Transformer and preparation method thereof

A transformer and magnetic core technology, applied in the field of transformers, can solve the problems of low efficiency, poor stability and long magnetic circuit of the transformer, and achieve the effects of reducing the length of the magnetic circuit, reducing the number of coil turns, and reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

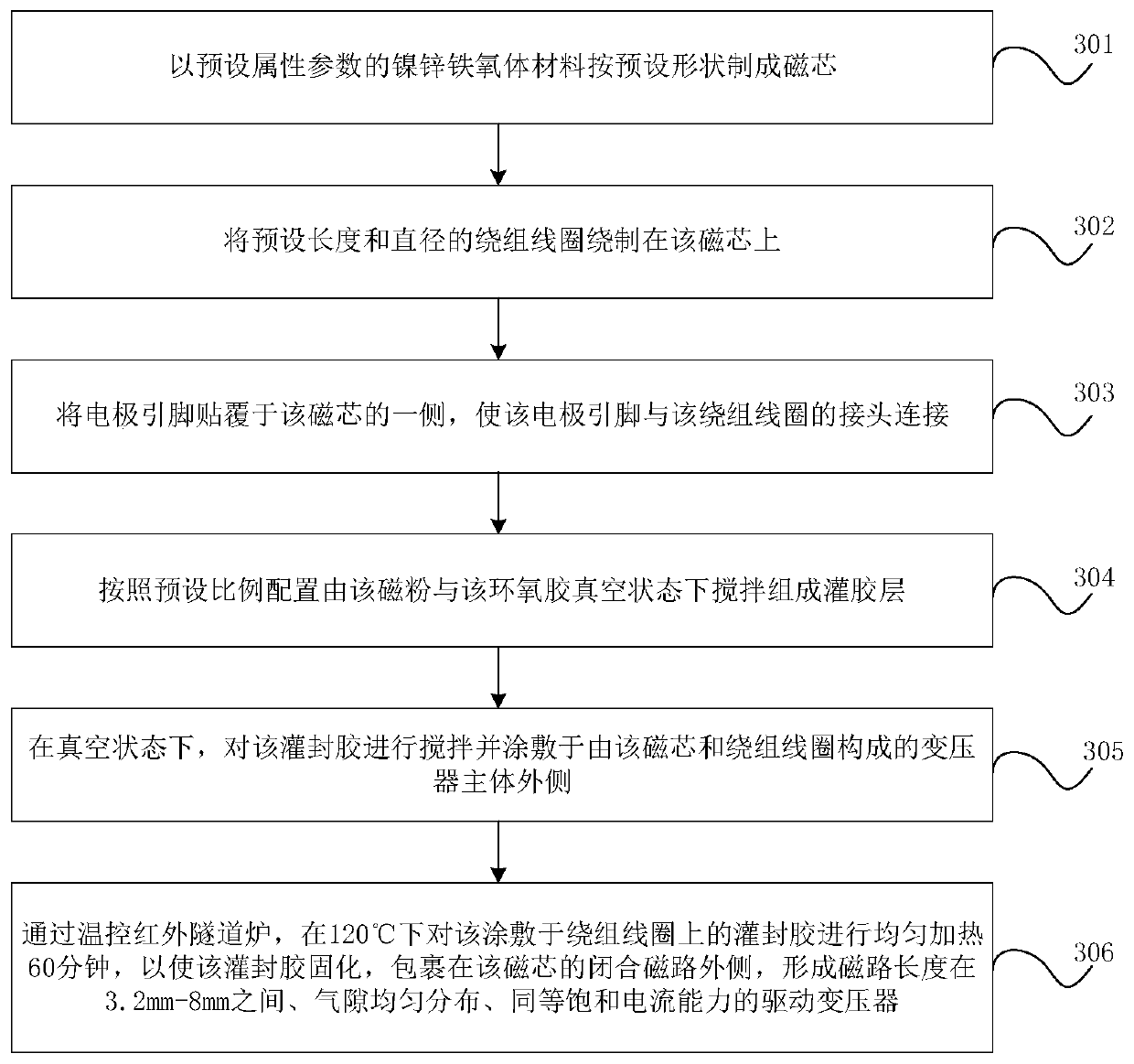

Method used

Image

Examples

Embodiment Construction

[0033] Specific embodiments of the present disclosure will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present disclosure, and are not intended to limit the present disclosure.

