Catalyst for treating organic wastewater and preparation method thereof

An organic waste water and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of less than 80% activity and loss of active components, etc. Achieve the effect of improving catalytic performance, increasing contact area, and improving the ability to reduce COD in wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

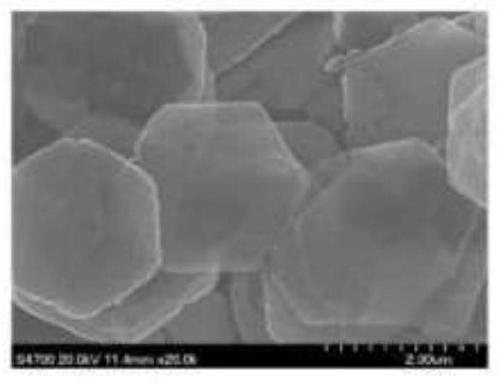

preparation example Construction

[0043] (1) Preparation of raw materials: including nitrate solution and alkali solution,

[0044] Nitrate solution: Different types of cations can be selected in different embodiments, and water is added to prepare a nitrate mixed solution with a cation weight of 1 mol,

[0045] Alkali solution: mix 3.5mol / L NaOH solution and 0.25mol / L Na 2 CO 3 Aqueous solution mixing;

[0046] (2) Mixed precipitation: Add alkali solution and nitrate solution to 70°C ionized water in a volume ratio of 1:1 to form hydrotalcite precipitation, stirring continuously until no more precipitation occurs;

[0047] (3) Aging: the hydrotalcite prepared in step (2) is aged in a water bath at 80°C for 4 hours;

[0048] (4) Suction filtration: Use deionized water to continuously wash and filter the aged hydrotalcite in step (3) until the filtered filtrate is neutral;

[0049] (5) Drying: drying the hydrotalcite obtained in step (4) to obtain a finished hydrotalcite.

[0050] A preparation method of a catalyst for tre...

Embodiment 5

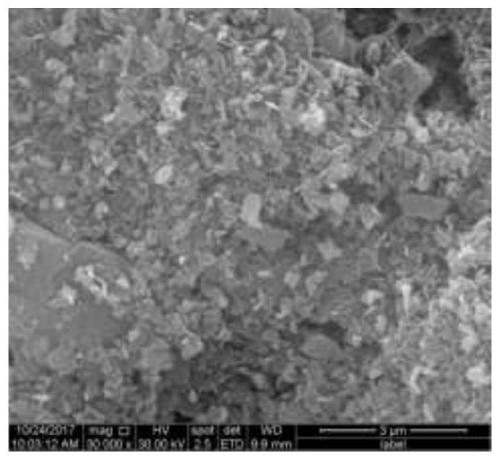

[0064] Example 5 Cu 2+ The dissolution of ions is 37.5% lower than that of Example 2. Zn 2+ The dissolution of ions is reduced by 95.5%, Fe 3+ The dissolution of ions was reduced by 84.5%.

Embodiment 4

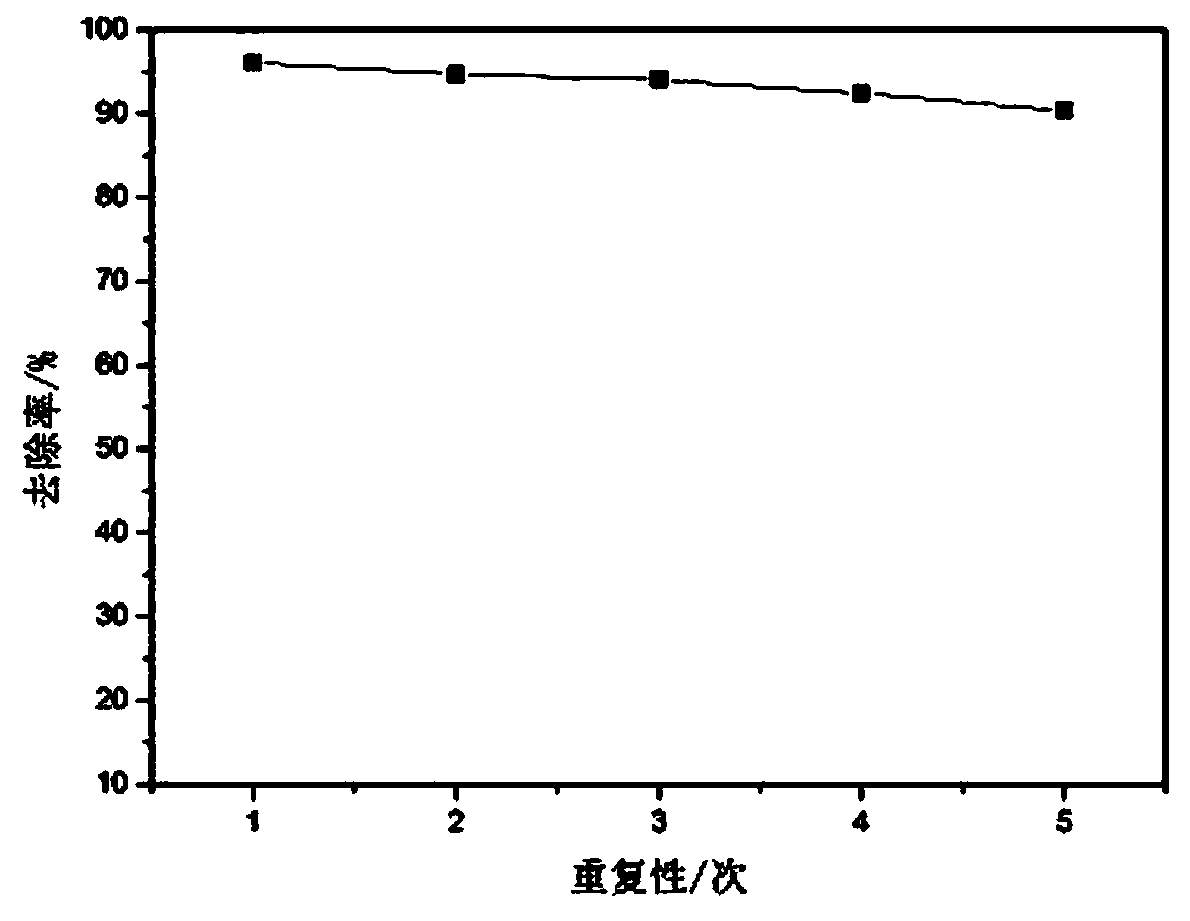

[0065] Example 4 has little effect on reducing metal elution, and the activity is basically unchanged. The removal rate of COD in simulated phenol wastewater with COD 20000mg / L is 91.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com