Easy-to-air-slake scintillator photonic crystal and preparation method thereof

A photonic crystal and scintillator technology, which is applied in the field of nuclear radiation detection and devices, can solve the problems of preparing photonic crystals and destroying scintillators, and achieves the effects of stable structural properties, avoiding direct contact and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

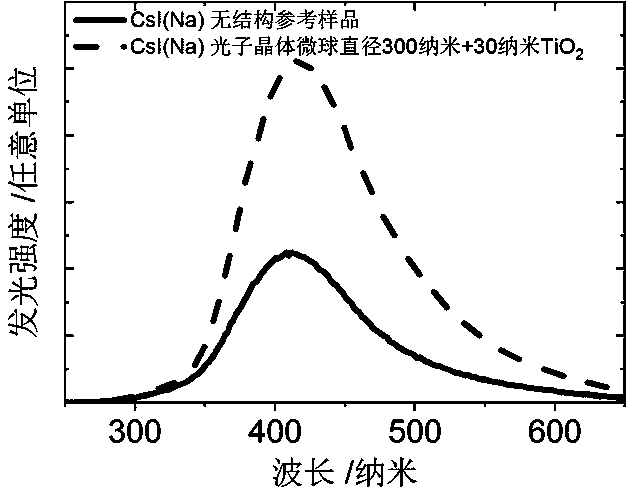

[0034] The scintillator used in this embodiment is CsI(Na), the diameter of the crystal is 30 mm, and the thickness is 2 mm.

[0035] In a dry clean room, the preparation steps are as follows:

[0036] 1) Soak the silicon wafer in a 10% sodium lauryl sulfate solution for 24 hours to form a hydrophilic monolayer on the surface of the silicon wafer.

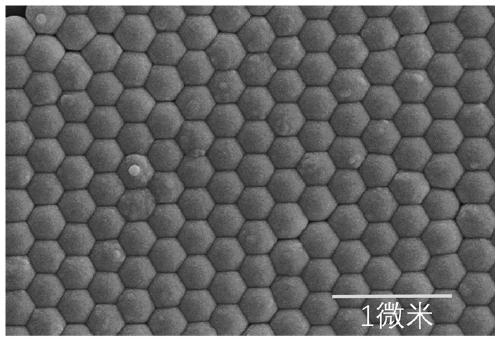

[0037] 2) Select PS microsphere colloidal particle solution with a diameter of 300nm purchased from Wuhan Huake Weike Technology Co., Ltd. and add deionized water to prepare a suspension with a mass fraction of PS microsphere colloidal particle solution of 2.5%. Take out the silicon wafer; drop three drops (about 0.15 ml) on the surface of the silicon wafer with a pipette gun, with an interval of 1-2 seconds between each drop, at this time the PS microspheres will self-assemble on the silicon wafer to form a hexagonal density. Packed periodic array structure of microspheres. The suspension of 2.5% suspension is only for the conve...

Embodiment 2

[0047]The scintillator used in this embodiment is CsI(Na), the diameter of the crystal is 30 mm, and the thickness is 2 mm.

[0048] In a dry clean room, the preparation steps are as follows:

[0049] 1) Soak the silicon chip in a 15% sodium lauryl sulfate solution for 48 hours to form a hydrophilic monolayer on the surface of the silicon chip;

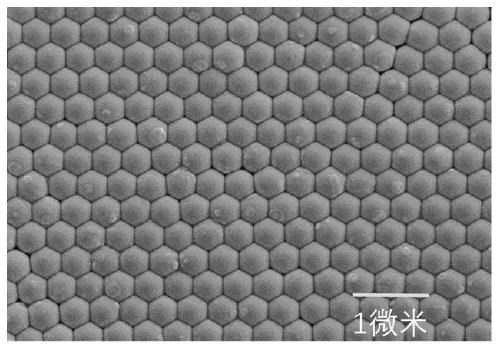

[0050] 2) Select PS microsphere colloidal particle solution with a diameter of 400nm purchased from Wuhan Huake Weike Technology Co., Ltd., add water to prepare a suspension of PS microsphere colloidal particle solution with a mass fraction of 2.5%, and pipette three drops ( About 0.15 ml), each drop is dropped on the surface of the treated silicon wafer at an interval of 1-2s, at this time, the PS microspheres will self-assemble on the silicon wafer;

[0051] 3) After the solution on the silicon wafer is dry, put the silicon wafer into the deionized water slowly; the speed of putting the silicon wafer into the deionized water is con...

Embodiment 3 to 9

[0060] Using the above steps, Examples 3 to 9 were carried out, wherein the selection of main preparation parameters and the scintillation enhancement ratio obtained from the test are shown in Table 1. The results show that for the deliquescent scintillators involved, the photonic crystal results can be obtained by using this method, and it can play the role of enhancing scintillation and luminescence.

[0061]

[0062] Table 1 Embodiment 3 to 9 parameter details

[0063] The preparation method disclosed in the present invention is not limited to deliquescent halide inorganic scintillators; it is also applicable to other deliquescent scintillators.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com