Graphene aerogel composite material capable of being magnetically driven as well as preparation method and application of graphene aerogel composite material

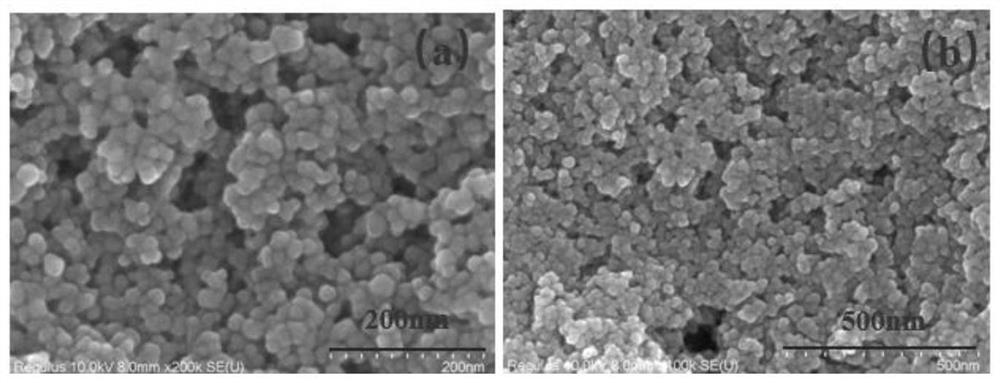

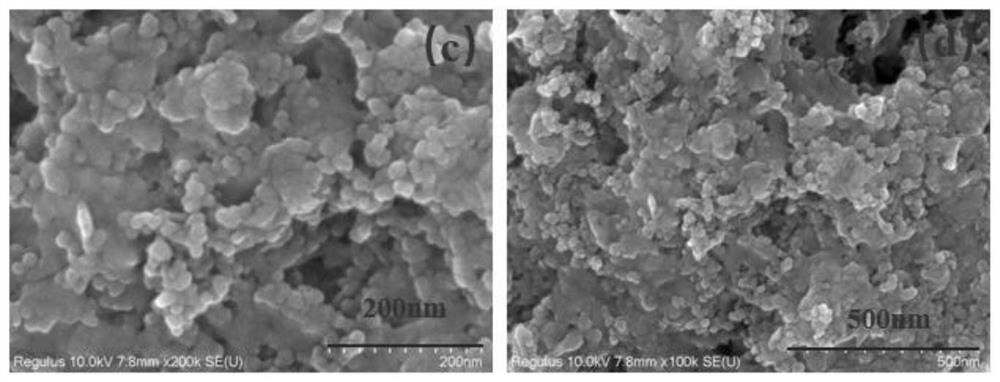

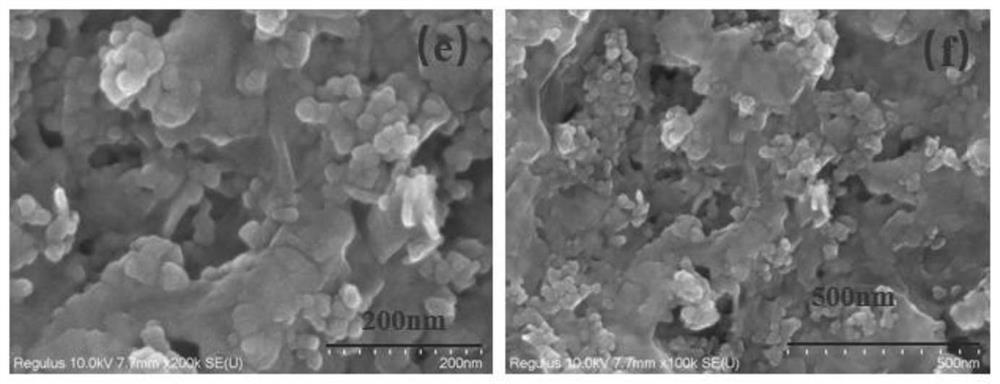

A technology of graphene airgel and composite materials, which is applied in the field of graphene airgel composite materials and its preparation, can solve the problems of non-environmental protection of photocatalysts, difficulties in recycling inorganic powder materials, self-aggregation, etc., and achieve improved photocatalytic performance. The effect of activity, uniform thickness and size, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a preparation method of a magnetically driven graphene aerogel composite material, comprising the following steps:

[0035] (1) Fe 3 O 4 Nanoparticles, bismuth salt, citric acid and deionized water are mixed to obtain a mixed slurry;

[0036] (2) adding cetyltrimethylammonium bromide solution dropwise to the mixed slurry obtained in the step (1), and stirring to obtain a precursor;

[0037] (3) drying the precursor obtained in the step (2) to obtain Fe 3 O 4 / BiOBr;

[0038] (4) the Fe that described step (3) obtains 3 O 4 / BiOBr was mixed with lysine, graphene oxide, and deionized water for a hydrothermal reaction, resulting in a magnetically actuated graphene aerogel composite.

[0039] In the present invention, unless otherwise specified, the reagents used in the present invention can be commercially available products well known to those skilled in the art.

[0040] The present invention will Fe 3 O 4 Nanoparticles, bismuth salt, cit...

Embodiment 1

[0090] A preparation method of a magnetically driven graphene aerogel composite material, the steps are:

[0091] (1) Fe 3 O 4 The preparation method of nanoparticles is as follows: 0.81g FeCl 2 ·4H 2 O, 2.0g FeCl 3 ·6H 2 O was mixed with 110 mL of deionized water to obtain a transparent orange solution, wherein the ratio of the amount of divalent iron salt to trivalent iron salt iron salt was 0.86:1; after heating the transparent orange solution to 90 °C, To the transparent orange solution, add 1 mL of ammonia water with a concentration of 28-30% ammonia every 1 min, add dropwise 6 times, carry out a metathesis reaction, and obtain a precursor; the obtained precursor is allowed to stand at 90 ° C for 1 h. Aging; after the aging, the product was centrifuged, magnetically adsorbed, washed with deionized water for 3 to 5 times, and dried in vacuum at 60 ° C for 12 h to obtain Fe 3 O 4 nanoparticles.

[0092] (2) Fe prepared in step (1) 3 O 4 0.25 g of nanoparticles wer...

Embodiment 2

[0098] A preparation method of a magnetically driven graphene aerogel composite material, the steps are:

[0099] Fe is prepared by the methods of steps (1) to (4) of Example 1 3 O 4 / BiOBr.

[0100] The Fe obtained by 0.35g described step (3) 3 O 4 / BiOBr was mixed with 200mg lysine, 30mg graphene oxide and 6mL deionized water under ultrasonic, and reacted at 160 °C for 10h to conduct a hydrothermal reaction. After pre-cooling at ℃ for 1.5 h, and freeze-drying at -70 ℃ for 24 h, the magnetically actuated graphene aerogel composites were obtained; in which Fe 3 O 4 The mass ratio of / BiOBr, lysine and graphene oxide is 52.5:30:4.5.

[0101] The magnetically driven graphene aerogel composite material prepared in this example is abbreviated as Fe 3 O 4 / BiOBr / GE-2, Fe 3 O 4 The mass ratio of nanoparticles, BiOBr and graphene is preferably 160:190:3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com