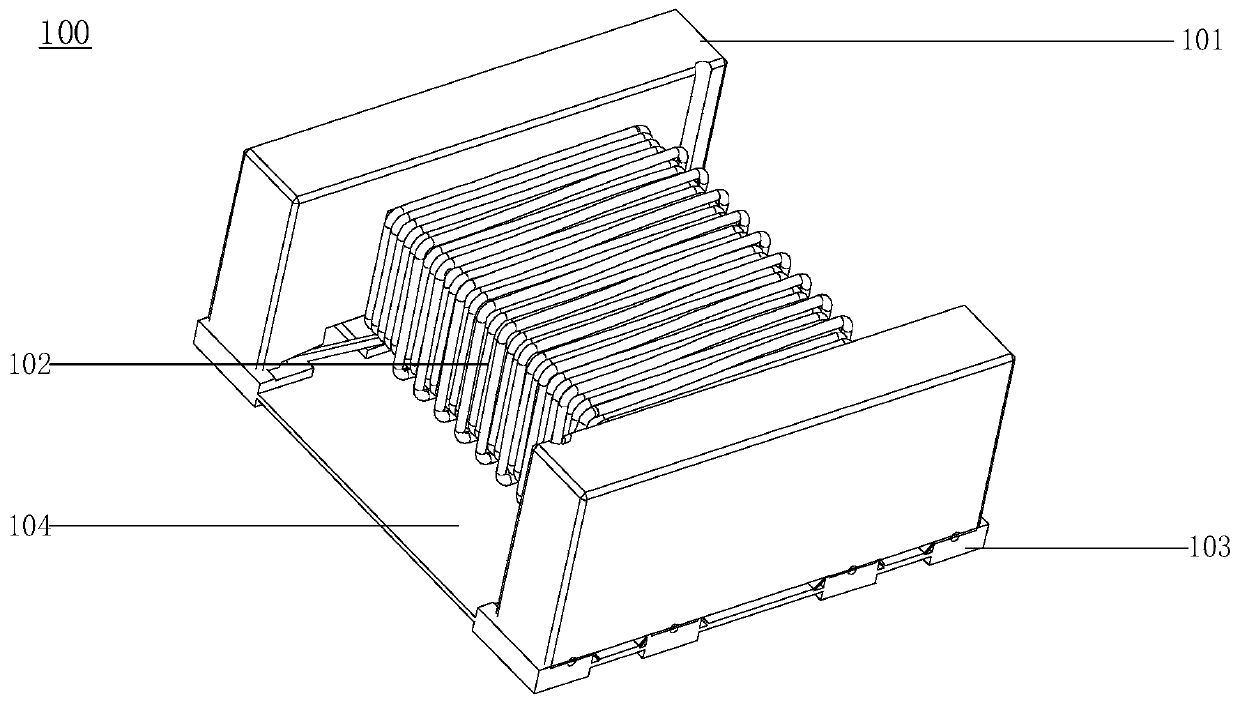

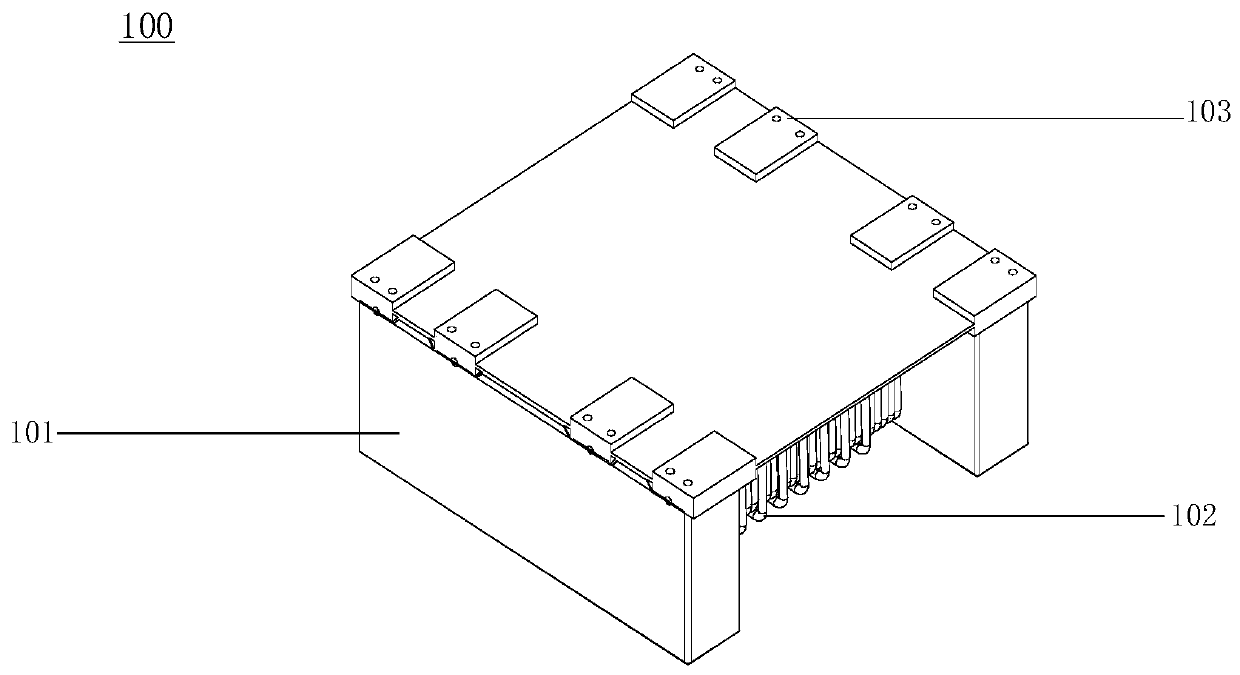

[0034] figure 1 is a structural schematic diagram of a transformer front according to an exemplary embodiment, as shown in figure 1 As shown, the transformer 100 includes: a transformer body (including a magnetic core 101 and a winding coil 102 ), an electrode pin 103 and a potting layer 104 , and the winding coil 102 is wound on the magnetic core 101 . The magnetic core 101 refers to a sintered magnetic metal oxide composed of various iron oxide mixtures (for example, manganese-zinc ferrite and nickel-ferrite are typical magnetic core materials), which are usually used in various electronic equipment coils and transformers. The coils are insulated from ea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com