Preparation method of tungsten or molybdenum-based fuel pellets dispersed with uranium dioxide core balls

A technology of uranium dioxide and fuel pellets, which is applied in the direction of reactor fuel materials, manufacturing reactors, reducing greenhouse gases, etc. It can solve the problems of inability to achieve high mixing uniformity and the proportion of binders should not be too high, and achieve a high degree of mixing , the effect of uniform mixing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

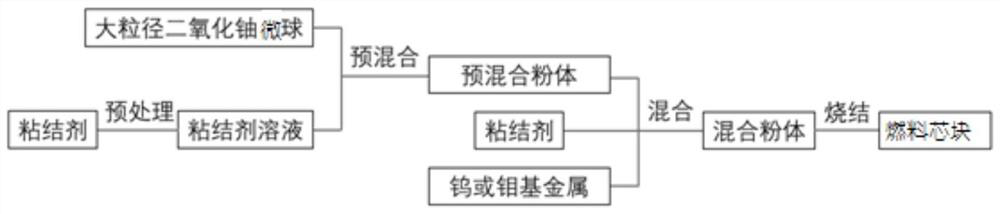

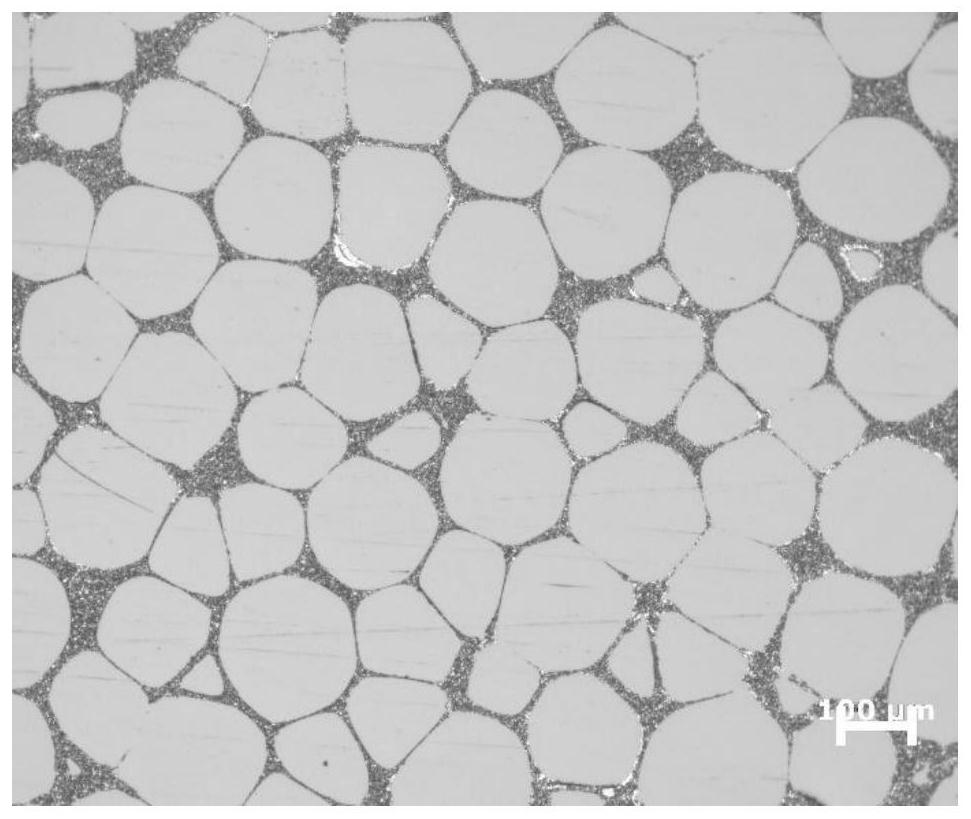

[0028] A method for preparing tungsten-based fuel pellets dispersed with uranium dioxide core balls, specifically comprising:

