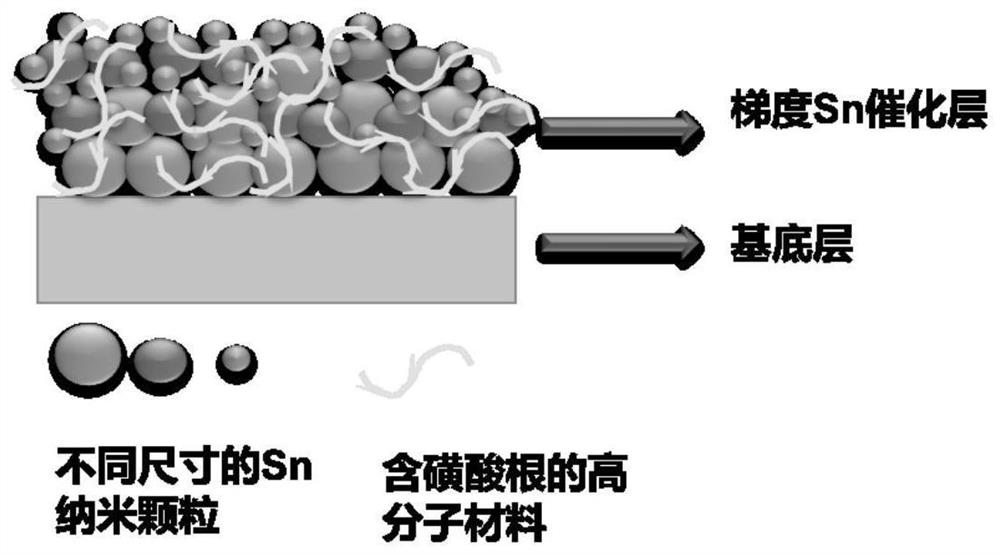

Preparation and application of a sn electrode for electrochemical reduction of carbon dioxide

A carbon dioxide and electrochemical technology, which is applied in the direction of electrodes, electrolytic components, electrolytic processes, etc., can solve the problems of failure to conduct protons, electrode current density that cannot meet the use requirements, and large catalyst particles, so as to improve Faradaic efficiency, Effect of increasing effective active area and increasing reaction current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

