High-voltage charge-discharge and leakage circuit integrated topological structure and device for vehicle

A vehicle-used, gating circuit technology, applied in the direction of electrical devices, circuit devices, emergency protection circuit devices for limiting overcurrent/overvoltage, etc., can solve the problem of reducing system reliability, increasing overall cost, and numerous components problem, to achieve the effect of improving system reliability, increasing design margin, and reducing the number of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] As mentioned in the background art, due to the special application of military hybrid special vehicles, too many power components occupy more space, reduce system reliability and increase overall cost.

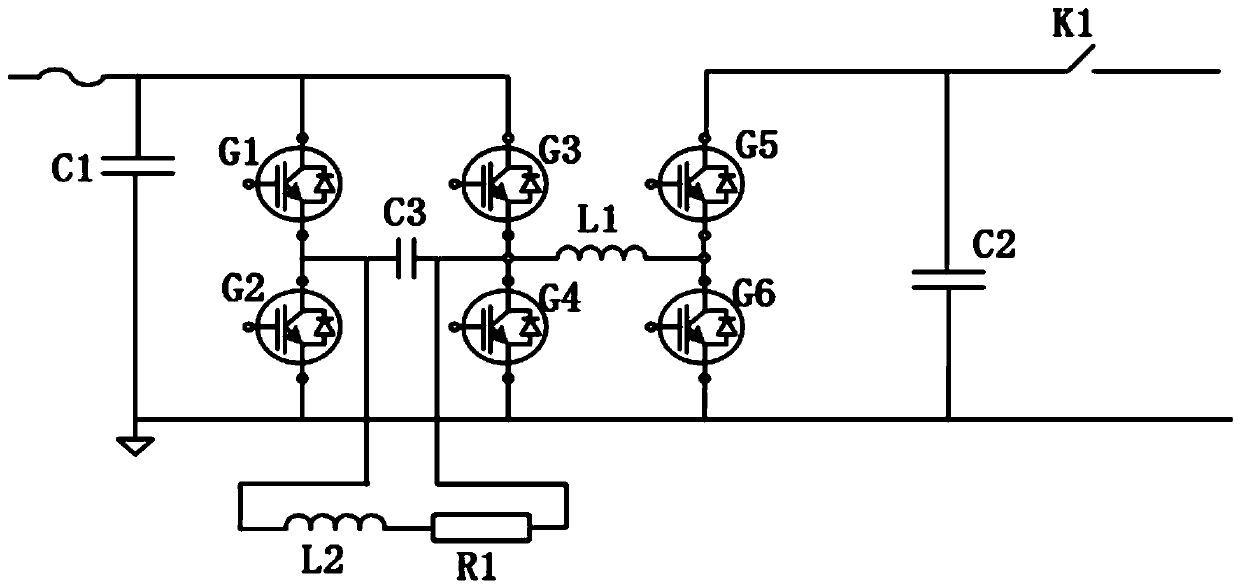

[0058] Therefore, Embodiment 1 of the present disclosure provides a gating circuit, such as image 3 As shown, the gating circuit includes six switch tubes G1-G6, a first capacitor C1, a second capacitor C2, a third capacitor C3, a first inductor L1, a second inductor L2 and a first resistor R1;

[0059] The collectors of the first switching tube G1 and the third switching tube G3 are both connected to the bus bar, the first switching tube is connected in series with the second switching tube, the third switching tube is connected in series with the fourth switching tube, and the fifth switching tube G5 The collector of the power battery is connected to the positive terminal of the power battery, the fifth switching tube has a sixth switching tube G6 connected in series...

