A method for strengthening anaerobic co-digestion based on the isoelectric point of sludge using acid fermentation of food waste

A technology of food waste and isoelectric point, which is applied in chemical instruments and methods, biological sludge treatment, water/sludge/sewage treatment, etc., can solve the problems that limit the development of pretreatment technology, and achieve the degradation rate of sludge organic matter Improvement, yield improvement, and the effect of strengthening anaerobic digestion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

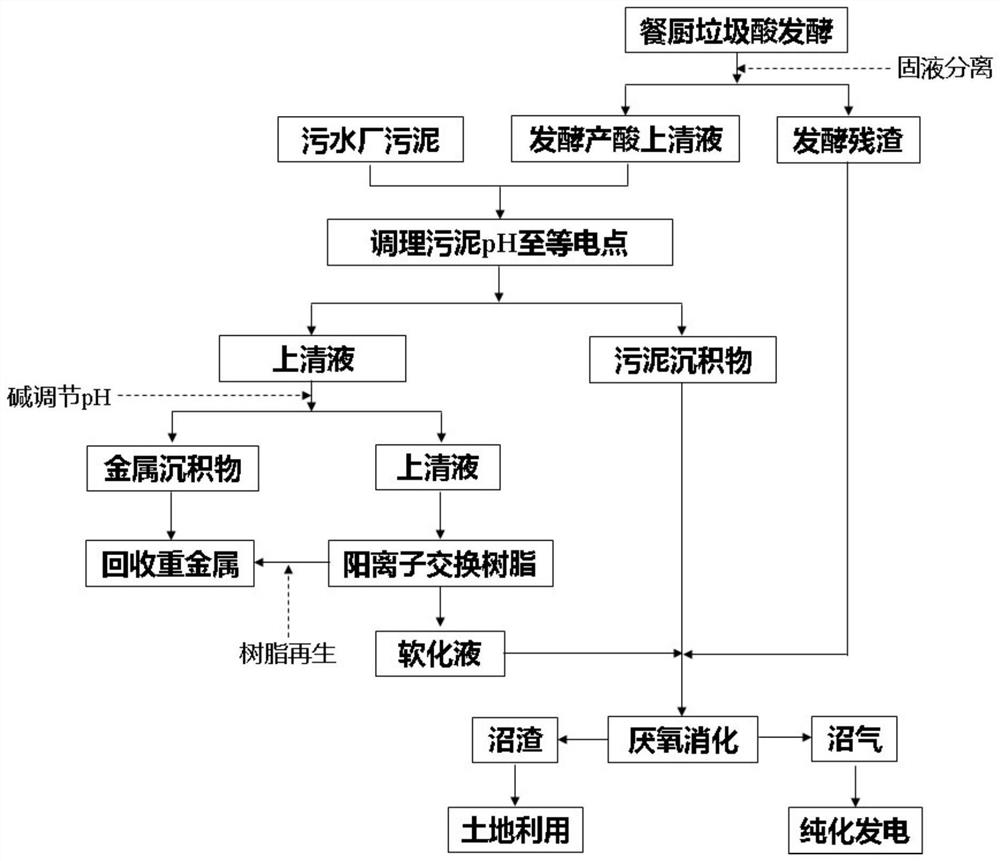

[0061] The method for strengthening anaerobic co-digestion based on the isoelectric point of sludge using acid fermentation of kitchen waste in this embodiment includes the following steps:

[0062] (1) After thermal hydrolysis pretreatment of 500g of kitchen waste, high-temperature (55°C) anaerobic fermentation for acid production for 4 days was carried out to obtain food waste fermentation acid production liquid;

[0063] (2), concentrating and enriching the food waste fermentation acid production liquid in the enrichment step (1) to make the pH<3, and collecting the fermentation acid production supernatant and the fermentation residue respectively;

[0064] (3), adjust the pH value of 500g of sludge to the isoelectric point of the sludge (pH value is 4.2) with the fermented acid production supernatant of step (2), and stir with the rotating speed of 400rpm for 4h;

[0065] (4), the sludge after conditioning in step (3) is carried out solid-liquid separation with the rotatin...

Embodiment 2

[0073] The method for strengthening anaerobic co-digestion based on the isoelectric point of sludge using acid fermentation of kitchen waste in this embodiment includes the following steps:

[0074] (1) After thermal hydrolysis pretreatment of 500g of kitchen waste, high-temperature (55°C) anaerobic fermentation for acid production for 3 days to obtain food waste fermentation acid production liquid;

[0075] (2), concentrating and enriching the food waste fermentation acid production liquid in the enrichment step (1) to make the pH<3, and collecting the fermentation acid production supernatant and the fermentation residue respectively;

[0076] (3), adjust the pH value of 500g sludge to the isoelectric point of the sludge (pH value is 3.8) with the fermented acid production supernatant of step (2), and stir with the rotating speed of 600rpm for 3h;

[0077] (4), the sludge after conditioning in step (3) is carried out solid-liquid separation with the rotating speed of 10000rpm...

Embodiment 3

[0085] The method for strengthening anaerobic co-digestion based on the isoelectric point of sludge using acid fermentation of kitchen waste in this embodiment includes the following steps:

[0086] (1) After thermal hydrolysis pretreatment of 500g of kitchen waste, high-temperature (55°C) anaerobic fermentation for acid production for 6 days to obtain food waste fermentation acid production liquid;

[0087] (2), concentrating and enriching the food waste fermentation acid production liquid in the enrichment step (1) to make the pH<3, and collecting the fermentation acid production supernatant and the fermentation residue respectively;

[0088] (3), adjust the pH value of 400g sludge to the isoelectric point of the sludge (pH value is 4.1) with the fermented acid production supernatant of step (2), and stir with the rotating speed of 800rpm for 6h;

[0089] (4), the sludge after conditioning in step (3) is carried out solid-liquid separation with the rotating speed of 10000rpm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com