Carbon fiber composite reflector and manufacturing method thereof

A technology of composite materials and manufacturing methods, applied in mirrors, installations, optics, etc., can solve the problems of difficult duplication mold processing, complex duplication process, large damp heat deformation, etc., and achieve easy processing, avoid fiber printing through, and easy coating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

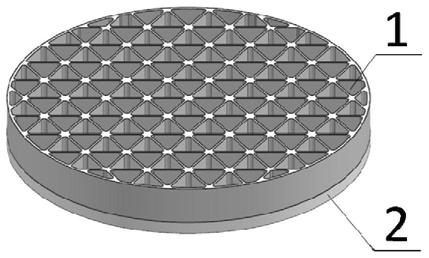

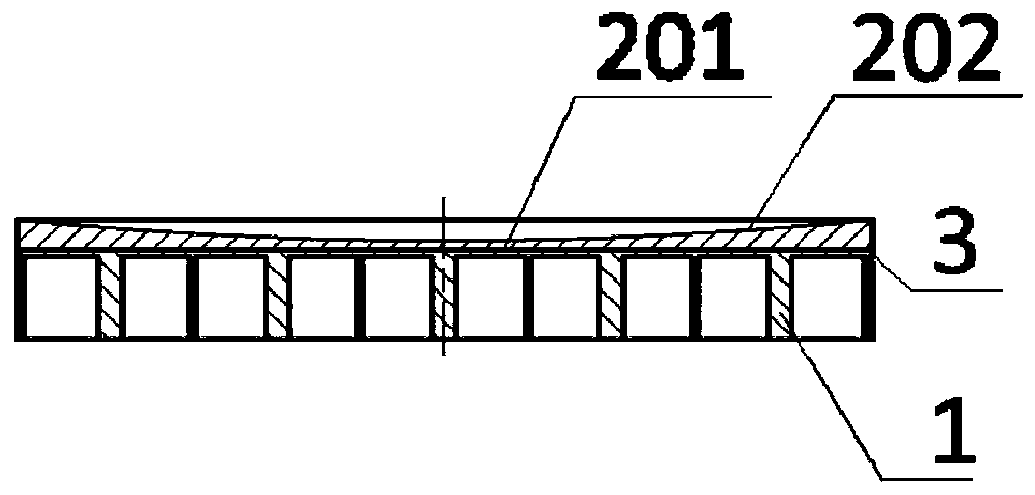

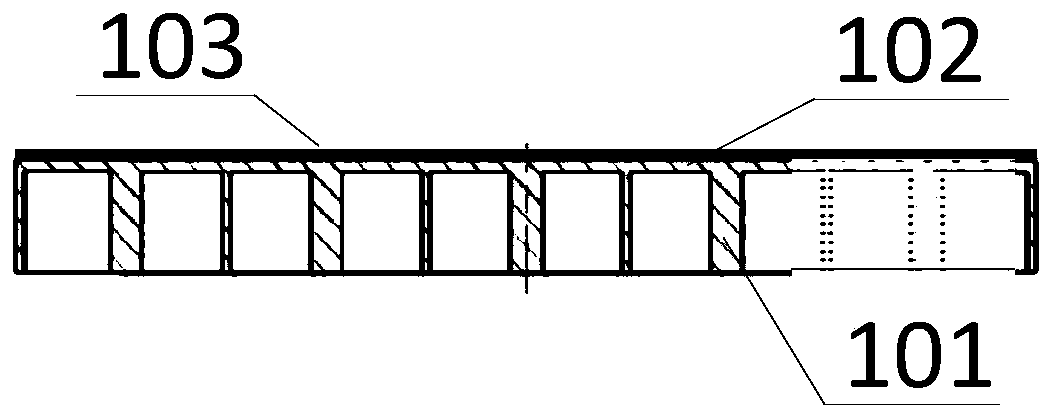

[0037] Invention idea of the present invention is:

[0038] The present invention proposes a carbon fiber composite reflector, which solves the shortcomings of the current replication technology to produce carbon fiber reflectors, such as the difficulty in processing the copy mold, the existence of fiber marks, and the large heat and humidity deformation. The two parts of the carbon fiber skeleton and the reflector panel are bonded into a monomer Reflector. The structural form of combining honeycomb and panel is adopted, and the carbon fiber composite material is integrated into a carbon fiber skeleton. Through a certain layer design, the specific stiffness of the reflector is greatly improved. Utilize the advantages of pitch-based carbon fiber / cyanate ester composite material with small linear expansion coefficient, high thermal conductivity, and thermal characteristics matching with ULE mirror panel materials to ensure good thermal stability of the mirror; the advantage of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com