Germanium tetraflouride and hydrogen mixtures for an ion implantation system

A technology of ion implantation and germanium tetrafluoride, which is applied in ion implantation plating, electrical components, vacuum evaporation plating, etc., can solve the problems of shortened service life, reduced arc current of ion source, reduced performance and service life of ion source, etc. problems, to achieve the effect of reducing coating or deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

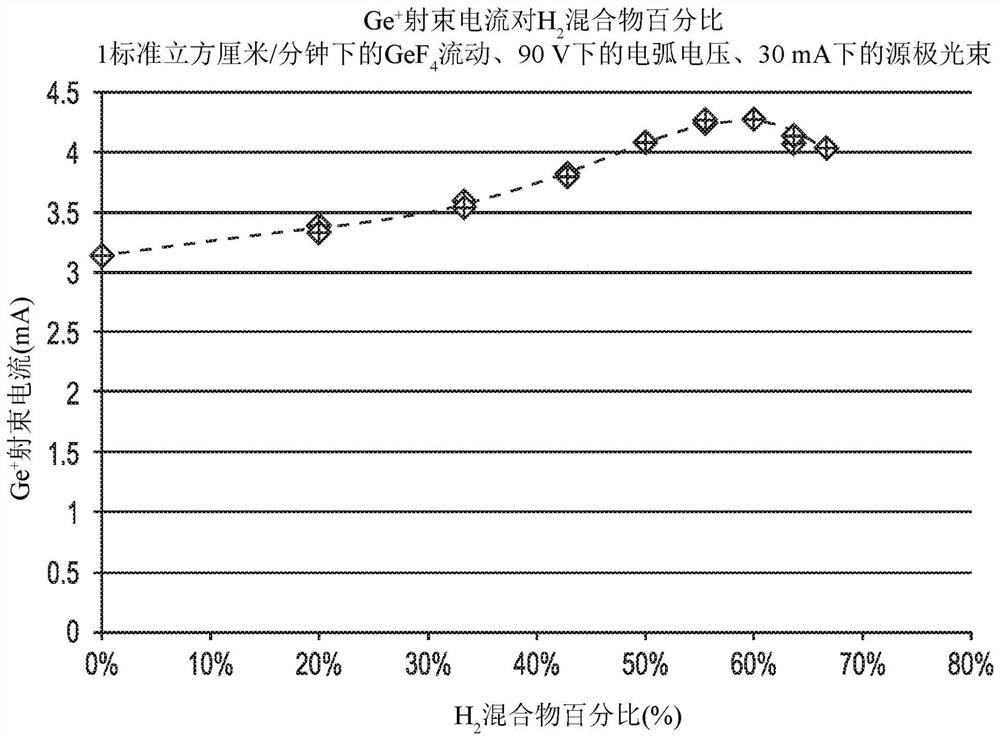

[0085] Use GeF 4 / H 2 Ion implantation of mixtures (beam current)

[0086] An ion implantation apparatus having the following features: The implant test vertical of an indirectly heated cathode (IHC) source with a tungsten arc chamber and liner was under an arc voltage (ArcV) of 90V and a source beam of 30mA operate. into the GeF implanted in the chamber 4 The flow was maintained at a constant rate of 1 sccm. to the H in the chamber 2 The mix varies from 0% to 67%. With the H in the chamber 2 The beam current is measured as the percentage of the mixture is varied. The results are shown in image 3 middle.

example 2

[0088] Use GeF 4 / H 2 Ion implantation of the mixture (cathode weight change)

[0089] The ion implanter according to Example 1 was operated at various arc voltages (ArcV) at 90V, 75V and 60V and source beam at 30mA. into the GeF implanted in the chamber 4 The flow was maintained at a constant rate of 1 sccm. to the H in the chamber 2 The percentage mixture varies from 0% to 56%. The rate of weight change (grams / hour) of the cathode was measured after the run period. The results are shown in Figure 4 middle.

example 3

[0091] Use GeF 4 / H 2 Ion implantation of mixtures (beam spectroscopy)

[0092] The ion implanter according to Example 1 was operated at an arc voltage of 90 V and a source beam of 30 mA. into the GeF implanted in the chamber 4 The flow was maintained at a constant rate of 1 sccm. to the H in the chamber 2 The percentage mixture was varied at 0%, 50% and 67%. AMU beam spectroscopy is performed, allowing comparison of changes in beam current for various ion species. The results are shown in Figure 5 middle.

[0093] aspect

[0094] Aspect 1. A method for providing an ion implantation chamber containing germanium tetrafluoride (GeF 4 ) and hydrogen (H 2 ) a gas mixture of gases to a first gas supply assembly comprising: one or more 4 and H 2 A fluid supply package, wherein the assembly is configured to provide a GeF-containing 4 with H 2 gas mixture, where H 2 present in an amount ranging from 25% to 67% by volume of the gas mixture, or GeF 4 and H 2 With vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com