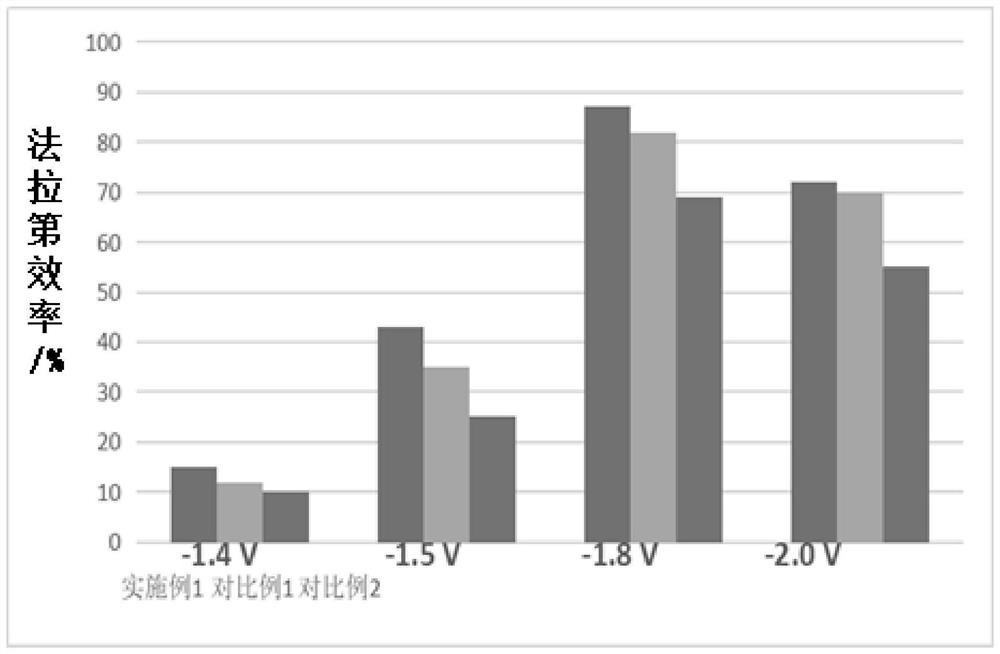

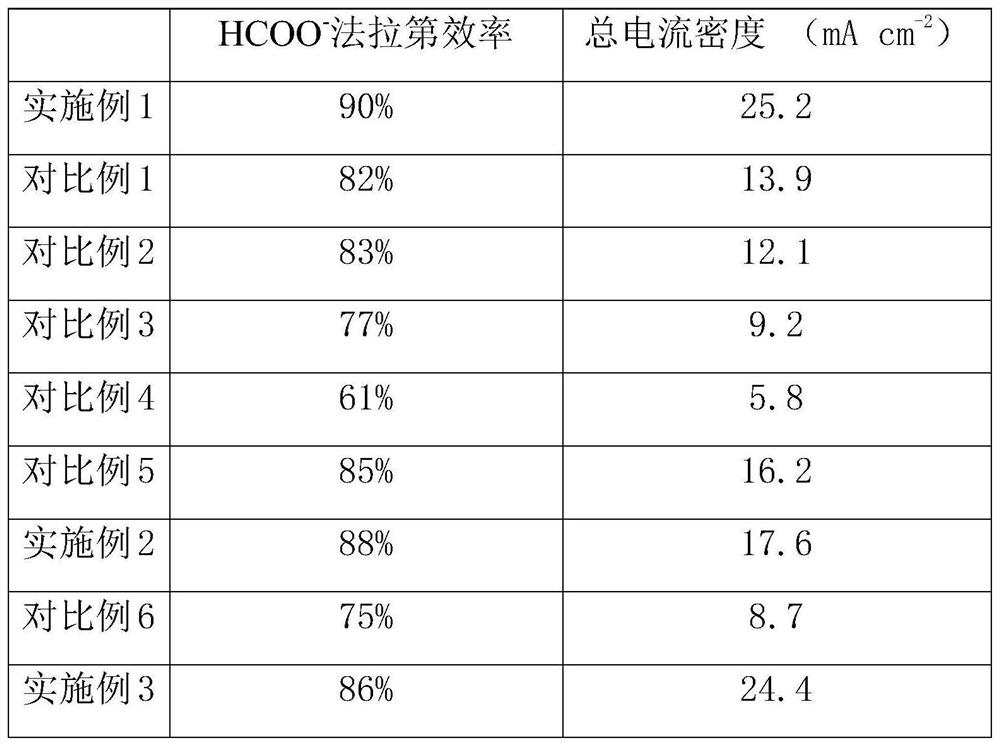

Embodiment 1

[0040] The carbon felt or carbon paper treatment process is as follows: treatment in the air at 450°C, and then degreasing treatment and cleaning in ethanol and acetone; the Sn catalyst layer is obtained by electrochemical tin plating on the surface of the above substrate by means of potential; According to the mass ratio of Sn to sulfonate-containing polymer is 2:1, SnSO 4 with H 2 SO 4 The molar ratio of 1:2, the concentration of 0.25mol / L of SnSO 4 solution, with 0.5mol / L of H 2 SO 4 and 0.1mol / L perfluorosulfonic acid resin, mixed uniformly to obtain a mixture solution as an electrolyte solution; at a constant current density of -100mA / cm 2 , deposited for 600s, then at constant current density -60mA / cm 2 , deposited for 600s, and finally at a constant current density of -20mA / cm 2 , deposited for 300s; the substrate with the deposited Sn layer was reduced in 0.3mol / L KCl at -1.6V for 1800s; after washing and drying, it was placed in a vacuum oven at 150°C to obtain ...

Embodiment 2

[0052] The carbon felt or carbon paper treatment process is as follows: treatment in the air at 450°C, and then degreasing treatment and cleaning in ethanol and acetone; the Sn catalyst layer is obtained by electrochemical tin plating on the surface of the above substrate by means of potential; According to the mass ratio of Sn to sulfonate-containing polymer is 2:1, SnSO 4 with H 2 SO 4 The molar ratio is 1:2, the concentration is 0.25mol / LSnSO 4 solution, with 0.5mol / LH 2 SO 4 and 0.05mol / L sulfonated polysulfone resin, mixed evenly to obtain a mixture solution as an electrolyte solution; under N2, the constant current density is -100mA / cm 2 , deposited for 600s, then at constant current density -60mA / cm 2 , deposited for 800s, and finally at a constant current density of -20mA / cm 2 , deposited for 500s; the substrate with deposited Sn layer was placed in 0.3mol / L NaHCO 3 Reduction at -1.6V for 1800s; washing, drying, and drying in a vacuum oven at 150°C to prepare an...

Embodiment 3

[0056] The carbon felt or carbon paper treatment process is as follows: treatment in the air at 450°C, and then degreasing treatment and cleaning in ethanol and acetone; the Sn catalyst layer is obtained by electrochemical tin plating on the surface of the above substrate by means of potential; According to the mass ratio of Sn to sulfonate-containing polymer is 5:1, SnSO 4 with H 2 SO 4 The molar ratio of 1:2, the concentration of 0.25mol / L of SnSO 4 solution, with 0.4mol / L of H 2 SO 4 and 0.1mol / L sulfonated polysulfone resin, mixed evenly to obtain a mixture solution as an electrolyte solution; at a constant current density of -100mA / cm 2 , deposited for 600s, then at constant current density -60mA / cm 2 , deposited for 600s, and finally at a constant current density of -20mA / cm 2 , deposited for 300s; the substrate with deposited Sn layer was placed in 0.5mol / L KHCO 3 Reduction at -1.6V for 1800s; washing, drying, and drying in a vacuum oven at 150°C to prepare an el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com