denaturation, annealing, and extension Sequence loop. The liquid position does not change in the PCR cycle. Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com