Embodiment 2

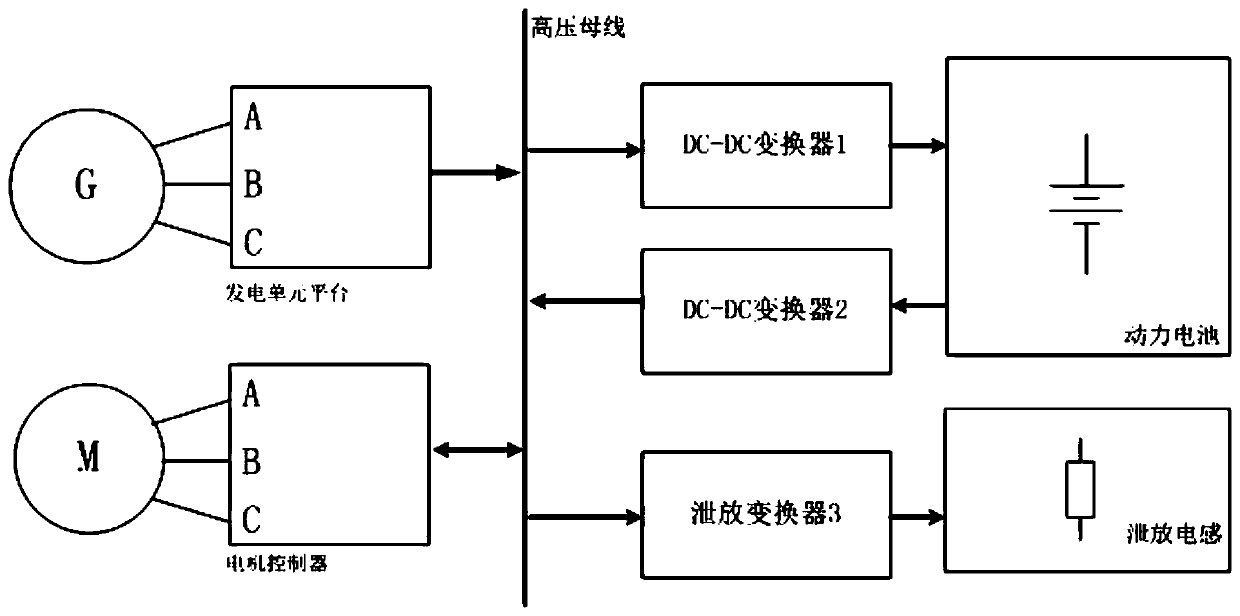

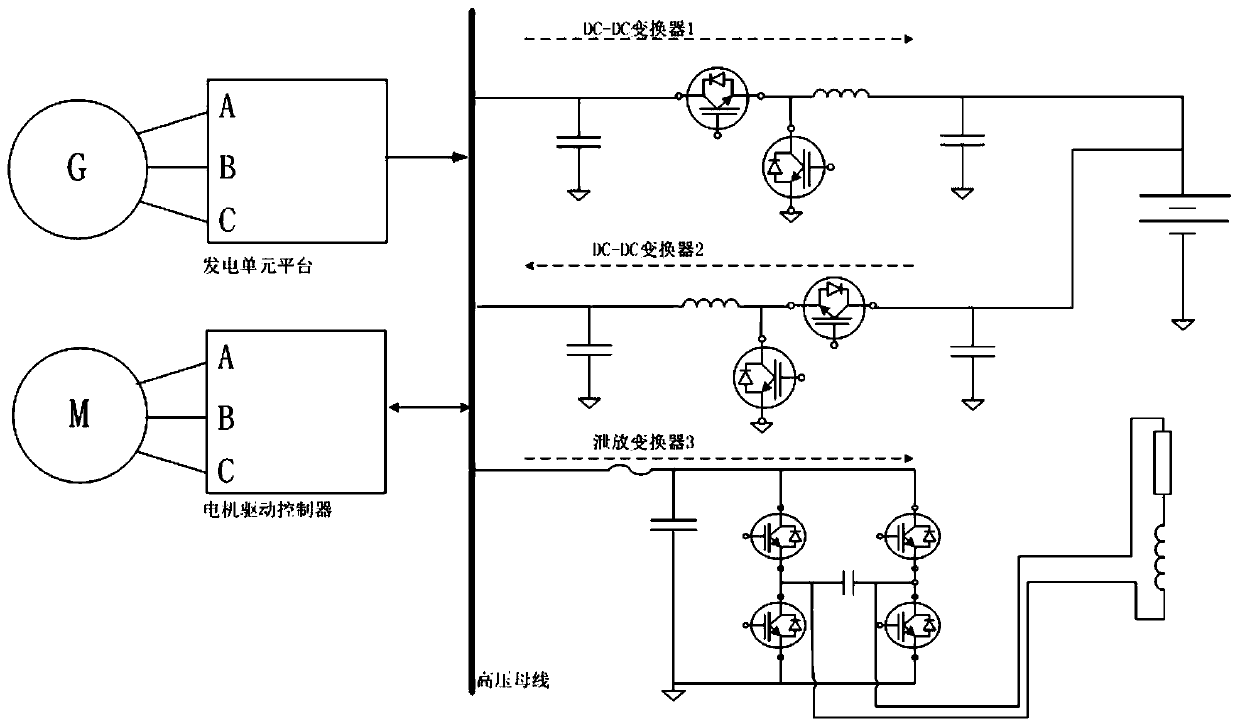

[0065] Embodiment 2 of the present disclosure provides an integrated topological structure of a high-voltage charging and discharging circuit for a vehicle, such as Figure 4 As shown, it includes a bus bar, a power battery and the gating circuit described in Embodiment 1, and the gating circuit is connected in series between the bus bar and the power battery;

[0066] By controlling the time-sharing gating and closing of the six switching tubes, the forward and reverse BUCK type DC-DC step-down energy conversion between the busbar and the power battery and the energy discharge when the busbar voltage is too high are realized.

Embodiment 3

[0068] Embodiment 3 of the present disclosure provides a vehicle busbar feeding method, which is used to charge the battery through the busbar voltage through the integrated converter, such as Figure 5 As shown, the topology described in Embodiment 2 is used.

[0069] The high-voltage bus energy passes through the G3 insulated gate bipolar triode, the body diode of the inductor L1 and G5 to realize the BUCK chopper converter, and charges the battery after being filtered by the capacitor C2 (shown by the solid arrow in the figure), and disconnects the G3 tube During this period, the G4 body diode freewheels (shown by the dotted arrow on the way).

[0070] Generally speaking, the high-voltage bus is the input terminal, and devices such as G3, G4, G5, L1, C1, and C2 form a BUCK-type chopper power supply from left to right to charge the battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com