Environmental-friendly ecological vehicle leather process with low total volatile organic compounds (TVOC) and low odor

A low odor, leather technology for leather making, leather softening, leather drying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Jasmine Black

[0044] S1. Skin sorting

[0045] According to the leather surface disability standard, the raw leather blanks are screened, and the leather that meets the actual application requirements is screened out for batch production.

[0046] S2. Pieces of skin

[0047] Slice the skins that have been screened, and the thickness of the skins is required to be 1.2-1.4mm

[0048] S3. Fall soft

[0049] Soften for 2-6 hours depending on the requirements for the Jasmine variety.

[0050] S4. Dust removal

[0051] S5. Inside cover

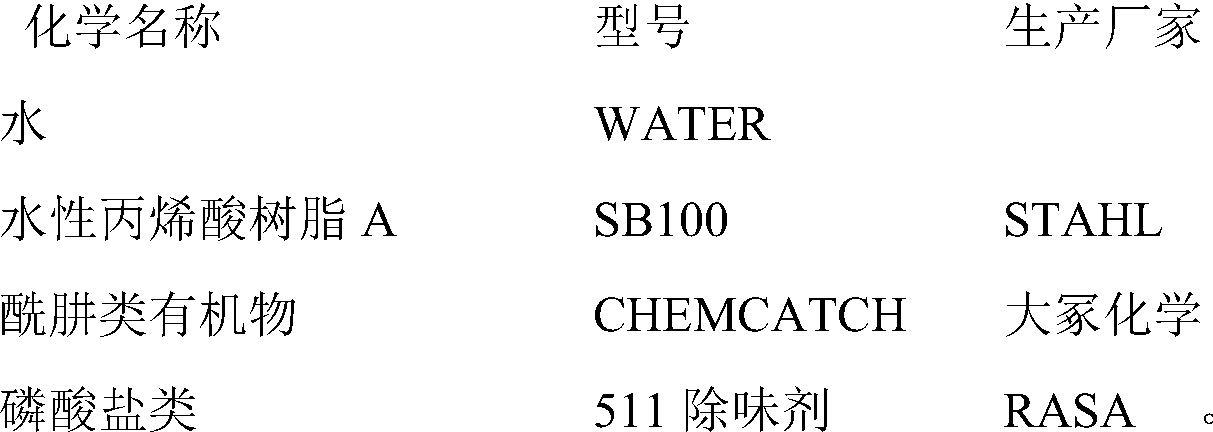

[0052] Roll the lining paste on the back of the leather with a pass-through roller coater. The inside cover slurry contains 550 parts of water, 250 parts of water-based acrylic resin A, 180 parts of hydrazide organic matter, and 20 parts of phosphate in parts by weight, totaling 1000 parts.

[0053] S6. Primer

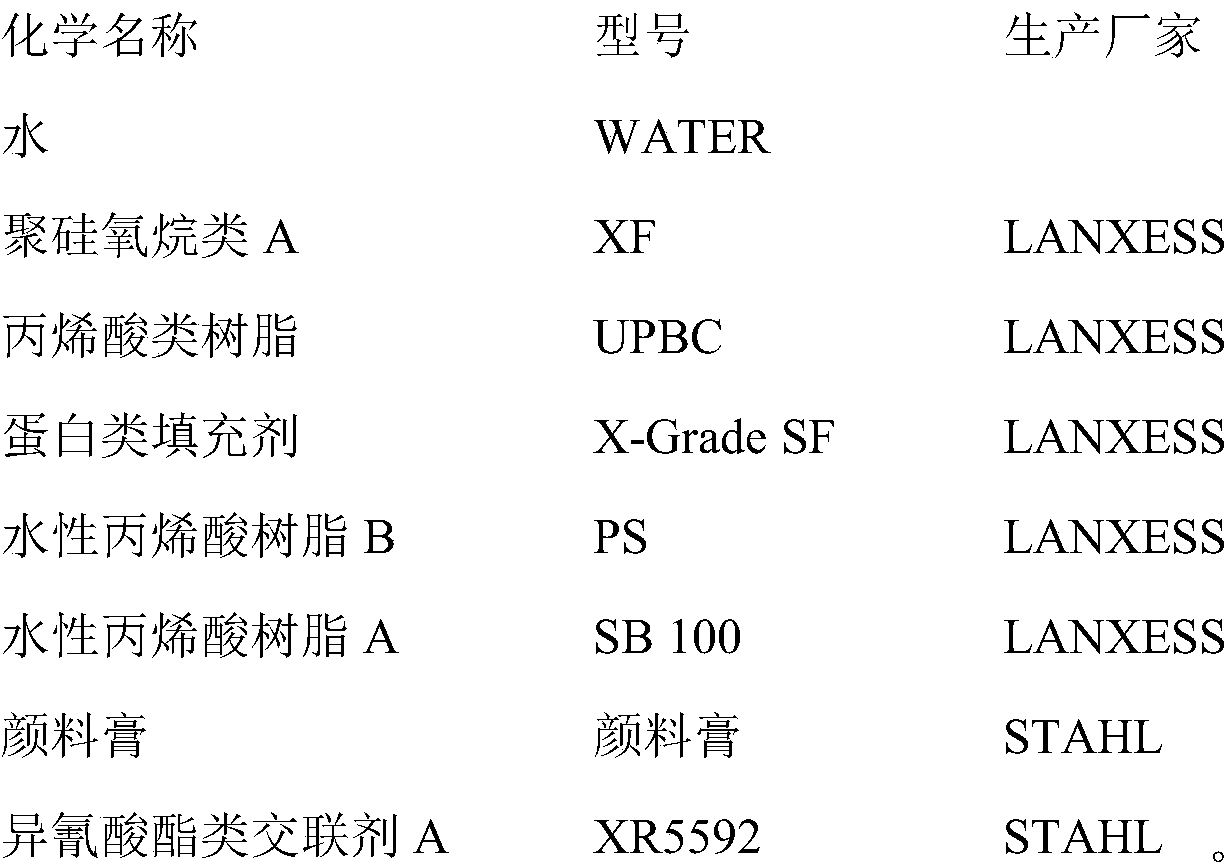

[0054] The primer coating process is carried out on the bottom layer composed of the leather surface finishing layer. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com