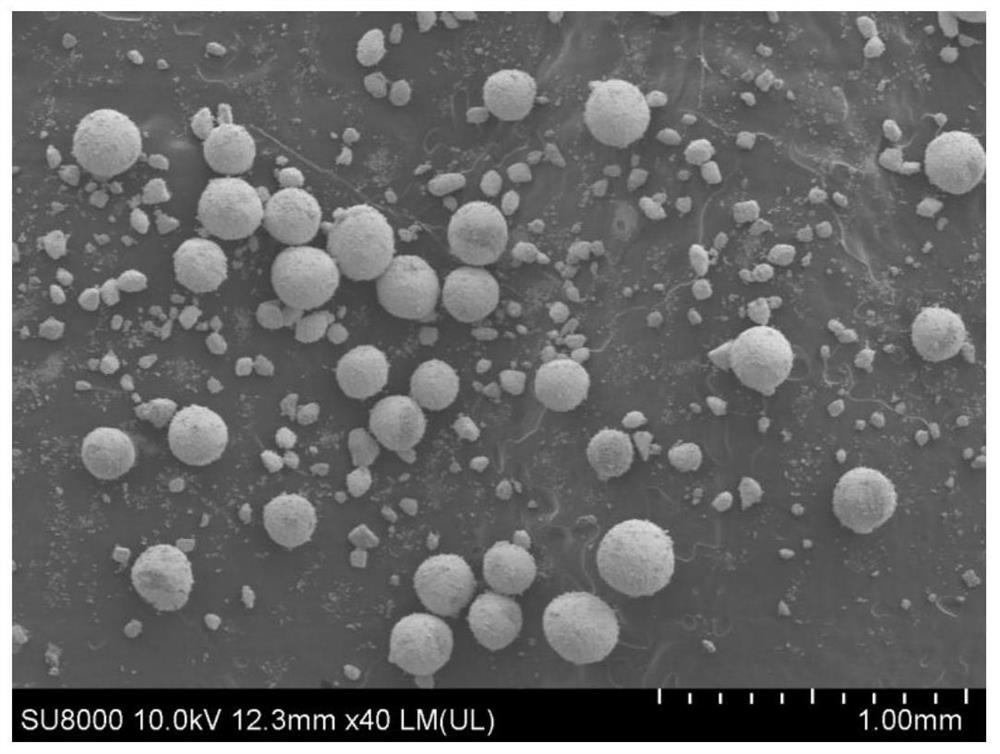

[0029] Raw material preparation: uranium dioxide microspheres with a total volume ratio of 60V% and a particle size of 200 microns, a tungsten-based metal nanopowder with a total volume ratio of 40V% and a particle size of 600nm, the binder is liquid paraffin, The total amount is 2wt% of the total mass of uranium dioxide microspheres and tungsten-based metal nanopowders, and the amount of binder in step S1 is 1wt% of the total mass of uranium dioxide microspheres and tungsten-based metal nanopowders, The amount of the binder in step S2 is 1wt% of the total mass of the uranium dioxide microspheres and the tungsten-based metal nanopowder;

[0030] The preparation of tungsten-based fuel pellets specifically includes the following steps:

[0031] S1. Dissolve liquid paraffin in acetone to obtain a binder solution, then soak the uranium dioxide microspher...

Embodiment 2

[0038] A method for preparing molybdenum-based fuel pellets dispersedly distributed with uranium dioxide core balls, specifically comprising:

[0039] Raw material preparation: uranium dioxide microspheres with a total volume ratio of 65V% and a particle size of 180 microns, molybdenum-based metal nanopowders with a total volume ratio of 35V% and a particle size of 500nm, the binder is solid paraffin, Its dosage is 1wt% of the total mass of uranium dioxide microspheres and molybdenum-based metal nanopowders;

[0040] The preparation of molybdenum-based fuel pellets specifically comprises the following steps:

[0041] S1. Dissolve solid paraffin in acetone to obtain a binder solution, then immerse the uranium dioxide microspheres in the binder solution for 30 minutes, dry and remove the acetone, and obtain a uranium dioxide core with solid paraffin evenly attached to the surface ball;

[0042] S2. Mix the uranium dioxide core balls with solid paraffin evenly attached to the s...

Embodiment 3

[0046] A method for preparing tungsten-based fuel pellets dispersed with uranium dioxide core balls, specifically comprising:

[0047] Raw material preparation: uranium dioxide microspheres with a total volume ratio of 30V% and a particle size of 1000 microns, a tungsten-based metal nanopowder with a total volume ratio of 70V% and a particle size of 200nm, and a binder of polytetrafluoroethylene Ethylene, the amount of which is 0.1wt% of the total mass of uranium dioxide microspheres and tungsten-based metal nanopowders;

[0048] The preparation of tungsten-based fuel pellets specifically includes the following steps:

[0049] S1. Dissolve polytetrafluoroethylene in acetone to obtain a polytetrafluoroethylene solution, then soak the uranium dioxide microspheres in the polytetrafluoroethylene solution for 30 minutes, dry and remove the acetone, and obtain a polytetrafluoroethylene uniformly attached to the surface Uranium dioxide cores of ethylene;

[0050] S2. Mix the uraniu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com