Preparation method of silicon drift detector

A silicon drift detector and silicon substrate technology, which is applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the difficulty of ultra-shallow junction preparation process, the surface damage of silicon substrate, and the inability to completely repair it, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

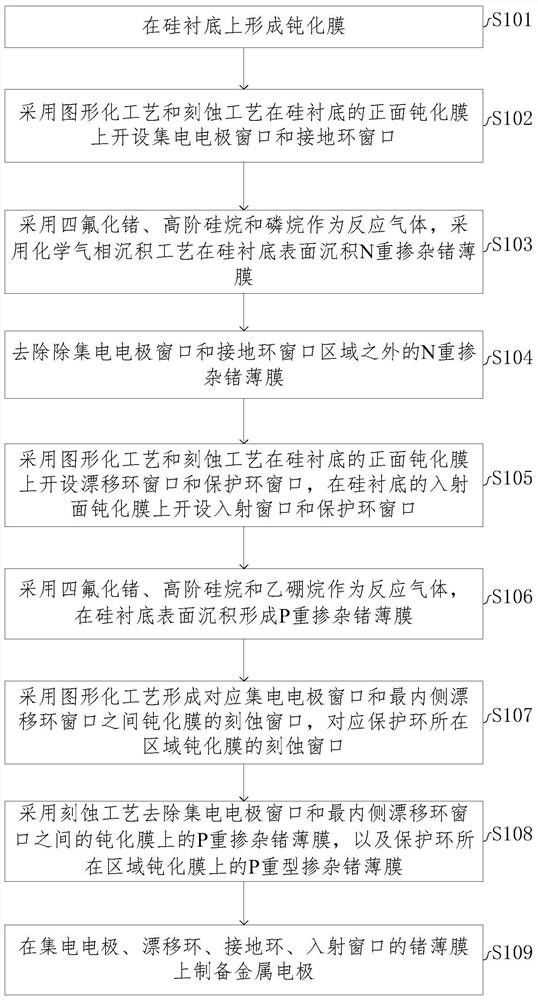

[0037] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

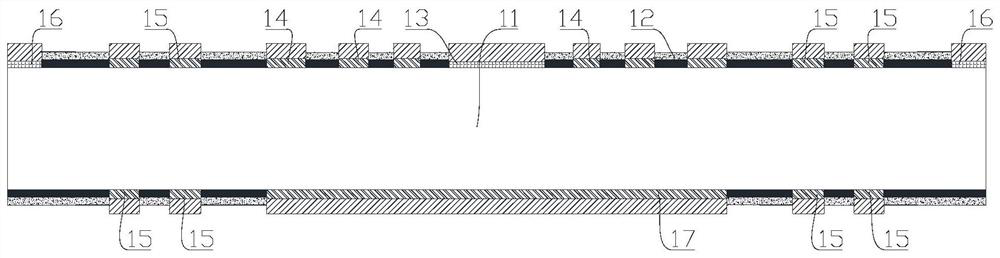

[0038] figure 1 is a schematic diagram of the junction cross-section of the silicon drift detector provided in the embodiment. Such as figure 1 As shown, the silicon drift detector provided in this embodiment includes an N-type doped silicon substrate 11 , passivation films 12 and functional regions disposed on both surfaces of the silicon substrate 11 .

[0039] The functional area includes an N-type heavily doped collector electrode 13, a P-type heavily doped drift ring 14, a P-type heavily doped guard ring 15, and an N-type heavily doped grounding ring 16 arranged on one side of the silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com